There’s something primal about a bone handle knife. We break down this eye-catching natural material, show what to look for and give you some top picks.

Bone has been around as a handle material just about as long as we have. It is safe to say that ancient cultures across the world have used bone as a handle material for as many as 100,000 years. Perhaps longer. Nobody knows for certain because these materials don’t last forever, even if perfectly preserved.

Bone Handle Knives History

Antler and bone have been used across the world and by virtually all peoples. We see, however, a distinct trend around 12,000 to 10,000 BC where they became the choice handle material for stone or volcanic glass blades. These handles were often carved to allow the instillation of replacement blades, given the brittle nature of the material.

These types of blades were state-of-the-art technology for millennia, with their traditional means of construction still in common use with many cultures at the time Europeans began exploring the world. The stone blades were extremely sharp and could last for months or even years if properly maintained.

Ancient people were experts at shaping these stone blades, and they could do so with great precision. Many of them were not small either, some stone spear points rival modern Bowie’s in length. The strength of these knives is largely dependent on the skill of the craftsman, and some of these blades and their handles still exist today.

Fast forward to the early modern era around 500-1000 years ago, we see that bone is purely a decorative choice on most knives. While functional, there is more of a challenge to working with it than there is wood. Wood in most cases is easily shaped while bone is a much more finicky medium. Bone is substantially more brittle, and it is harder to seal and finish. While it may seem like a durable material, it is quite porous and can shatter if struck.

In a way, bone went from being the material of choice to the choice of those who perhaps wanted to show off. Today this is the same story. It is hard to find individuals who carry around knives with ancient mammoth ivory grips, but they do exist. Will that same individual use that knife for camp work like ancient man? Again maybe, but not likely at the cost of that material.

Common Types Of Bone Used In Handles

Bone

For the most part, bone handles were typically made from whatever animal was available in the region. In ancient times, this could be any type of bone that was easily hollowed out or shaped. The femur bone (thigh bone) was quite common. Equally popular were the bones of the arm, and even the jawbone, depending on the animal.

Antler

Antler is and always has been a better alternative than skeletal bone. Antlers grow on members of the deer family only, from the skull and are semi-vascular. This means they have blood flow and skin while they grow. What makes them appealing then and now are they are shed by the animals yearly. This makes them easier to source, not requiring a kill to obtain. Furthermore, antler is extremely strong and dense, much more so than skeletal bone. In turn, it is less prone to shatter and is substantially less porous, meaning it is easier to finish and maintain.

Ivory

Ivory is another material that falls into the bone category. Elephant ivory has been strictly regulated for years. As a result, the material is exceedingly rare and possession of an unaccounted-for sample can land you in trouble. The ivory trade has been bad for the elephant population worldwide, but the animals are largely out of danger now, though this has not lessened ivory restrictions. It is a semi-grainless material that is not only strong but also easily shaped—lending to its popularity.

Mammoth Tusk

While there are regional laws pertaining to mammoth tusk— California, New Jersey, and New York you can’t transfer it—this ancient material is generally legal to sell and possess. (Always check your local laws to make sure this holds true for you.) Given restrictions on ivory, this material has become more common in recent year, sparking a rush to collect it on the Siberian tundra. The permafrost makes it so that these tusks are almost like new. Working with it is no more challenging than working with modern ivory, given the state of preservation is usually excellent. Other ancient materials that are suitable for use on knives include the tusks of walruses and narwhals, but these too are regulated in some states.

Most Desirable Bone Handle Knives

Beauty is truly in the eye of the beholder. While bone handles are certainly attractive, they are not always the best choice for daily use.

The main reason, aside from antlers, most bone material gets very expensive very quickly. Mammoth ivory can run well into the thousands of dollars for enough to make a couple of handles. For this reason, you typically see it as thinner scales as opposed to a full carved grip. If you go that latter route, the finished knife cost can skyrocket into the thousands, perhaps even over $10,000 on a nicely executed custom knife.

Pros And Cons Of Bone Handles

In the world of Micarta and G10 there is little advantage in bone or antler, particularly in durability and longevity. Like any naturally occurring material, there is the presence of unseen flaws that may become liabilities during use. These materials aren’t weatherproof in a true sense and can take on moisture and pull in oils. The mineral structure is different on each bone or antler and as a result, there is no true gauge for strength across the board. The ergonomics are also a challenge as most of these bones and antlers are shaped in a preexisting manner by the animal they came from.

