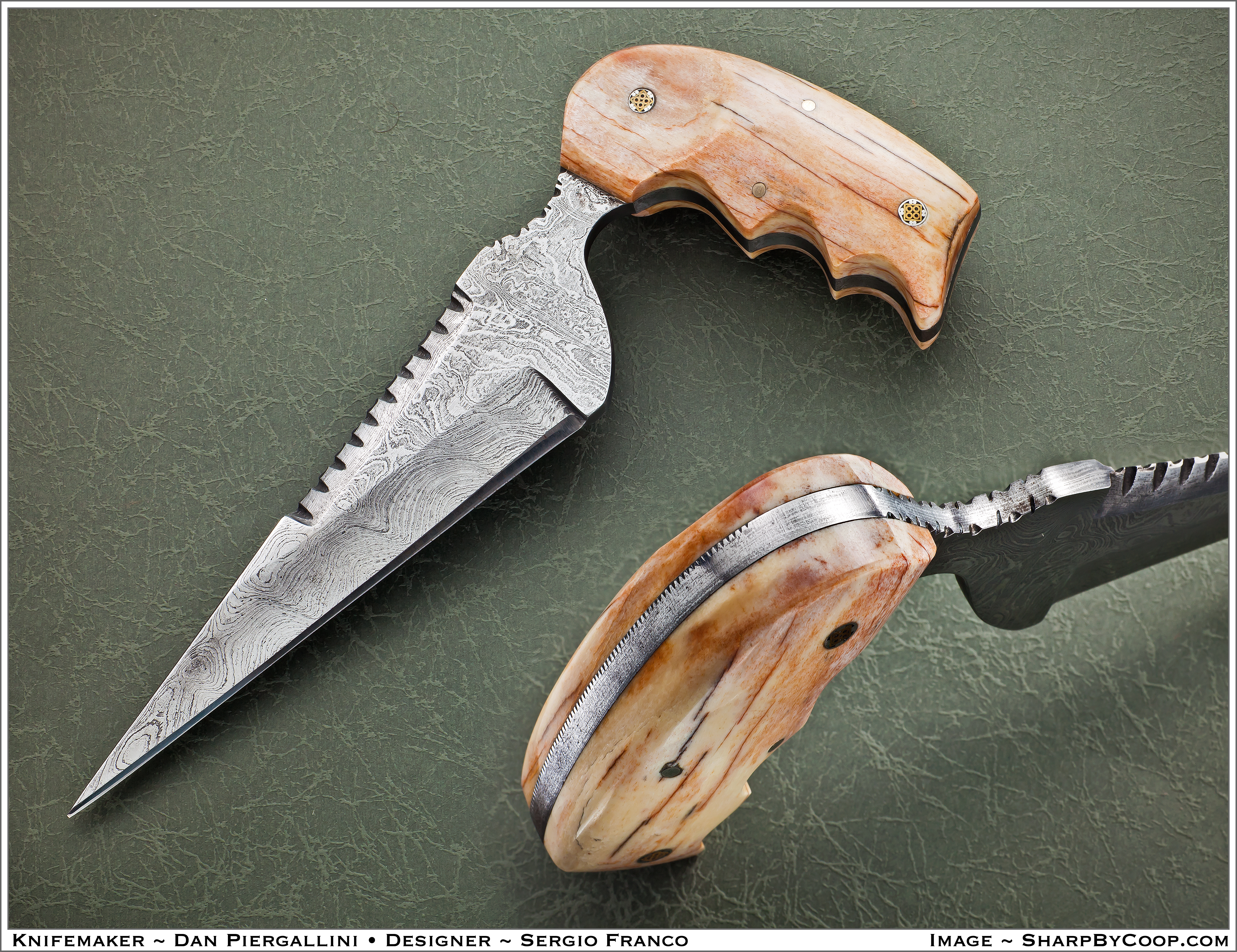

Sandy McClure of Giraffebone.com says giraffe bone remains hot because it is available, can be dyed several rich colors and can look like ancient ivory, as here on Dan Piergallini’s push dagger. (SharpByCoop.com photo)

Preference, use, and supply and demand help determine the most popular grip materials

by Stephen Garger

Getting a clear idea of what is hot in materials for knife handles can be difficult. Aside from obvious factors such as personal taste or intended use, there are considerations of supply and demand and national/international economics.

“Typically, in our business, whatever is ‘hottest’ has more than one answer,” observes Kristi Culpepper of Culpepper & Co. “People may be looking for what’s hardest to get and consider that material hot because of its rarity.” Shannon Edgington of Knife & Gun Finishing Supplies (K&G) has a similar take.

“Stabilized woods are hot and look great, with box elder burl the most successful dyeing wood,” she says. Aside from the woods, Edgington noted that water buffalo “is being jigged to look like impala and stag.” Meanwhile, giraffe bone continues to get heavy use as a handle material.

“It’s pretty hot because it’s available, and you can get it in natural dyed colors, and it can also look like ivory,” says Sandy McClure of Giraffebone.com, which deals primarily in African materials. “There is plenty of giraffe bone because lions are still killing giraffes through a [natural] culling process,” she notes.

