Summer school never looked so good with the 10th Annual BLADE University.

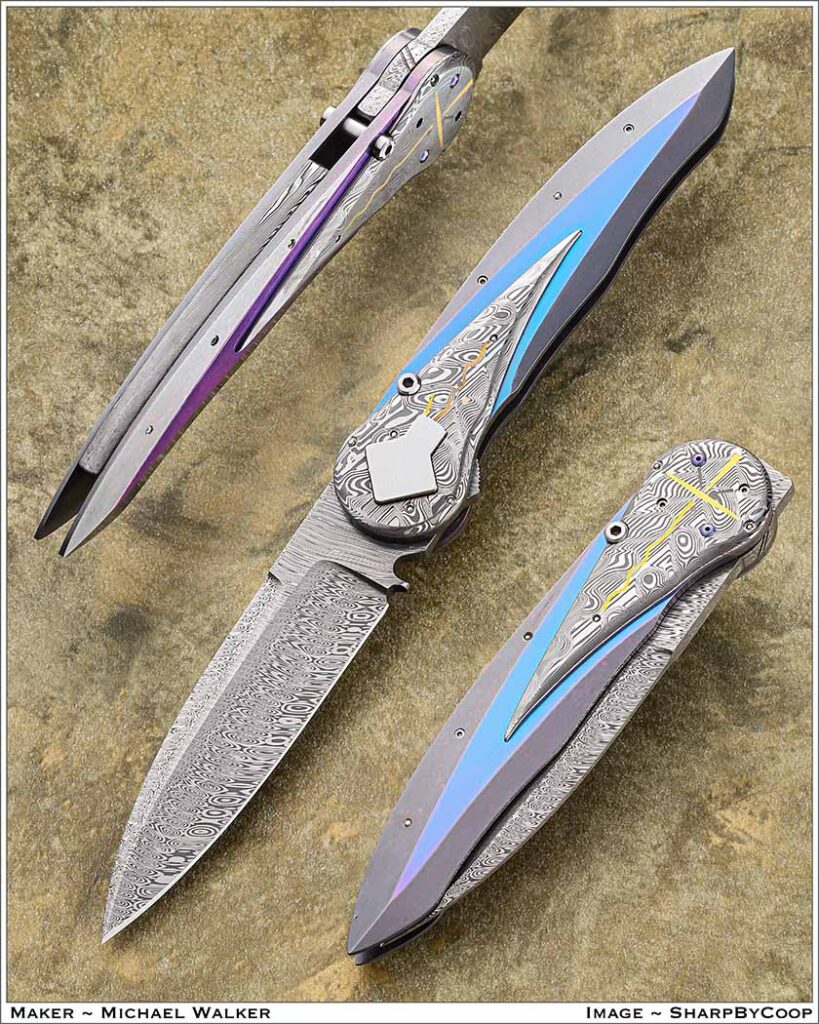

Cutlery classes taught by Michael Walker, the inventor of the linerlock, Bob Kramer, world-class maker of chef’s knives, and father-and-son damascus wizards Devin and Larrin Thomas are among the highlights of a full slate of knifemaking instruction for the 10th Annual BLADE University.

Sponsored by Work Sharp, BLADE University will be held in conjunction with the 42nd Annual BLADE Show June 2-4 at the Cobb Galleria Centre. Classes begin Friday, June 2, and conclude Saturday, June 3.

While most classes are held in the Cobb Galleria, some also are conducted under the tent in The Courtyard, aka the parking lot of the show’s host hotel, the Renaissance Atlanta Waverly.

BLADE University gathers some of the world’s best knifemakers, bladesmiths and other cutlery professionals to teach a wide range of subjects for the knife aficionado and novice alike. If you love knives, BLADE University has a related topic that will interest you.

Get Your Blade Show Tickets Now!

BLADE University Friday

8-9:30 a.m. Fundamentals of Grinding, The Courtyard. AmeriBrade and guest makers provide a general overview on grinds, technique and different equipment. The class is interactive and the AmeriBrade team answers questions and demonstrates suggestions for common grinding issues.

