Thinking of dipping your toe into the exciting world of collecting custom knives? Read these tips first.

What for Look for in a Custom Knife

Don’t buy or collect trends. Buying what’s “hot” today may mean selling at a loss tomorrow. Buy a knife because you like it, not because you think it will increase in value. If the knife is well made, it will always have value.

Decide what the knife will be used for and choose accordingly. Is it pleasing to your eye? Hold it and see how it feels in your hand.

Is it easy to carry? Is the edge geometry correct and are the grind lines even? Are there gaps at joints between the blade and guard? On a folder is there too much blade play—up and down and/or side to side?

Does the knife walk and talk? What about fit and finish?

On a linerlock or framelock does the lock engage too late or too early? Is lockup tight? Feel the knife all over for hot spots and evaluate it in terms of quality construction and materials, creativity, etc.

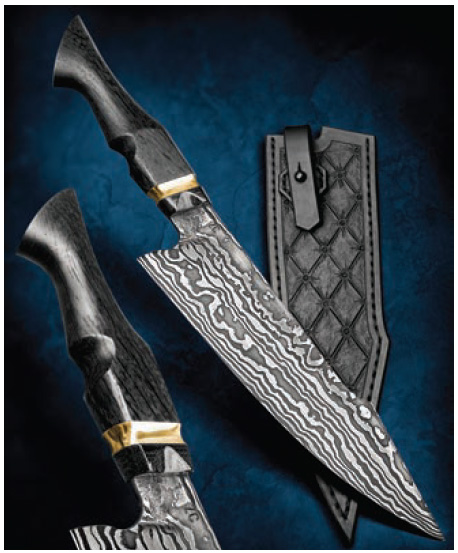

If the knife is a fixed blade, a sheath can add value. However, the knife needs a sheath only if it is important to you, though it may affect resale value. A good sheath can cost $75 to $150 to have one made, so this is a good benchmark of value detraction.

On the other hand, some sheaths can be distinctive works of art that can add significantly to the knife’s overall appeal and value.

Commissioning a Completely New Custom Knife

Be wary of custom orders, as many things can go wrong, including long wait times before delivery, and makers who shun lengthy dialogue over what might be a healthy monetary investment on your part. Moreover, the finished knife may not meet your expectations.

Custom orders may be best for makers early in their careers. Veteran makers may wind up making a custom order that doesn’t represent their style, so the knife may not increase in value.

Place an order with enough time to pick the knife up at a time that works for you, such as during BLADE Show.

Determining Price of a Custom Knife

expensive model. An art dagger by Dennis Friedly with engraving by Gil Rudolph would appear to qualify on most all of these counts. (SharpByCoop image)

Never be afraid to ask a maker, purveyor or any seller why a knife costs what it does. Ask him/her for some background and history on the knife, both of which can embellish a knife’s value, especially if the knife is a vintage one.

If you pay a high price for a knife, see if the maker has been in business for a number of years, has a strong following and that the knife is something special. Such a knife should be made of materials of a higher quality/more in demand than a less expensive model.

If the maker is just starting out, be sure his knives are priced reasonably.

If the knife appears to be underpriced, be sure there’s not a mistake in its construction.

For a guide, check the prices of like knives on the sites of purveyors who have been in the business for a long time. They wouldn’t still be in business if they didn’t offer reasonable pricing.

Are Deposits Necessary?

One purveyor said you should never pay an upfront deposit on a custom order. No exceptions. Watch out for makers who claim to need the deposit to buy materials, etc. You are not a finance company.

Besides, as one purveyor said, “It’s unfortunately very human that it’s hard to get work done that is already paid for.”

Warranties

Ask for a written guarantee regarding what the maker will and will not cover in terms of damage caused by use/abuse, flaws in workmanship or materials (excluding natural materials that chip and crack), etc.

The warranty should last for the remainder the maker’s career.

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.