Sponsored Content

Raffir Offers Incredible Wood, Fossils & Composites

Raffir, a knifemaking supplier, offers products in three main categories: Raffir Wood, Raffir Fossils and Raffir Composites.

Raffir Wood is stabilized fine-grained wood. The stabilization process is a specially developed high-pressure resin treatment. After this process the material is stronger, more durable and obtains deeper grain patterns.

Our Raffir Fossils are real Ice Age mammoth fossils that are preserved with a similar process. These rare and special materials are made useful with the stabilization process.

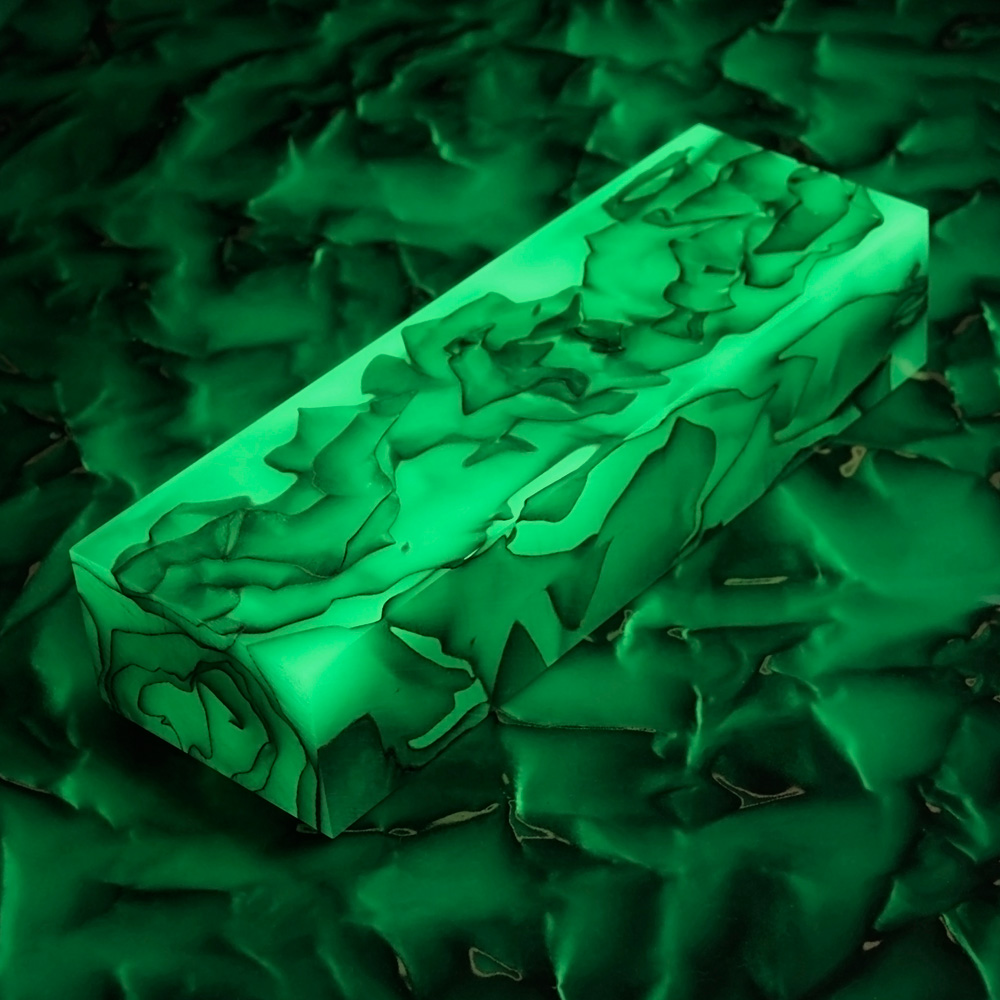

Finally, Raffir Composites are plant fibers or metals that are cast in a deep colored 3D resin matrix. The finished materials are hybrids with unique structures from the untreated material plus mechanical benefits from the durable resins.

Using Raffir Materials

Raffir materials are most often used for fine handles. However, this is far from the only application.

They are also used for accessories, jewelry, inlays, musical instruments, pool cues, fishing rods and more. Actually, they work well in most small- and medium-sized quality products. Use them where you want that extra edge to your products.

About Raffir

Raffir is taking a new approach to material design. Every day we strive to take something traditional and practical and turn it into an art form.

Usually, our costumers already make very appealing quality products, both as fine crafts and industrial high-end goods. So at first we have to ask ourselves: How can Raffir materials help our customers make even better products? Surely, they have to stand out from all the rest. They have to be more special, more beautiful, have a better story – simply be more appealing to the customers, all the while still meeting the requirements for strength, durability, machinability and safety.

This leads us to a whole variety of new materials. Every time we start a new project we want to create something original. To help us do that we even create entirely new manufacturing methods.

Careful selection is another way of insuring a high quality. Therefore, we use a lot of efforts on product development. Actually, for every product we put on the market there are about 10 more on our R&D shelves. And every time we launch a new product we set the bar a little bit higher. Thereby we ensure better and better products for our customers.

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.

When promoting a business like Raffir, it would be helpful to everyone you make interested, by placing an obvious link to their website/store. Though I note they do not even do that on their own youtube video. Of course, I can Google them but that is not the point.