The wakizashi may be the most sensible and useful Japanese sword. Between a katana and tanto in length, the “waki” is long enough for any number of heavy-duty jobs but also short enough to use in confined spaces. And, for those into collecting/displaying Japanese swords, the waki offers all the traditional accouterments of high-end pieces, too.

“The CAS Hanwei Tactical Wakizashi crosses over to the machete market to a large extent but still has the mystique of the traditional wakizashi, which a lot of people know about, so it’s a pretty good combination of a machete and an old-time weapon,” CAS Hanwei’s Barry Ross noted. “A lot of our customers use it as a brush-cutting sword. Those hiking in the backwoods carry one for cutting brush for paths and to make shelter, and [some other of our customers] use it as a defensive weapon.”

With a manufacturer’s suggested retail price of $209, it is a lot less expensive than traditional wakis that have more expensive fittings and cost much more to build, Ross added. Sporting a checkered Kraton handle for a sure grip in slippery conditions, the CAS Tactical Wakizashi has a 20-inch blade of 5160 carbon steel plasma coated for corrosion resistance.

For the plasma coat, CAS Hanwei has a process that applies a thin layer of nickel to the blade. It is a very tough coating that forms a physical bond with the steel, one Ross said will not wear off. “5160 will rust easily if left to its own devices and since these things will see a lot of work, we needed to do something for that”—thus the plasma coat, he reasoned. The weatherproofed, glass-filled-resin scabbard is equipped with a drain hole so it will not hold water.

THE G2 TEST

ABS master smith Wally Hayes offers tactical, traditional and high-end wakis. “I make tactical wakis for Larry Brahms of Bladeart.com,” Hayes said. “Brent Beshara tested one at the [Usual Suspect Network] G2 Show. We had to make something that was the biggest bang for the buck, something to take into battle and not cost an arm and a leg, so we came up with the tactical waki.” It has a 14-inch blade of 1084 carbon steel and an 8-inch handle with a Turk’s head knot and a ray-skin nylon wrap resin coated to waterproof it. Hayes indicated he has since switched to W2 tool steel for the blade because W2 produces “cooler temper lines and stays straight in the heat treat.” His list price: $1,200. He also offers the double-edge/double-temper-line Hayabusa that he lists for $1,800. It has a 15-inch blade and an 8-inch handle of black ray skin and purple silk.

While Hayes said his waki production is about half tactical/half traditional, which breaks things up and makes them more fun for him, he indicated he is learning more toward the more expensive models to “push his limits.”

“As I move up the food chain, so does the demand for my higher-end stuff, more engraving and gold,” etc., he said. “I’m attracting higher-end collectors” from such places as Cypress, Germany, China and Australia, to name a few. “And Axl [Axl Rose of Guns ‘n Roses fame] loves my stuff—traditional and tactical,” he added. “He’s got my wakis hanging in his kitchen.”

An example of Wally’s higher-end waki would include one with 1600 layers of three different carbon steels—1050, W2 and 15N20. “I put in some of Alfred Pendray‘s carburized electrolytic iron; that way I can get the brightness and tool up to between a thousand and 1600 layers,” Wally noted. All the handles are traditional. He carves and engraves them and embellishes them in gold and silver, depending on the price, which starts at $3,500.