This is not to say that they are useless, rather it is a matter of personal preference. Some people truly prefer how these materials look and feel and that is their right. That does come with accepting that they may be restricted to certain uses as opposed to other handle materials. For instance, hard chopping work and batoning are difficult on handles due to flex and vibration, and bone or antler may simply crack at the pins if a strike is not performed perfectly. The nature of these materials is sentimental, not just to the individual but to mankind as a whole being that they have been with us since the beginning.

Top Bone Handle Knives

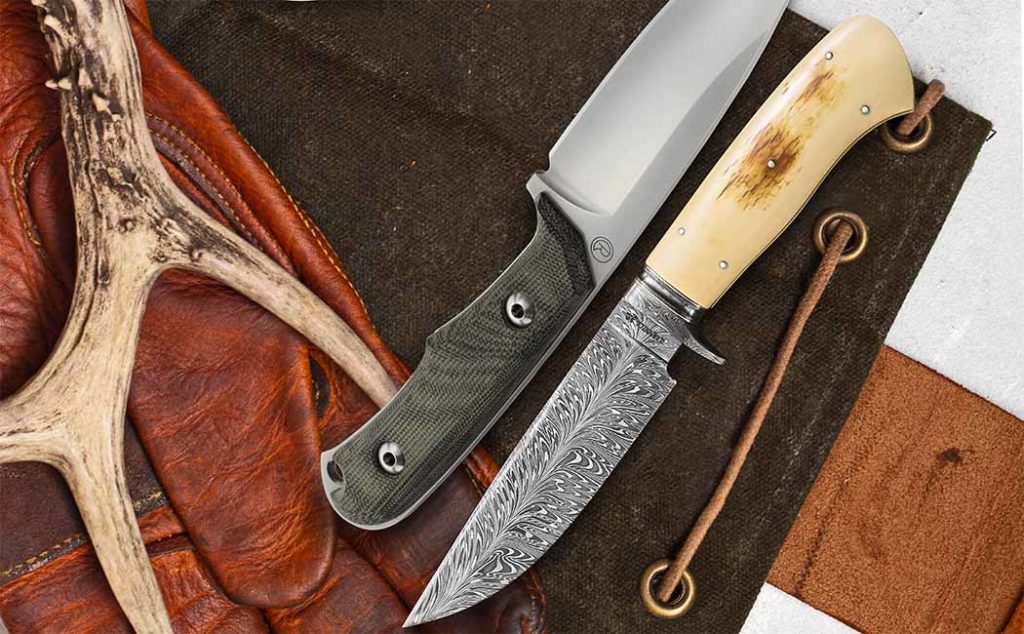

Wess Barnhil Gentleman’s Hunter

A custom offering by Wess Barnhill, the Gentleman’s Hunter was featured in the November 2022 print issue of Blade alongside some other fantastic bone or antler-handled knives. Modestly priced for a Damascus steel blade, Barnhill’s knife displays an excellent profile and layout for real-world use but is so damn beautiful you’ll probably want to keep it safe from blood and guts! Barnhill’s portfolio features several knives with natural material handles, each a work of art.