10-11 a.m. Exploring the Performance of Pattern-Welded Steel, Room 103. How does damascus perform? What are the best steel combinations for high-performance damascus? Is there really a “damascus cutting effect”? Learn about the experiments Devin and Larrin Thomas have performed on the strength, toughness and edge retention of damascus steel.

10:30 a.m.-12 p.m. Designing Kitchen Knives, Room 104. ABS master smith Bob Kramer reviews some of the considerations to ponder when designing kitchen knives. He explains the path he took to make household cutlery and why he made the choices he did.

1-2 p.m. CRKT Presents Q&A with Michael Walker, Room 104. BLADE Magazine Cutlery Hall-Of-Fame® member Michael Walker answers questions regarding the linerlock he developed in 1981 that revolutionized folding knives. He also discusses the evolution of the many other locking systems he designed post-linerlock, how to secure a patent, and his process for fine-tuning details on his knives. Questions are determined in advance, though Michael entertains limited questions from those attending as well.

1:30-2:30 p.m. Dancing with the Devil: Algorithms, SEO and Ecommerce, Room 103. Ben Petersen, co-founder of Knafs, a “goofy brand of knife-related products and ideas,” explains how to sell knives online and build your brand while navigating Google, Amazon and Meta.

2-3 p.m. What’s Hot in Knife Steels, Room 103. The heart of the knife is the blade steel, and few know steels like those who produce and sell them for a living. Three among the leaders in the field are Mike Norris Damascus, Nichols Damascus and Vegas Forge Damascus. Join representatives from each company as they discuss today’s hottest steels and what makes the steels so much in demand. They explore each steel’s performance, ease of sharpening, looks, other desirable traits and more.

3-4 p.m. Forging Ancient Materials and Why It’s Important Today, Room 107. Hosted by award-winning knifemaker Ilya Alekseyev, the panel explores how and why practicing forging methods used by the craftsmen of old translates into modern materials, and why it is important to establish proper forging techniques with such materials.

3:30-4:30 p.m. Hands-On Knife Sharpening, Room 113. Bring your knife or a borrowed one and learn the progression of shaping a bevel, sharpening and edge maintenance from the team at Work Sharp. You get hands-on practice and experience sharpening blades using a variety of sharpeners and abrasives, from whetstones to belts.

4:30-5:30 p.m. Unlearning Bad Habits: My Unique Path to JS, Room 107. Matt Stagmer focuses on knifemakers that have been in the craft for many years and how the path to becoming an ABS journeyman smith differs from someone learning those standards from day one. Included are tips and tricks to retrain your hands and mind.

BLADE University Saturday

8:30-9:30 a.m. Decorative Custom Knife Filework, Room 113. Knifemaker Kyle Daily of KHDaily Knives shows you his preferred files and the equipment he uses to make his five most popular filework patterns. The class outlines how to lay out your pattern and takes you step-by-step to being successful. Kyle does a hands-on demo and fields more-detailed questions at the end.

8:45-9:45 a.m. How To Forge a Hunting Knife, The Courtyard. ABS master smith Timothy Potier demonstrates how to forge a full-tang drop-point hunter. Using his propane forge, Timothy goes through the entire process, including forging the blade to shape from tool steel. He also discusses heat treating, normalizing and more.

9:30-11 a.m. How To Run a Successful Knifemaking Business, Room 104. ABS master smith Bob Kramer shares his 35 years of experience running a successful knifemaking business and tips to employ along the way.