BACKYARD CUTTERS

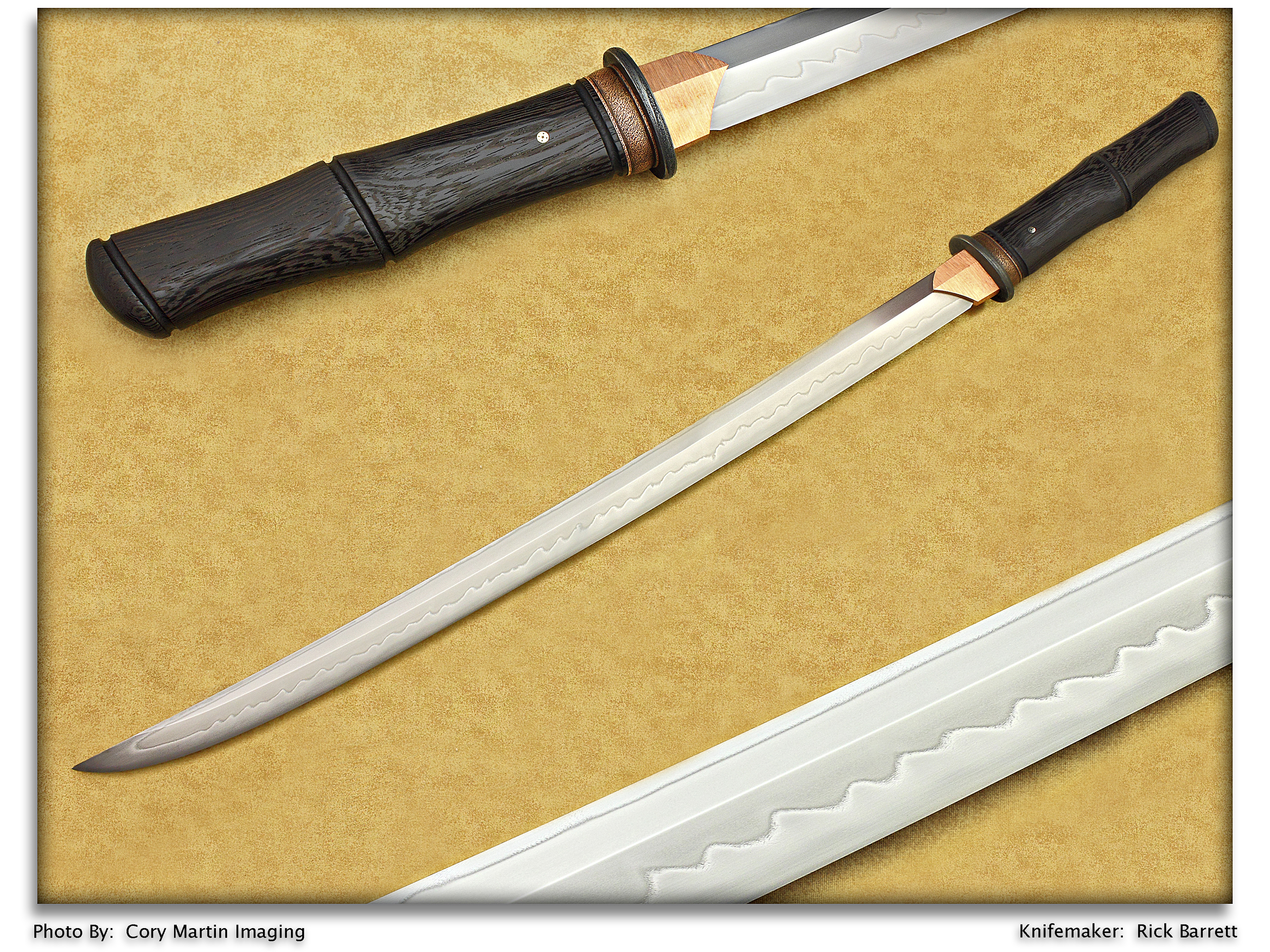

Rick Barrett, who also goes by the Japanese name of Toshi Hisa, said he prefers to make his wakis with semi-traditional-type blades. “I like the longer or oh wakizashi in the 23-to-25-inch blade range, so it’s almost a short katana,” he said. “It makes a great tactical blade; it’s not so long you can’t use it in confined spaces.” Rick uses 1075, W1 and W2, modern carbon steels heat treated traditionally for a hamon.

He indicated many of his customers include martial artists and “backyard cutters,” the latter whom cut rolled-up straw mats and bamboo in their backyards. “In my opinion, cutting things is similar to shooting firearms. You go out and practice to improve your technique; it is a bit of a hobby in itself,” he opined. “It’s like people who don’t shoot; they don’t know the pleasure people get hitting a target. Those who don’t cut don’t get it either, but [those who do] get a thrill from cutting targets.” Rick said he also has military customers who order anything from a long tanto to a short waki for use in Afghanistan as a backpack piece, as well as collectors who “just put the swords on the mantle.”

Rick sells most of his wakis—and swords in general—without handles. “I usually do the blade alone and let the customer decide if he wants the rest done traditionally or contemporary. That’s the way the Japanese makers do swords [without handles]. A lot of Westerners look at it as not finished, whereas the Japanese look at it as finished; the rest is ancillary. I get questions all the time: ‘When are you going to finish it?’ For years I would finish it and people would say they wanted something different. You can’t just change it easily. It requires redoing a lot of things. I spend $200 on getting the handle wrapped and if I have to rewrap, I will have to undo the handle, which costs $200, and rewrap, which is another $200.”

