Find out why the Spartan Blades Clandestina took home Blade Knife of the Year, thanks to its standout tactical design, top-tier materials, and unbeatable performance.

A deadly beauty, Spartan Blades’ Clandestina packages the best of both worlds. Yup, it’s a looker, but dang if it isn’t engineered to inflict damage.

The dueling personalities of the BLADE Knife of the Year aren’t surprising, given who cooked up this wicked fixed blade. Bill Harsey has built his reputation on designing robust outdoor and tactical knives.

A favorite of Army Special Forces and figures such as Col. Rex Applegate, Harsey work also has a certain lethal aesthetic to it as well. But even with operators enamored with his work, Harsey’s Spartan project has an appeal beyond serving in foreign conflicts.

Spartan Clandestina Specs

Knife Type: Fixed

Blade Type: Spear Point

Blade length: 5.5

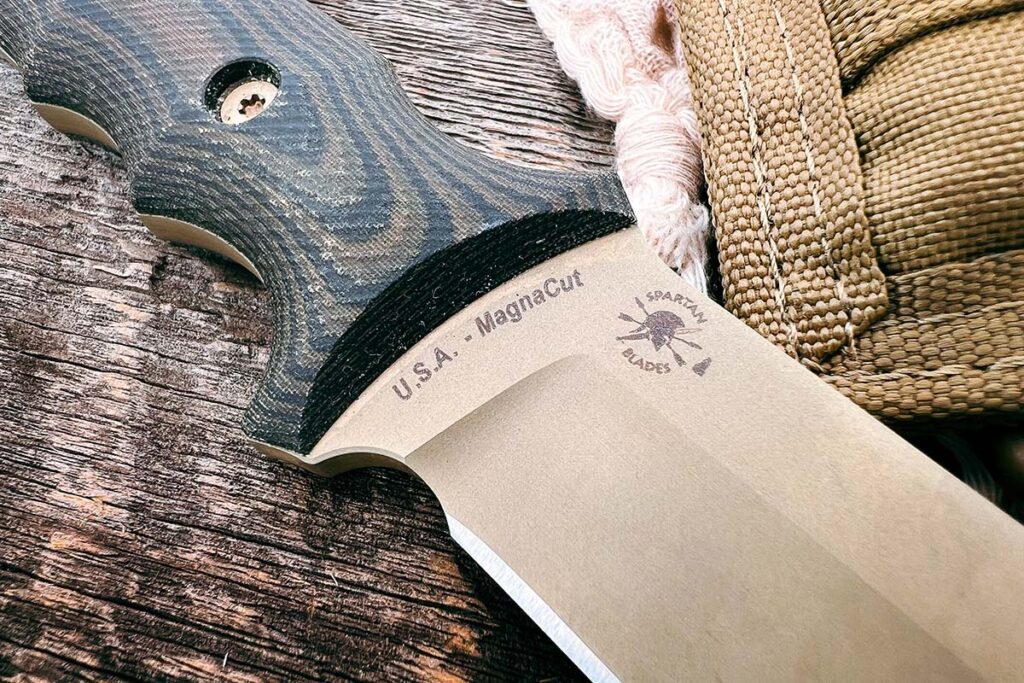

Blade steel: CPM MagnaCut

Blade grind: Flat ground

Handle material: Canvas Micarta Black and Camo

Blade Hardness: 61-63 HRC

Overall length: 10 3/16”

Sheath type and material: MOLLE and Kydex options

Special features: Available in Black and FDE PVD Coating, Double Deep Cryogenic Treatment

MSRP:

Pros

- Superior Ergonomics

- Premium Blade Material

- Sheath Options

Cons

- Large For Everyday Carry

- High Price Point

- Niche Design

Spartan Clandestina Handle

Oddly enough for a knife review, I’m going to start at the handle. There’s a method in this madness, given this feature is what gives the Clandestina its edge.

