Written by Dexter Ewing

Breaching tools are handy to have if you’re a firefighter, an EMT or in law enforcement. They can assist in gaining access to structures or vehicles in an emergency to help extract an accident victim, or to forcibly gain entry into a house or apartment to apprehend “the bad guys.”

There are differing varieties of breaching tools. Those in the story are tomahawk-based; they’re like standard tomahawks, but incorporate other features that make them more useful in emergency situations. Think tomahawks on steroids!

CRASH BROTHER

U.S. military veterans Jared Ogden and Grady Powell designed the Camillus CRASH breaching tool. Ogden served as a Navy SEAL and Powell as an Army Green Beret. Both have designed other knives and tools for Camillus, employing the expertise they gained from their years of service to create efficient tactical implements. One such design is the CRASH breaching tool.

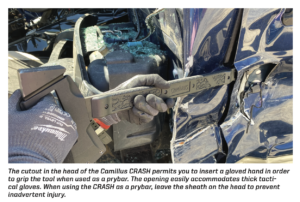

At 21.75 inches overall, the CRASH features 3Cr13 stainless steel with a titanium-nitride coating for rust resistance. The cutting edge is 3.5 inches, long enough to be used effectively as an axe or tomahawk. A generous-sized cutout in the head allows for control and leverage when using the prybar/metal- cutting claw feature on the end of the tool.

A checkered-face hammering surface that measures about 1 inch wide by 2.3 inches long is on the head’s opposite end. The checkered face provides grip and won’t slip off the surface you’re hammering. The handle scales are molded Zytel for solid purchase. Molded-in texturing further enhances gripping ability. On the hawk side of the handle, two sets of machined- in finger grooves enable your fingers to settle in for a better grip.

Weighing 6 pounds, the CRASH can develop some serious momentum when swung as a tomahawk or hammer. In addition, the extra length and weight of the hammerhead make the CRASH a very effective axe. Moreover, the long handle allows for added leverage.

I hacked up and disassembled one wood pallet with the CRASH. It’s a powerful chopper and the edge bit into the wood aggressively. Using the hammer portion, I was able to knock the boards loose. It’s very convenient to have the two tools in one product for such a task.

Conversely, I dislike the prybar portion. Understand that the prybar isn’t the standard wedge-shaped tip found on so many commercially available models. The wedge tip allows for easy insertion under materials to initiate prying. However, while dismantling the pallet, I found myself wanting the traditional prybar wedge tip. Why? Because it would make the job easier to have three convenient tools in one rather than two. In fact, I found the prybar useless. It’s great to make use of the additional length of the tool, coupled with the integral handle grip in the head, but the C-shaped prybar tip wasn’t effective at all in getting in between the pallet boards.

AUTO SALVAGE SHAKEDOWN: I took the CRASH to a local auto salvage yard to test the axe head. After just a few swings, I drove the head into the door of a large pickup truck. Though the edge suffered some rolling, it wasn’t a big deal. When I tried to hack into the door of a second vehicle, about a quarter inch of the head’s edge broke off. Yes, it made it into the door but the CRASH was damaged. Nonetheless, the coating held up well, and, overall, the CRASH looked no worse for wear.

COMPACT HAMMER/PICK

Halfbreed Blades builds some of the most robust factory fixed blades and folders Down Under. It also has a line of rescue tools to augment its knife line. One such model is the IRT-01 (Incident Response Tool).

At a tad over 10 inches overall, it is one of the more compact of the test breaching tools. However, there’s a reason for its compact nature: It’s designed to carry via insertion into a single column row in a MOLLE plate. Neither a sheath nor a holster is included. At .32 inch thick, the IRT-01 can get the job done.

Steel is Bohler K110—basically, D2 tool steel. D2 is widely known for high impact resistance and toughness, as well as ease of working and resharpening. The tool is available in two colors of Teflon coating—black and flat dark earth (FDE). The entire length of the handle has a series of traction grooves machined into the flats, and there are traction notches on the handle edges. The two features work in conjunction for a secure, nonslip grip, even while wearing gloves.

