Harking back to American military glory and post-war prosperity, antique switchblades from the 1940s and 1950 have enduring appeal.

From its first patent in 1884, the switchblade was an important addition to most early U.S. cutlery companies.

According to Mark Erickson, author of Antique American Switchblades, between 35-to-40 companies made and/or sold switchblades, including almost all of whose names long-time collectors recognize: Aerial, Camillus, Case, Challenge, Colonial, George Schrade, KA-BAR, L.L. Bean, Novel Shapleigh Hardware, Queen, Remington, Schrade Cutlery Co., Utica, Wade and Butcher, and Shapleigh Hardware, to list a few.

Because of the collectibility of the named companies and the significant variety of styles, sizes and handle materials associated with them, switchblades have become a serious endeavor for many collectors of antique knives.

Invention Of The Switchblade

As a serious cutlery collector, my downfall has been fingernails that bend backward with even the smoothest opening blades. The switchblade innovators had fingernails in mind when they produced a knife that could be opened without using a nail. In fact, some of the best switchblades are found in women’s old sewing baskets.

In fact, early switchblade ads tout the folder’s ability to be used by people with weak fingernails. “These knives will be a wonder for those who have difficulty opening a traditional knife” stated one such ad.

For many other occupations, the switchblade and its ability to be opened with one hand has proven immensely important. Mechanics, fishermen, ranchers, soldiers, veterinarians and even Boy Scouts were frequent users of the pocketknives. With a wiggling fish in one hand, it is easy to see how a switchblade could be a valuable asset to most fishermen when cutting a line.

Moreover, most switchblades have a lock/safety that keeps the blade from opening accidentally and the open blade from closing on the hand. An early Flylock Knife Co. ad touted, “The ideal knife for all outdoors and sports use. One hand only required to open or close, leaving the other hand free to grip a rod or gun.”

World War II Switchblades

World War II brought with it the necessity of supporting soldiers who parachuted behind enemy lines. Switchblades procured for the U.S. military were designed to cut the parachute suspension lines that became entangled during landing. The knives were carried in what has been described as “neck pockets’ in jump uniforms.

There are continuing discussions about the knives specifically made for and used by the U.S. military during the war. The discussions center around whether switchblades issued to troops all had jigged bone handles or jigged metal sides. Another discussion is whether all switchblades used by paratroopers had a bail—known in the military as a “lanyard staple”—or whether knives without bails also were used.

Units that used the knives included paratroopers in the 82nd Airborne and 101st Airborne Divisions, which included the 505th, 507th and 508th parachute infantry regiments. The 505th Infantry Regiment website shows switchblades made by Schrade Cutlery Co. stamped “Presto” with jigged bone handles and metal handles made to look like jigged bone painted black. Knives both with and without bails are included in the photographs. Switchblades made for World War II paratroopers also include those stamped Schrade-Walden and Schrade Cut. Co.

The book, 4 Stars of Valor: The History of the 505th Parachute Infantry, describes the equipment carried by paratroopers. In addition to main and reserve chutes, full uniform and helmet, the paratroopers carried over 70 pounds of equipment, including an M-1 carbine with ammo, Mae West life jacket, switchblade, water-filled canteen, trench knife, fragmentation and smoke grenades, mess kits, three days of K rations, escape map and compass, gas masks, toiletry items, 30 feet of rope, blanket, half a shelter and first-aid kit.

Post-War Military Switchblades

After World War II, several companies made switchblades for military personnel. According to one website, the first such knife was produced for the armed forces by Schrade Cutlery Co., designated as MC-1, an airman’s paratrooper knife, in 1957. Sometimes the knives are referred to as aircrew survival knives.

The first contract was awarded to Schrade Cutlery followed by a second contract to Camillus, and a third to Logan-Smyth. The orange-handle switchblades had two blades: one a master spear pattern opened by depressing the button, and a second blade shaped like a hook to cut parachute suspension lines. In my estimation, the hooked blade is not sharp enough to easily cut parachute lines and must be resharpened.

Civilian Switchblades

The early 1950s brought a renewed interest in cheap, colorful switchblades, with thousands of knives made by Imperial in its Jack-O-Matic Texas toothpick model, and Colonial, which used the Shur-Sharp stamp on its colorful models. The fishtail jackknives and the Texas toothpick styles were by far the favorite examples produced by the two companies.

The George Schrade Knife Co. continued to produce popular switchblades with celluloid handles stamped Presto. The knives were made with a single blade, double blades (the latter with a push button for each blade) and even a letter opener with a push button in one end.

Celluloid Handles On Antique Switchblades: Why?

The handle material for most of the inexpensive switchblades was celluloid. Thin sheets of the versatile plastic-like substance were molded around the knife’s metal sides. The most popular celluloid style was candy stripe. The knives also can be found in a wide variety of swirled celluloid handles in a myriad of different color combos, some with such recognizable celluloids as cracked ice and imitation tortoise.

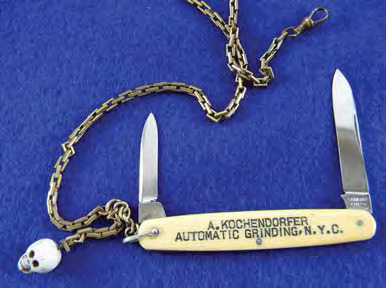

Because the knives were inexpensively priced, they were extremely popular with boys in the 1950s. Because of the knives’ widespread use, some advertisers saw an opportunity to emboss various ads on them, giving them away as a novel company promotion gimmick.

Allure Of Antique Switchblades

Because of their connection with the heroic actions of airborne troops during World War II, antique switchblades have continued to be a popular cutlery collecting niche. Moreover, since almost three dozen companies, each producing a vast array of sizes and handle materials, made the knives, the collecting field is wide open.

Even in the 1950s cheap construction, made more evident by the continuous opening and closing of the blades, the knives remain popular collectibles. No doubt one reason for the popularity is that antique switchblades remind many of the Golden Age of the 1950s and ’60s when kids played outside all day, shot their BB guns, and hit the corner gas station for a cold soda and a candy bar.

Ah, those were the days!

More On Switchblades:

- Why Are Switchblades Illegal?

- Out-The-Side Automatic Knives that are Stylish & Functional

- Stiletto Switchblade: Sharp And Controversial

- 4 Must-Have Automatic Knives