When he offers a waki with traditional mounts, he hands it over to a traditional mounter. “[Traditional mounters provide] a more accurate wrap than I could ever get,” he observed. “[Traditional mounting] takes years in itself to perfect. I don’t want to offer something sub-par for a sole-authorship piece. It is far better to have a tighter handle wrap, diamonds lined up perfectly, and so on. The contemporary handles I do all myself.”

3V WAKIS

Dan Keffeler makes tough, functional user wakis. He said he was invited to a dojo in 2004 and watched a participant’s sword bend during a cut. “He wound up taking it to a polisher to straighten the blade and the bill was $900,” Dan recalled. “I was working with CPM 3V and wondered why can’t I make a [sword] blade out of 3V? It has a lot of impact and chip resistance and though it’s not as tough as S7 it’s still tough, so I started making Japanese swords from 3V, testing, dialing in heat treat for a balance of all the properties we’re looking for, one that would not take a set [bend] and would chop through a 4×4.”

Since then Dan said 3V has developed a durable reputation for both knives and swords, including his wakis. “I am one of the first if not the first to use 3V for swords, and I hope my work with it over the last eight years has helped contribute to that,” he noted. “I think 3V has the best combination of toughness and edge retention for a sword blade of any steel I’ve tested. I compete in BladeSports International cutting competitions and hold the world record [1.21 seconds] for the fastest 2×4 cut, so I have spent a lot of time on what makes things cut.

“With a sword, toughness is primary; with a knife, edge retention is primary. For swords, I have not seen another steel that can put those two attributes together like 3V can. When heat treated properly, it’s semi-stainless like D2. You have to care for it but not like for steels like O1. 3V is abrasive resistant so it doesn’t scratch up like other sword steels. It’s harder to sharpen and grind but because it’s so tough and chip resistant, I can grind it to a thinner edge, and a thinner edge is easier to sharpen.”

For handles for his user pieces he uses a material called Tero-Tuf. “Brian Wagner and Jeff Crownover turned me onto it,” he said. “It’s synthetic like Micarta® or G-10 but is tougher than both. It’s laminated and has a resin like canvas Micarta to make it stronger.

“I was testing different glues on G-10, Micarta and Tero-Tuf and trying to break the glue and hitting the handle with a hammer. The G-10 would break and crumble in chunks. The Micarta took more hits but would shatter. The Tero-Tuf would throw the hammer back at me. It’s hard to get it to fracture.

“I sent a knife [with a Tero-Tuf handle] into Knifetest.com and [the tester] hit the handle with a sledgehammer 50 times and couldn’t break the scales. It’s really a high-impact material. Another benefit is it has a really good grip when wet.”

EQUAL PARTS HOT & COOL

Useful, traditional, contemporary and collectible, today’s wakizashis have everything going for them that enthusiasts look for in a Japanese sword. If buying such a sword is on your list, consider the wakizashi, especially one of those described herein. Equal parts hot and cool, wakis are hard to beat.—by Steve Shackleford

How Long The Waki Blade?

How long is the blade of a wakizashi? According to Rick Barrett, since the waki is more of a short carry sword, the blade normally is in the 14-to-22-inch range. As for the oh wakizashi—translated as long wakizashi—he said the range is 23 to 25 inches.

Barry Ross put the waki blade-length range at 18 to 21 inches. Dan Keffeler said waki blades generally span from 16 to 24 inches. His assessment gibes with the description by the late Bob Engnath in his “Basic Blade Shapes of Ancient Japan.” After 25 inches, Keffeler noted, the blade falls into the short katana range, with the standard katana blade at least 27 to 28 inches long.

According to information supplied by swordsmith David Goldberg, a wakizashi is “a medium-sized blade over one shaku but less than two shaku in length.” Wikipedia indicates the Japanese shaku has been defined to equal 11.93 inches. Two shaku equal 23.86 inches.—by Steve Shackleford

For more on the latest knives, knife legislation, knifemaking instruction, knife trends, knifemakers, what knives to buy and where and much more, subscribe to BLADE® Magazine, the World’s No. 1 Knife Publication. Click on http://www.shopblade.com/blade-magazine-one-year-subscription-us/?r+ssfb072512 for more information.

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.

Click Here to Subscribe and get your free digital 2022 Knife Guide!