The EDC fixed blade proves itself more than just a pretty face.

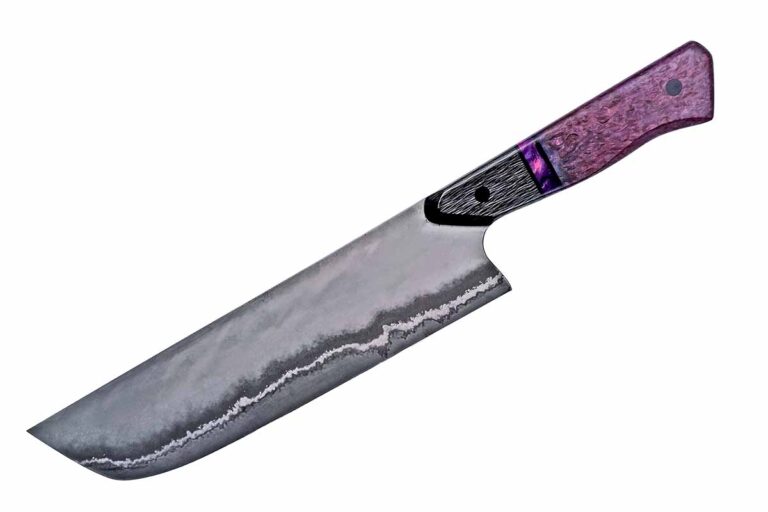

After finding First Degree Forge’s website, I reached out to Joshua Brown about testing one of his knives for “Spec Sheet.” He agreed and sent me his EDC Fighter. The shape really caught my eye, along with the blue-and-black handle. The grinds are symmetrical from side to side. I checked the handle for any epoxy gaps and found none, though I did find a few areas that might cause a hot spot or two while cutting.

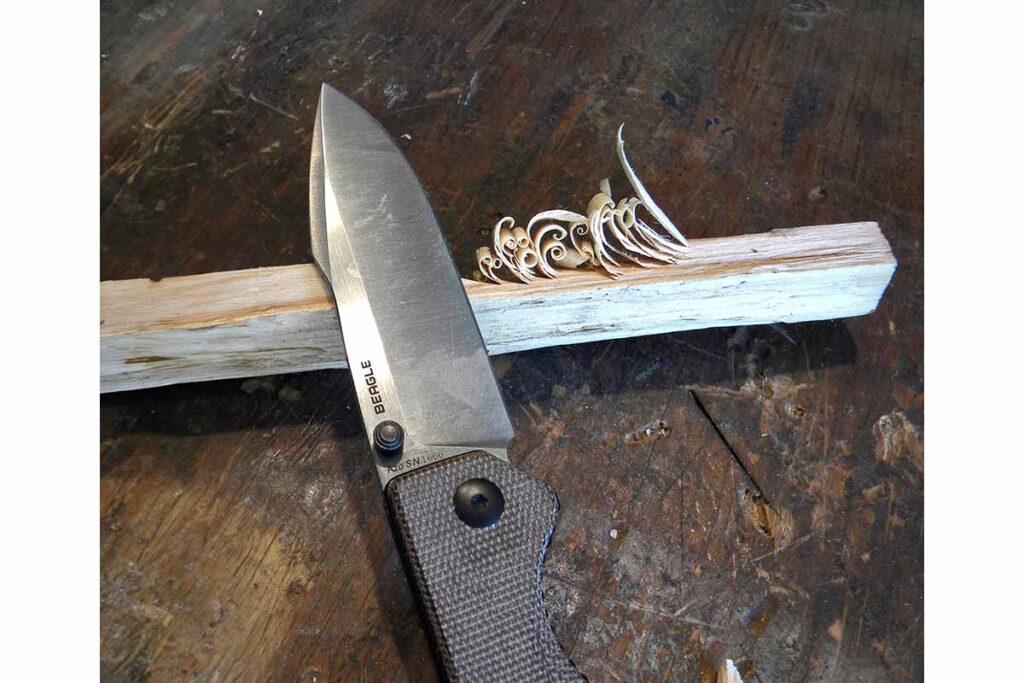

Light Cutting Tests

I went straight to the 20-pound bond copy paper for the initial sharpness check. The EDC Fighter zipped through the material quickly and repeatedly. I had to really concentrate on moving my fingers quickly so I didn’t leave any DNA on the paper or the knife. Joshua’s blade is very sharp indeed.