A hammer and modified pick are on opposite ends of the head. The hammerhead is a bit over 1.5 inches wide and shares the same thickness as the handle—a generous .32 inch. There’s enough face to use it as a field- expedient hammer. On the opposite end is a modified pick with a rounded blunt end, which can be used as a glass breaker. The handle traction notches continue up under the pick so you can employ the “break-and-rake’’ method of glass breaking: After breaking the glass, the tool is used to rake and pull the glass shards out of a window frame.

Handle weight is optimized via the skeletonized design. It includes a built- in, multi-sized wrench for tightening nuts and bolts, as well as a quarter-inch drive hole that accommodates common hex bits. At the very end of the handle is a prybar/nail-puller. The single beveled side of the prybar allows for easy insertion between a wooden door and door jamb for forced entry/exit.

I was able to dismantle pallets with the IRT-01. I used my 32-ounce dead-blow hammer to pound the prybar end of the tool under the boards. I then grabbed the hammerhead and pulled to separate the boards. I also used the nail-puller to extract nails.

The tool has zero flex. You can whale on it as hard as you want without fear of bending it. Its short length might be a bit of a hindrance in tasks where leverage wins out.

AUTO SALVAGE SHAKEDOWN: I used the IRT-01 as a window breaker at the auto salvage yard. However, you can’t hit a window head on with the pick end. You have to catch the glass on the corner of the pick where there’s a point of contact on the window. I hit it in the lower corner of the window and, with one good, stinging pop, the glass shattered completely. I then used the underside of the pick to rake away the broken glass and knock away any that was still hanging on as if I were clearing the window out in order to gain access into a vehicle to rescue the occupants. Unfortunately, due to the IRT-01’s short length and lack of a cutting edge, that was the end of the salvage-yard test.

HACK ATTACK

DoubleStar’s Wrath crash hawk combines the best of a tomahawk and breaching tool all in one. Starting with .275-inch- thick 80CrV2 carbon steel, the 16.5-inch Wrath features a multifaceted face that simultaneously cuts as it penetrates. A scalloped spike on the opposite end penetrates wood and metal. The handle has a heavily checkered, machined-in texturing that bites comfortably, even when you’re wearing gloves.

The test version of the Wrath DoubleStar provided is a sample of the new model, which will be sold on the company’s website and not by dealers. It has a Parkerized coating as opposed to tan Cerakote®, and a green-and-black G-10 handle instead of the standard tan and black. Other than the cosmetic changes, the Wrath is similar to the original design. Each model comes with a heavy-duty, eighth-inch-thick Kydex sheath.

The quality is definitely there. All the grinds are even and the cutting edges are quite sharp. In fact, everything about the Wrath fits up well. Hacking up a pallet is just pure fun! Because of the V-shaped hatchet head, the cutting edges attack at an angle relative to the wood with each blow. It really made the wood chips fly.

The Wrath has an aggressive bite. It managed to hack through about half the width of the pallet boards. At about the halfway point, it broke the rest of the way through via sheer blunt force. The handle machining worked very well for the task. I wore latex-coated, cut-proof gloves during the test. The aggressive, checkered machining pattern on the G-10 worked efficiently to keep the tool from slipping from my grip during the powerful chopping blows.

If you use the Wrath without gloves on, you’ll probably find the machining pattern too aggressive. My recommendation: Always wear gloves while using this tool. Once you do, you’ll realize it makes sense. There were absolutely no issues with hand slippage.

AUTO SALVAGE SHAKEDOWN:

During my auto salvage yard visit, I was able to hack into a vehicle door but there was a bit of a price to pay: The tip of the hatchet head broke off. Nonetheless, the rest of the head escaped unscathed. The 80CrV2 steel is tough! When I got home, I used a regular metal file to touch up the edges and make it more serviceable.

Author’s note: Thanks to the good folks at Lewisville Motor Co., Inc., in Winston- Salem, North Carolina, for allowing me to test the breaching tools on vehicles destined for the crusher. An auto salvage yard specializing in parts for late-model cars and trucks, the company serves the Piedmont Triad metro area of North Carolina—and beyond—with fast and friendly personalized service. Visit lewisvillemotorcompany.com or e-mail sales@lewmoco.com.

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.