MSRP: $1400

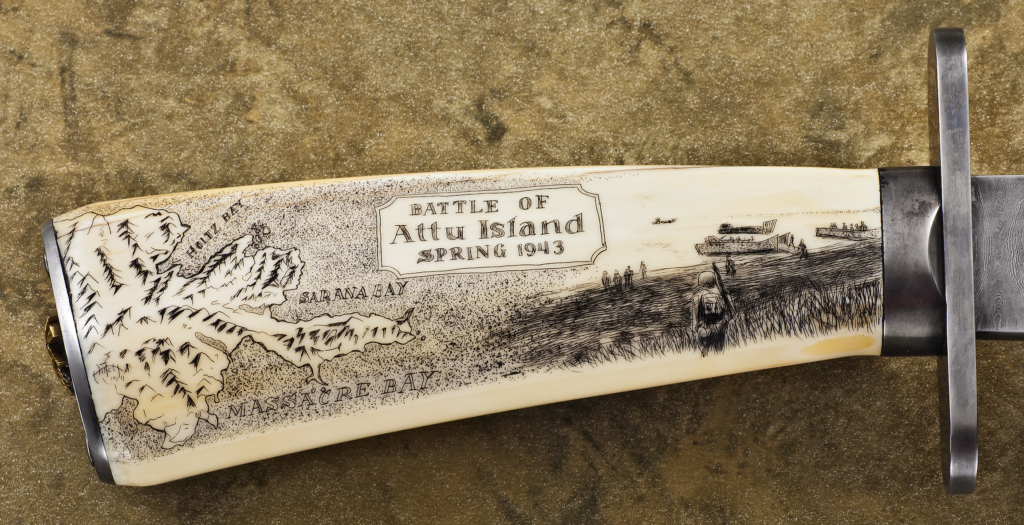

Mark Fleming Forged Southwest Trail Bowie

This knife was featured in the December 2022 print edition of Blade Magazine. Mark Fleming is an ABS journeyman smith, but his work looks exceedingly masterful at this point in his career. While this particular knife is custom, a similar piece will run you about $1,900, which is quite reasonable for such a complex execution. The knife as featured included an awesome-looking ancient walrus ivory grip, itself a relic.The grip material was salvaged from a native fire spindle that was used to start friction fires. Interestingly, you probably could still use this in that manner and you wouldn’t be outside the times. Grip indentations for starting friction fires are common on many knives today.

MSRP: $1,900 (for a similar design)

Rapid River Knifeworks Kodiak

Rapid River Knifeworks offers a tremendous number of custom services and a wide range of knife products. Located in Michigan’s upper peninsula, the company has excelled in adding traditional flair to its lineup and the products stand out from others across the board. The Kodiak is a hammer-forged knife that is offered in a dizzying number of configurations, not even including custom engraving. The variant we’re concerned with here comes with elk antler as a grip material, and it sure does look great! Unlike many knife companies, Rapid River has a showroom you can visit in person.

MSRP: $175

Randall Knives 3-Piece Carving Set

Randall Knives needs no introduction here, however, we are pleased to take a look at a less-prominent product from their standard lineup—its 3-Piece Carving Set. The set comes with a 9-inch carbine knife, serving fork, and sharpening steel, all of which are finished with stag handles. The set includes a storage box and the company notes that you should not put them through the dishwasher. Randall Knives, of course, offers some very well-known classics in natural material handles, many of them available in their standard lineup. If you so desire, you can also take a look at having something custom-built, but you had best get your orders in now. The company website is currently taking orders for delivery in four years!

MSRP: $680

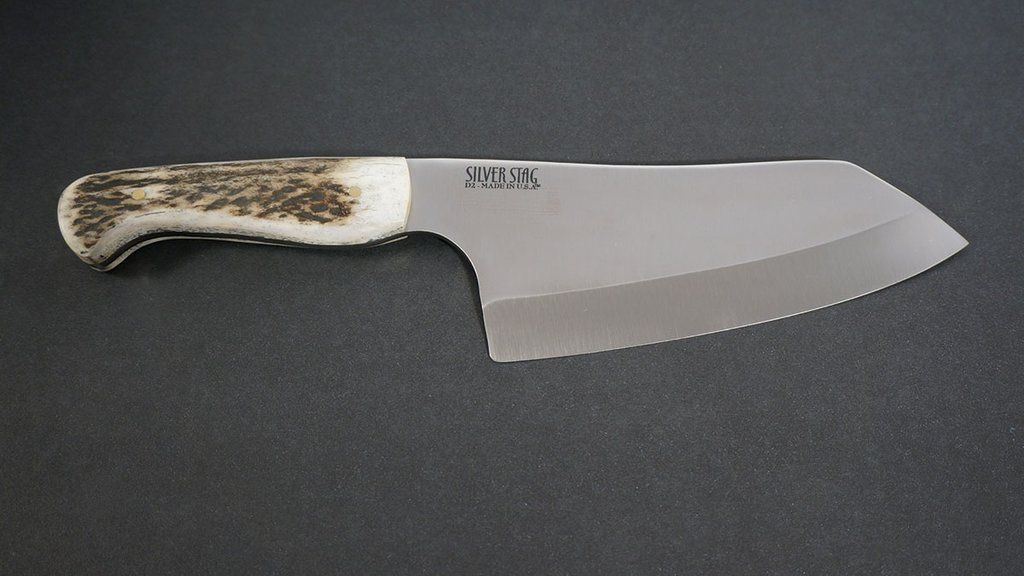

Silver Stag Universal Chef Pro

Silver Stag makes a great number of products that feature natural handle materials, but a standout example is the antler-handled Universal Chef Pro. This is an all-use kitchen knife that is at home in just about any setting—be it your home or base camp. The knife is ruggedly constructed and has a unique shape with a curved belly and sheep’s foot tip that allows it to be deftly handled for large tasks like carving down to fine dicing. Silver Stag offers a full line of antler-handled kitchen knives, as well as many other outdoor knives from filet knives to custom scrimshawed skinners.

MSRP: $218

More On Knife Handles:

- G10 Knife Handles: Are They The Best?

- Micarta: A Do-Everything Handle Material

- Feeling Good: 4 New Handle Materials

- Hall-Of-Frame Handles

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.