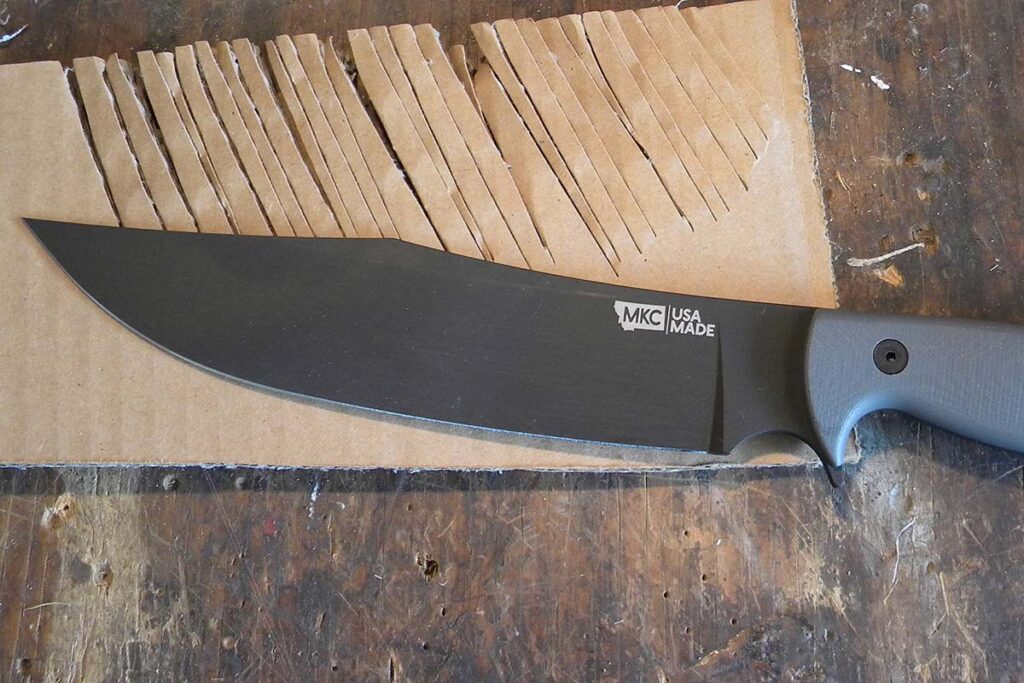

I had an extra box to pull a slicing piece from. The cardboard parted quickly. I could feel some friction as I finished the cuts. It was the medium dragging on the thick blade spine, giving the cardboard a slight curl. However, there was no slowdown in cutting.

A piece of 8-ounce leather was next. The EDC Fighter sliced it smoothly and aggressively. I could hear every crunching slice, a sound that brings a smile to my face. The handle was comfortable but felt a tad thick for my hand.

I rolled right into some skiving with the same leather. The edge crunched into the material cleanly. Overall, the EDC Fighter was quite controllable at keeping the spacing between slices even. The flat-ground blade indexed perfectly off my finger.

Heavy Cutting Tests

Whittling time! The edge produced some thick curly-cues and wanted to bite deep into the wood (there was some possible wood grain deflection). The handle made for a secure cutting grip but the steel near the choil was sharp on my skin. A little sandpaper would remove the unwanted sharpness.

Next on the menu was some baton work on a knotted pine 2×4. The large handle was comfortable and stopped any shock from transferring to my hand. The blade drove smoothly through the wood with little damage—only a little smear on the finish.

The sharpness test on sisal rope awaited. The EDC Fighter crunched its way through 190 cuts. I found that the thumb rest also had a sharp edge to it—again, an easy fix with sandpaper. The handle was comfy and the palm swells worked great.

The final paper slice was barely different from the first. What little problem there was mostly was caused by the paper picking up some dampness in the air. The edge remained very sharp.

Last of all was my regular semi-destructive test—whacking the edge into a whitetail deer antler. I gave the knife 30 good antler chops and didn’t hurt the edge at all. Heat-treatment grade: great!

Botton Line

The EDC Fighter is a very nice knife, comfortable to hold and an outstanding performer.

Changes

Soften the previously mentioned non-blade sharp edges where fingers or thumb meet steel.

EDC Fighter Specs

Maker: Joshua Brown of First Degree Forge

Blade Length: 4”

Blade Material: 1084 carbon steel

Blade Finish: Blackened

Blade Grind: Flat w/fuller

Blade @ Thickest: 1/8”

Blade @ Widest: 1.5”

Handle: Blue-and-black G-10

Handle Pins: .25” black Micarta®

Spacers: Blue-and-black G-10

Overall length: 9.5”

Sheath: Leather

Maker’s price: $350

Read More Knife Reviews:

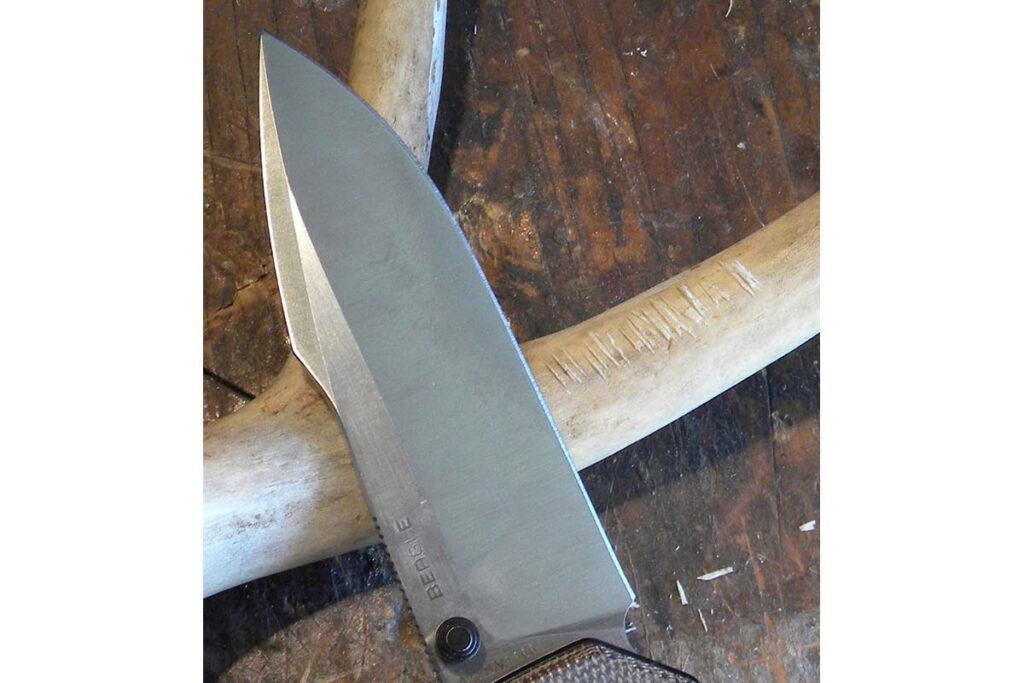

- Oknife Beagle Review

- Versa Rescue Knife Review

- Knife Review: CRKT Bamboozled

- M-1 Folder Review: How Good Is This Folder?