Premium Steels Require Premium Diamond-Coated Sharpeners

Many knife users/collectors opt for high-performance blade steels such as CPM S30V, CPM 154, 154CM, CPM S35VN, BG-42, CTS 204P, CTS XHP and others. These high grades of stainless offer maximum edge holding, though at a price—and that price comes due when you resharpen the blades. Since these steels excel at wear resistance and can hold an edge for a long time, it also makes them difficult to resharpen. It’s a tradeoff you must consider when buying knives with premium blade steels.

Ergo, especially if you’re going to sharpen the knives yourself, it’s imperative you buy a sharpener that can address such steels effectively. If you’re new to the super steels, not only is selection of the proper sharpener critical but the necessary investment of time is also required.

With the proper sharpener, that time can be kept to a minimum.

Enter Diamond-Coated Sharpeners

Historically, diamond-coated sharpeners are at the upper echelon for sharpening knives. They are the most durable and longest lasting. The tradeoff is price. They are generally more expensive but you must bear in mind that unlike other sharpeners that can break or eventually wear out, there is almost nothing to break or wear out with a diamond sharpener.

Once you buy it, if you can keep from losing it, it should last your lifetime.

AccuSharp Diamond Paddle Sharpener

AccuSharp’s Diamond Paddle Sharpener model 051C is a double-sided model featuring both coarse (320) and fine (600) grits. At a healthy .75 by 3.75 inches, it has a large diamond-coated sharpening surface.

The big surface enables the 051C to address all types of knives, from multi-blade slip joints to large fixed-blade hunters. It includes a sharpening groove for use with all kinds of hooks, darts and other pointed items. It features handles similar to a butterfly knife’s that fold up around the sharpening surface, protecting it from damage during transport or storage. The handles feature a secure gripping surface as well.

The 051C works very well. With a diamond sharpener, use light pressure and let the abrasives do the work.

The 051C works very well. With a diamond sharpener, use light pressure and let the abrasives do the work.

Too much pressure and you can dislodge the diamond particles, reducing the sharpener’s effectiveness. I like the sharpener’s two sides, which eliminate the need to carry a separate finer-grit sharpener to fine tune the edge. When done re-profiling the edge with the coarse side, just flip the 051C over and continue your work to refine the edge.

Another thing I like about the 051C is the rubber overmold gripping area. With or without gloves or wet hands, the sharpener is comfortable to hold. It never felt unsecure in my grip. Along with the rubber overmold, the thickness of the handles adds to comfort by filling my grip easier.

However, I can see where the girth can also be a downside, making the 051C difficult to stow in tight quarters like a zippered pouch or glove box.

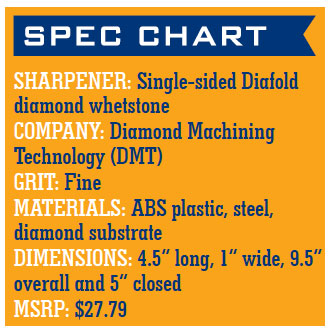

Diamond Machining Technology Diafold

In my opinion the most iconic product made by Diamond Machining Technology (DMT) is the single-sided Diafold diamond whetstone sharpener. DMT’s sharpeners are easily recognizable by their trademark round polka-dot sharpening surface. They offer near-perfect grit-size consistency across the sharpening surface.

The Diafold is a compact sharpener with a flat form factor, allowing it to be carried in a large pocket, toolbox, glovebox, tackle box or carry bag. The handles double as a carrying case, folding up to conceal the sharpening surface and protect it from damage during transport.

Each DMT sharpener is color-coded according to grit, so, once you learn the codes, it’s easy to identify each grit by its color. The clear handles make identification easy and are a nice touch, so there’s no mistake which grit you have.

Each DMT sharpener is color-coded according to grit, so, once you learn the codes, it’s easy to identify each grit by its color. The clear handles make identification easy and are a nice touch, so there’s no mistake which grit you have.

The Diafold works exceptionally well. It has been on the market many years and in my opinion is pretty much the gold standard when it comes to compact handheld sharpeners. It easily addresses all types of high performance stainless steels with ease. The fine grit carefully constructs the final edge keenly, and is for use only after re-profiling the edge employing a coarse-grit sharpener.

An improvement I recommend would be to make the sharpener a bit thicker to give the handles some width, which in turn would make it easier to hold—especially for an extended period of time sharpening several knives in one sitting.

Still, as is it functions well and, when the handles are folded, the thin profile makes it easy to pack.

