Here’s plenty of proof that a fillet knife can be put to extreme use, and still be a work of art.

The following is written by Tom Carpenter, and reprinted from the June 2013 issue of BLADE® Magazine.

Filleting fish under wet, sometimes salty conditions isn’t the kind of work or environment you want for your best knives. So you might suffer through with a mass-produced imitation of the real thing. But there’s no need to use an inferior tool. Consider the fish and fillet knives of Phil Wilson, Todd Kopp, Kevin D. Cross and John Cammenga of White River Knife & Tool. First, let’s get right down to the fish knife fundamentals.

Knifemaker Phil Wilson’s “Shelter Cove” fillet knife (left) sports a 7-inch N690 blade, a fiddleback-maple handle and red spacers. He says a fillet knife should have some flexibility and be ground thin.

The basic features that make for a functional and efficient fillet knife are: a comfortable, secure grip that won’t slip and slide in your hand while doing wet, slimy chores; a sharp blade that is relatively thin and flexible for precision work, and holds an edge; and materials that can stand up to abuse like moisture, blood, and frequent washing and drying.

Wilson, Kopp, Cammenga and Cross craft fish and fillet knives that fit all these criteria and more. Here’s where they put their focus.

Working under the business name Seamount Knife Works, Wilson has been making fillet knives for almost 30 years. “A simple design is best,” he says, “clean and smooth without a lot of holes and crooks and crannies to get packed up with gunk. A good finger guard and a butt end on the handle prevent slippage under wet and slimy conditions.”

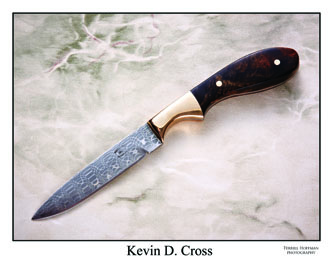

As far as the stainless-damascus blade Kevin D. Cross used for his bird and trout knife (left), the maker says there is a segment of sportsmen who appreciate a beautiful and functional knife. The piece also includes a desert-ironwood handle and bronze bolster. His list price: $400. (Hoffman photo)

As for blade material, “stainless steel is mandatory,” stresses Wilson. “I have used 440C, 154CM, AEBL, CPM-S90V, 12C27, CPM-S60V, CPM-S30V and CPM-154. Yes CPM-S90V—it still makes an awesome fillet knife, but now I feel it is overkill for the application. Given proper heat treatment, they all make a good fillet knife. These days I am using CPM-154, CPM-S30V and N690 mostly. These steels are in pretty much the same category for edge holding and ductility. A [reading] of 60 HRC seems to be the best target hardness for all of them.”

Blade characteristics are important, too. “A fillet knife should have some flexibility and be ground pretty thin,” says Wilson. “I like a springy feel in the first half of the blade from the tip back. Flex is a function of the blade geometry rather than hardness or steel grade.

Mike Mooney’s “Coho” model (left) won Best Fillet Knife at the 2011 Professional Knifemakers Association Show. It sports a 6-inch CPM-S30V blade, a dyed and stabilized redwood burl handle, and a 416 stainless steel bolster. (Buddy Thomason photo)

“Blade lengths from 6 to about 9 inches will handle most fillet work,” he adds, “and also double as boning, slicing and carving knives in the kitchen. Edge holding on a fillet knife is not quite as important as on a hunting/utility knife. A fillet knife can clean a box of fish and then get touched up at home or on the boat later. So a little lower hardness can be traded off for some added ductility on a thin, flexible blade.”

Non-Slip Grips

Handle material is critical. “I’m using mostly canvas Micarta® handles,” states Wilson. “An option is G-10. Both are naturally non-slip and do not soak up moisture.”

Kopp earned “Best Fillet Knife” honors at the 2010 Professional Knifemakers Association Show with his damascus fillet knife. He strayed from traditional stainless steel for his award-winning knife, opting instead for a damascus of 1084 and 15N20 carbon steels.

John Cammenga of White River Knife & Tool offers wood-handle fillet knives like this model (left) with a SM-100 blade and tiger-maple handle. Cammenga explains, “At the BLADE Show and SHOT Show, we introduced the world’s first fillet knife made with a blade of SM-100, a corrosion-proof alloy. This particular custom measures 63 HRC on the Rockwell hardness scale, features a 3/16-inch-thick spine and is still flexible! It is a ‘step-up design’ where the handle is notably higher than the cutting edge. The knife was designed by Steve Geelhoed, and while the original is not for sale, replicas sell at $750 each.”

“I used carbon steel on this because it holds an edge better than some of the stainless steels,” Kopp explains. “It does, however, require more care than stainless blades.”

The attractiveness of the damascus pattern is certainly inviting. “Yes, it’s kind of unique seeing a damascus blade on a fillet knife,” he admits. And what about function? “My brother used it on a fishing trip,” Kopp relates, “filleting 30 or so fish with it, and he was pleased with its performance. In fact, I think it outperformed an electric fillet knife!”

Maker of the Best Fillet Knife at the 2010 Professional Knifemakers Association Show, Todd Kopp chose a 7.5-inch damascus blade and sambar-stag handle for this particular model (left). Note the small details like how he carved the 416 stainless steel buttcap to match the natural grooves of the stag. The maker’s list price: $475. (Buddy Thomason photo)

Cammenga runs White River Knife & Tool, a family-owned business with a full array of fillet knives in its line. “A strong case can be made for many great alloys available today,” he says. “We chose 440C for our Limited Production and Custom Finished versions in 2013. This high-carbon, stain-resistant steel retains our hand-sharpened, leather-honed edge for a very long time. It also provides reasonable corrosion resistance.”

Cammenga uses wood handles on the fillet knives. “The wood is stabilized and will not shrink, swell, or absorb blood or oil,” he explains. “We also offer a cork handle with a wooden pommel. The cork handle with a 6- or 8-inch blade will float [if the knife is dropped in the water]. Also, our unique ‘step-up design’ helps to keep the handle [and knuckles] a little farther off the cutting area, a nice feature when filleting on less than ideal surfaces.”

Flexible On Flexibility

Cammenga says he thinks blade flexibility on fillet knives is largely a personal preference. “At the 2013 SHOT Show, we received some comments that our blades could be a little more flexible, and some that they could be less flexible,” he recalls. “Our current offering tends to be more rigid on the 11-inch blade, moderate on the 8- inch blade and more flexible on the 6-inch.

“That which makes a good knife makes a good fillet knife.”

Bird and trout knives certainly fit in the fillet knife family. Cross uses straight stainless steel on some of his knives, but adds a beautiful twist to others.

“Yes, actually I use both straight stainless and stainless damascus, depending on the customer,” Cross remarks. “With exposure to the water, the stainless aspect is important. As for stainless damascus, it looks a bit classier and there is a segment of sportsmen who appreciate a beautiful and functional knife to go with their Parker shotgun or Sage reel.”

Bird and trout knives have to pull double duty. How does damascus steel perform on the fishing half of that equation? “This knife works well for its appointed tasks,” he concludes. “But as with any short blade, there is not a great deal of flex. It is certainly possible to make the blade thin and flexible, though.”

Cross’s bird and trout knife employs bronze fittings. “Bronze is tough, and stain and corrosion resistant, especially to salt water. It is harder than brass, develops a nice, warm patina, and is easy to care for.” Function plus beauty: just the things knife lovers tend to value.

You make fillet knives do their work under tough conditions. But don’t suffer with low-quality knives. Craftsmen such as Wilson, Kopp, Cammenga and Cross have proven that you can combine function and form in beautiful fish knives.

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.