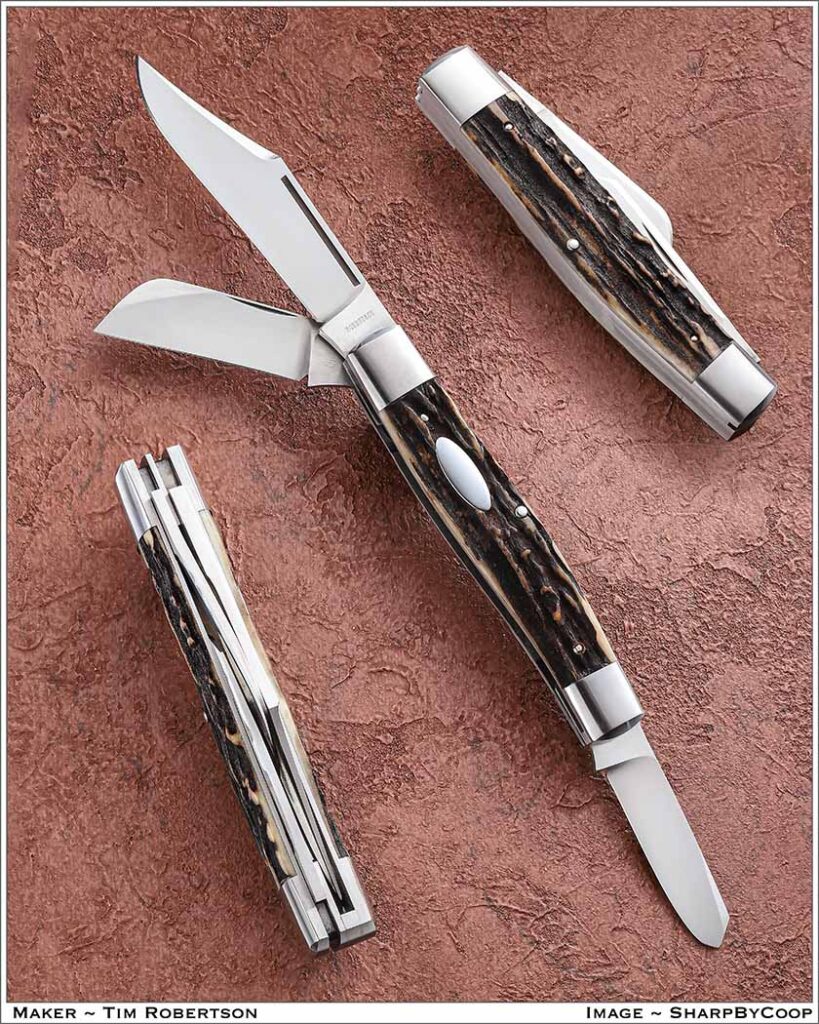

9:45-10:45 a.m. Reproducing Traditional Pocketknives, Room 107. Tim Robertson covers patterning traditional slipjoints from original factory knives in detail, including methods of disassembly, correct scribing techniques and proper hole layout (including changing the hole diameter). He also covers methods of using paper patterns commonly found on the Internet.

11 a.m.-12 p.m. 3D Printing for Canister Patterns, Room 113. Learn how to leverage 3D printer technology to make mind-blowing canister damascus patterns. ABS master smith Steve Schwarzer and Ron Hardman show you how to use this game-changing advancement to forge patterns on a budget that were previously unthinkable.

2-3 p.m. Let the Pros Critique Your Knife, Room 104. A panel of top cutlery craftsmen share decades of knowledge and experience in critiquing your custom knife. Award-winning makers Lucas Burnley and Luke Swenson, ABS master smiths David Lisch and Mike Quesenberry, and damascus-forging pioneer Devin Thomas examine your knife and tell you what’s good about it, what’s not and how you can make it better. Bring one knife only. Questions from attendees will be entertained throughout.

2:15-3:15 p.m. Hands-On Knife Sharpening, Room 113. Bring your knife or a borrowed one and learn the progression of shaping a bevel, sharpening and edge maintenance from the team at Work Sharp. You get hands-on practice and experience sharpening blades using a variety of sharpeners and abrasives, from whetstones to belts.

2:30-3:30 p.m. Writing for a Knife Publication, Room 107. Author/knifemaker Jason Fry and a panel of industry insiders share the tips and tricks it takes to get into the knife writing industry. Topics include idea submission and topic selection, interviews and content generation, methods for obtaining quality pictures and more.

4-5 p.m. Folder Design, Room 104. David Carver of Carver Knife Company teaches techniques on making a folding knife that works well, looks good and feels great in the hand/pocket.

Read More About The Blade Show:

- 2022 BLADE Show Knife-Of-The-Year® Award Winners

- 2022 Blade Show Custom Knife Award Winners

- BLADE Show West 2022: A Salt Lake Surprise

- 2023 BLADE Show Texas Factory And Custom Award Winners

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.