A different perspective accompanies trends in synthetic handles. Chris Hartman, co-president of Masecraft Supply Co., says G10 laminates and canvas paper and linen Micarta® remain hot. “The materials are impact resistant, waterproof and highly suitable for individual makers and manufacturing without worry of warping, twisting, shrinking or cracking,” he notes. “In addition, the substances are readily available and cost effective, thus far better suited than natural materials for the high-tolerance needs of today’s manufacturers.” Mike Sheffield of Sheffield Knifemakers Supply shares Hartman’s assessment.

“Working/tactical knifemakers and manufacturers are buying Micartas and G10s because they are easier to machine, get in sheets and cut out handles,” he says. “Micarta and G10 also tend to hold up better than natural products.”

Hartman indicates the Masecraft line of paua, abalone and awabi shell and acrylic laminated veneer sheets is finally beginning to take off. “These are great new products as they look genuine, use a combination of actual shell and acrylic, and are less than a third of the cost of solid-shell-laminated sheets. It’s like working with acrylic with all the natural beauty of real shell,” he notes. “Two years ago we started to develop some of these materials. It always seems to take about two years from prototype to actually showing up on production knives.”

Sheffield says his company has been applying CNC machining to grips. “I’ve been making handles for a couple of manufacturers and producing an end product out of Micarta or G10 to their specifications,” he states. “I scan their template/design and produce a handle for them on a short-run basis.” For example, using a regular blank Sheffield has been selling for years, he can produce a pattern you would expect to see on bone, a process that accounts for the jigged-bone appearance seen on some Micarta and G10 handles.

According to Hartman, composites also have grown in popularity. “[The supply of composites is] steadier than that of natural products, and the materials themselves are more stable and cost effective for individual makers and manufacturers,” he says. “In addition, some of the best composite materials are made in the USA, and are far better suited for today’s high-tolerance manufacturing needs, with good durability.”

New Resources

The natural material side of the handle market is also dynamic, with suppliers always on the lookout for new and interesting resources.

“We currently have a supply of bison bone and jaws [dating back to] the Pleistocene Era that have been underground and exposed to ground minerals, so they have the coloring and look of mammoth ivory,” Culpepper reports. “We also have a stock of whale bone that should be coming into the custom market on some knives, some traditional jigged patterns in hot new colors for 2012 like Sunset and Bamboo, and several new jigged patterns.” She points out that a number of companies that specialize in tactical knives are updating their more traditional lines with limited-edition dyed and jigged bone, mother-of-pearl inlays and other natural materials. Meanwhile, Edgington says K&G’s resin wood shows promise for handles. “It has gone through a lot of testing and has been found to be similar to Micarta, and is used in various patterns for kitchen knives and cutting boards,” she notes.

Hartman says red carbon fiber did not make the cut. “It was simply too expensive to produce with not enough demand to support the cost,” he says. “We developed a new product which uses black carbon fiber with red G10 layering, creating a hybrid available in several colors including blue, yellow and soon a carbon fiber with a green layer.” The material has the advantage of being “about a third less expensive than the old red carbon fiber,” Hartman notes. Sheffield also has a material that is a red-and-black carbon fiber alternating with G10.

Scarcity and Shortages

I asked whether sambar stag, ironwood and mother-of-pearl remain scarce, and if there will be any shortages in other natural materials.

“Natural materials have such a demand all over the world that the U.S. is no longer first on the list when it comes to purchasing them,” Culpepper says. “Mother-of-pearl and stag both are commodities in China because of uses in all their industries, from furniture and jewelry [mother-of-pearl] to medicine [stag].” Hartman concurs, opining that eventually sambar stag and ironwood either will disappear or the price will become so outrageous that only a few will be able to afford them—though for now both are available in pretty good supply.

“Actually, I believe it will be the cost of bone, horn and exotic woods you will see continuously rise over the next several years,” Hartman notes. “Eventually, these supplies will be wiped out or the labor force that’s willing to cut and supply them will have moved on to better jobs. Sources of these products in China are already gone due to economics, and prices from India are on the rise with supplies decreasing.” Though these things are happening now, it is difficult to provide an accurate time frame in which the changes will be felt in a meaningful way.

“Business has been very slow related to the economy since knifemakers are not buying unless they’re selling something,” McClure observes. “They’re not stockpiling anything but are using what they have.” Sheffield notes there is a lot more competition and Edgington says she does not carry the stock as in years past. “We don’t want to come across as price gouging and will absorb a lot to keep the prices down for the customer,” she sighs, “but the price to us keeps going up on the nice stuff.” Hartman agrees, concluding on a positive note, “The knife and gun industries seems to be much more stable than other similar markets in this economy.”

For more on the latest knives, knife legislation, knifemaking instruction, knife trends, knifemakers, what knives to buy and where and much more, subscribe to BLADE® Magazine, the World’s No. 1 Knife Publication. For subscription information click on http://www.shopblade.com/product/blade-magazine-one-year-subscripti…?r+ssfb021112#BL1SU

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.

Click Here to Subscribe and get your free digital 2022 Knife Guide!