Despite or perhaps because of its requirement for tight tolerances, the lockback has a substantial lineage.

According to Bill Claussen, co-author of Sheffield Exhibition Knives, the lockback has been around in various forms since 15th-century Spain. Other European cutlers—including the French, Italians and English—have produced lockback variants during the past 500 years or so.

The Buck 110: A Gamechanger

In the modern era, Claussen cites the Buck 110, which hit the market in 1964, as an industry icon.

“It changed the face of modern pocketknives,” he commented. “Although lockbacks had been introduced to the U.S. for more than 200 years, they were not made affordable and convenient in mass production until Al Buck introduced his knife. This knife was quickly adopted by sportsmen, tradesmen, truckers and other workmen as an ideal, all-around, heavy-duty work knife. Vintage 110s are hard to find today, and one in mint condition will cost a small fortune if you can find one.”

Production Challenges

Chairman of the board at Buck Knives, Cutlery Hall-Of-Famer Chuck Buck recognizes the pivotal role the 110 has played in modern lockback development, and acknowledges the challenges that surrounded the original premise of a practical production lockback.

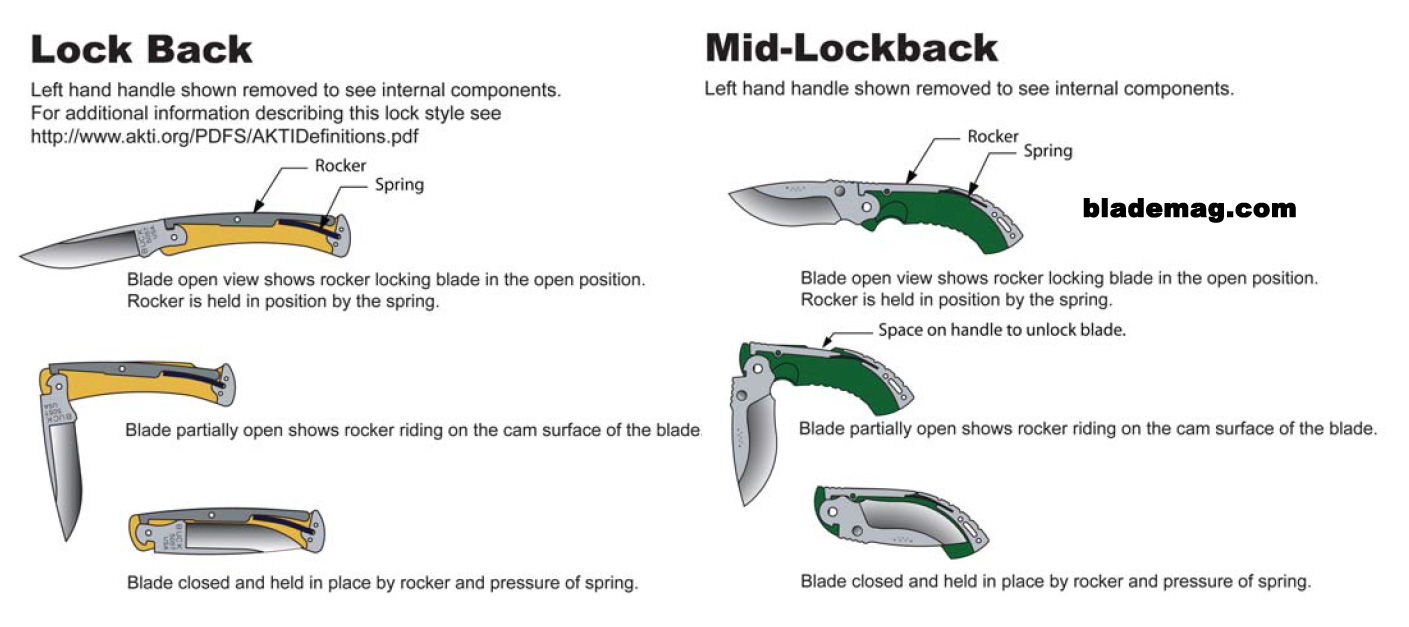

“The lockback actually is a bar that goes across the back of the blade with the spring under it, and when you push down on the bar it rocks on a stainless rivet,” he said. “So, that was always hard to get exact because you did not want it to be loose and it needed to fit perfectly.

“You need to do fine blanking of the blades to achieve that and for years components had been machined, but with fine blanking you can get that done. We worked with the design for quite a few months, and it was all new to us. That was in 1963. The first knives on the market totaled about 250 in 1964, and then in 1965 we ended up making about 10,000 of them. It just grew from there. The 110 continues to be one of our most popular knives, and we are producing them now at a rate of over 1,000 per day. We have a whole crew that just makes the 110 folding hunter. To Buck, it has been something that has sold every year, and it just keeps getting better.”

Over the years, there have been a few tweaks to the lockback design of the Buck 110. For example, during the 1970s it was discovered users were placing a great deal of pressure on the blade, and the brass rivet in the mechanism itself was shearing. The brass rivet was replaced with a stainless steel component, and the 110 continues to sell well around the world.

From large retailers to mom-and-pop hardware stores, from Main Street to Moscow, the Buck 110 is a knife user’s mainstay.

It’s Human Nature

Claussen asserts another aspect of the popularity of folding knives and of lockbacks in particular has to do with human nature.

“It’s their mystique,” he related. “People seem to have a fascination for complicated things, plain and simple. Th is is generally true in life and very specifically in the collecting field. Watches, clocks and other collectibles are favored because of their complication. The general rule, with all things being equal, is that the more complications, the more desirability, hence greater value. To have a locking feature with a knife definitely adds mystique, aura and increased value.”

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.