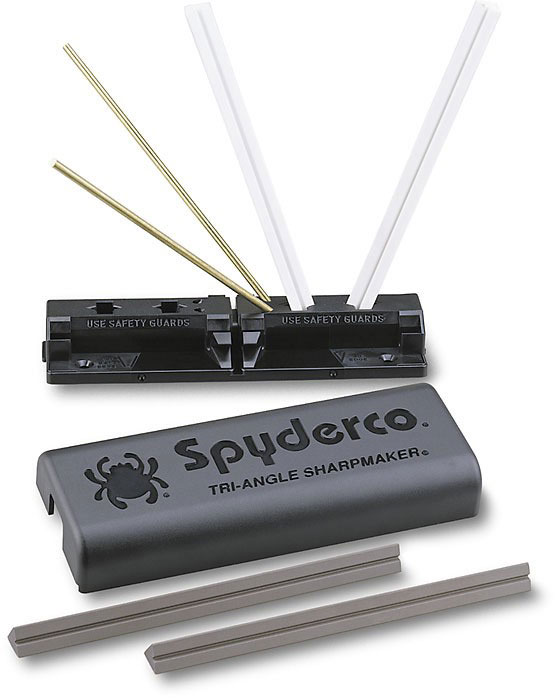

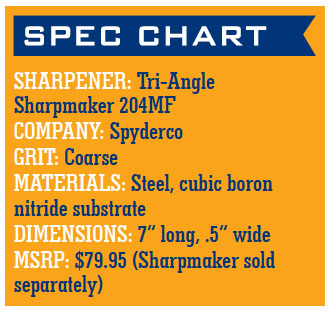

Spyderco Tri-Angle Sharpmaker 204MF

Spyderco’s Tri-Angle Sharpmaker 204MF has been an industry leader for many years.

“In the 1970s when [Mrs. Gail Glesser] and I started selling knife sharpeners at local fairs, we were buying and selling other people’s sharpeners,” begins BLADE Magazine Cutlery Hall-Of-Fame® member Sal Glesser, CEO and founder of Spyderco. One of the sharpeners the Glessers sold was a V-stick type that they liked, though they identified some of its shortcomings. “We invented the Tri-Angle Sharpmaker because, while similar to the [V-stick] sharpener, it solved many sharpening challenges/problems the [V-stick] couldn’t perform,” he says.

One of those problems is the V-stick model could not sharpen serrated blades. Enter the Sharpmaker’s triangular-shaped rods, which allow it to address both plain edges on the rods’ flats and serrations using the “points” of the triangle.

With the advent of higher-performance steels, the Sharpmaker’s ceramic rods were underpowered, so the company devised the 204CBN (Cubic Boron Nitride) Tri-Angle hones. The CBN hones work exceptionally well addressing dull or damaged blades. They can reprofile edges efficiently, handling not only the super stainless steels but all steel types. Like the ceramic Tri-Angle hones, the CBN easily addresses both plain and serrated edges.

As with the ceramic rods, a groove running the length of the CBN rod’s length allows for sharpening pointed objects and tools. The CBN material is what Spyderco calls a “super abrasive” second in hardness to diamond.

The CBN hones cost extra. The 204CBN complements the included medium- and fine-grit ceramic hones well. Once you re-establish the new cutting edge, switch to the medium and fine ceramic hones to further fine-tune it to razor sharpness. The CBN hones work on any blade length, fixed or folding.

The CBN hones cost extra. The 204CBN complements the included medium- and fine-grit ceramic hones well. Once you re-establish the new cutting edge, switch to the medium and fine ceramic hones to further fine-tune it to razor sharpness. The CBN hones work on any blade length, fixed or folding.

Once you set the sharpener up, start your blade from where the edge starts closest to the tang and run it down the hone, at the same time pulling the blade back toward you, ensuring the hone contacts the entire length of the cutting edge all the way to the tip. Hence, you’re doing two simultaneous motions—moving down the hone and pulling the blade back toward you. Do it all with light pressure.

An improvement I would recommend would be to include a set of CBN hones as standard with the Sharpmaker. The CBN hones speed up the process of edge recreation. Granted, the addition would increase the Sharpmaker’s cost but the increase would be justified.

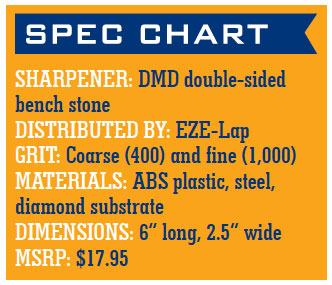

DMD Double-Sided Bench Stone

The DMD double-sided bench stone sports two different grits: a coarse 400 and fine 1,000. The base is molded ABS plastic and features wide, anti-skid rubber feet to keep the sharpener in place while working on a flat table, counter or bench. The sharpening surface sits in a cavity of the base. To change grits, flip the hone over and return it to the base.

A hex-like pattern on both sharpening surfaces removes the tiny metal particles so they won’t collect and clog the surfaces as you sharpen the blade.

A hex-like pattern on both sharpening surfaces removes the tiny metal particles so they won’t collect and clog the surfaces as you sharpen the blade.

Work with the DMD and discover the convenience of a double-sided diamond bench stone, a rarity among such stones. The coarse side easily and quickly re-establishes worn edges to sharp. After you establish the primary edge, flip the sharpening surface over to the fine side and fine-tune the blade.

The DMD did a great job on CPM S30V and CPM 154. Keep in mind that since this isn’t an angle guide-type sharpener where the angle is held consistent for you, extra care/consideration is required to get a nice edge.

Try using a permanent marker to color in the entire cutting edge on both sides of the blade. As you sharpen, note where the ink is removed and where it remains on the cutting edge. By doing so you can adjust your angle accordingly to capture the entire cutting edge and, therefore, keep the angle consistent for a sharp blade.

Keep Learning About Knife Maintenance

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.