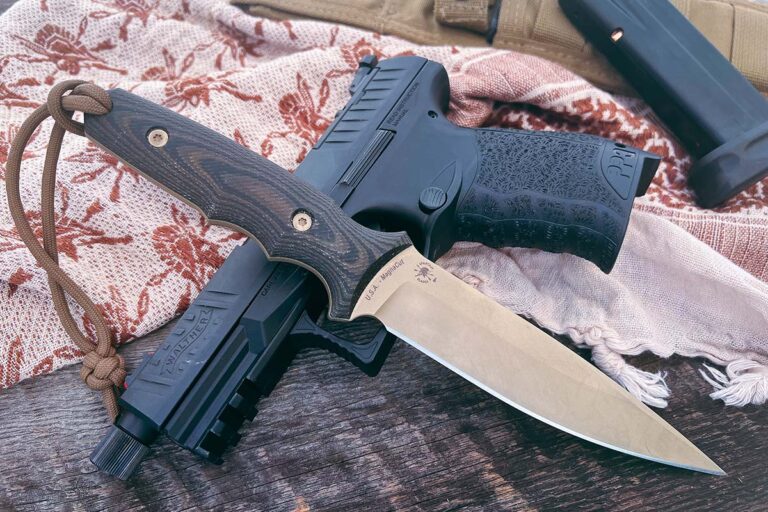

The canvas Micarta handle is slim in profile, even understated, yet sports big-league features.

Boasting two-finger grooves leverage the use of the middle finger to help stabilize the knife in the user’s grip and help lock it in for security. The double guard is somewhat subtle but does its job very well.

The entire handle is rounded and therefore, extremely comfortable to hold. No hot spots or harsh angles to get in the way. Overall outstanding ergonomics make the knife one with the hand. In brief, it’s pure Harsey all the way.

Micarta itself was an excellent choice for the tactical fixed blade—it’s lightweight yet strong. Comprised of fabric saturated in phenolic resin, it is also impact-resistant and fluid-resistant.

These attributes were engineered in the Clandestina with combat in adverse conditions in mind. Yet, the everyday user benefits, given it’s a robust system that should last a lifetime. Not to mention, the Micarta is available in a multitude of colors, besides my black and camo.

Spartan Clandestina Blade

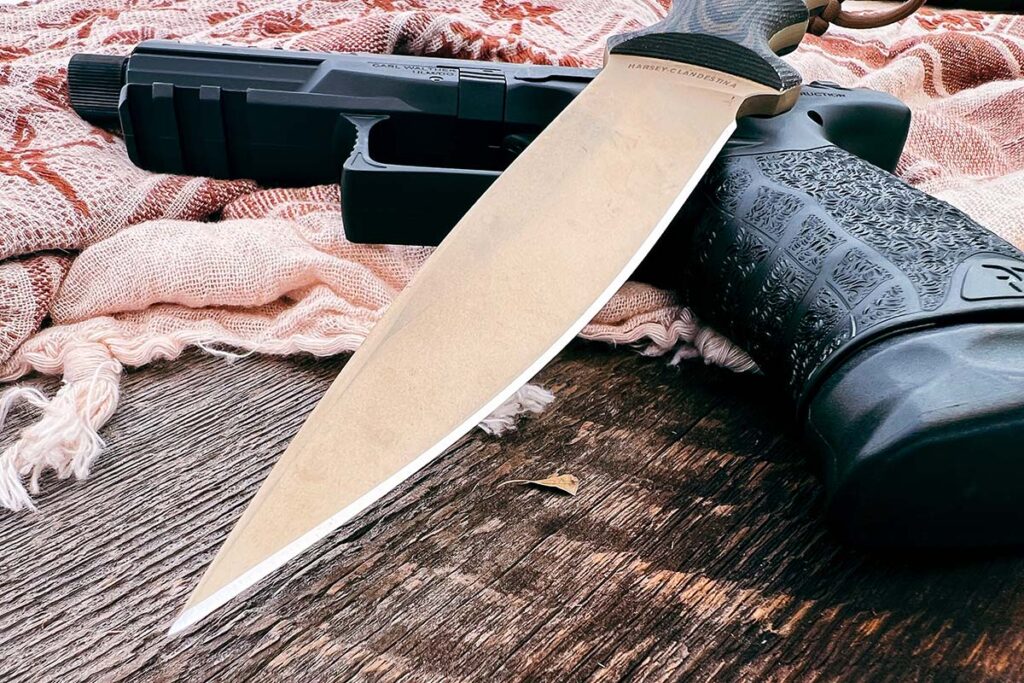

From the understated to the obvious—the knife’s nefarious.

At 5.5 inches long and sporting a spear-point profile, the Clandestina was designed for more than opening boxes. A testament to this was Spartan opting for premium CPM Magnacut stainless steel.

Know for its capability of long-term edge retention, the metal makes the ready to slash or perforate with ease. Again, this material also has superior corrosion resistance, adding to the overall hardiness of the knife.

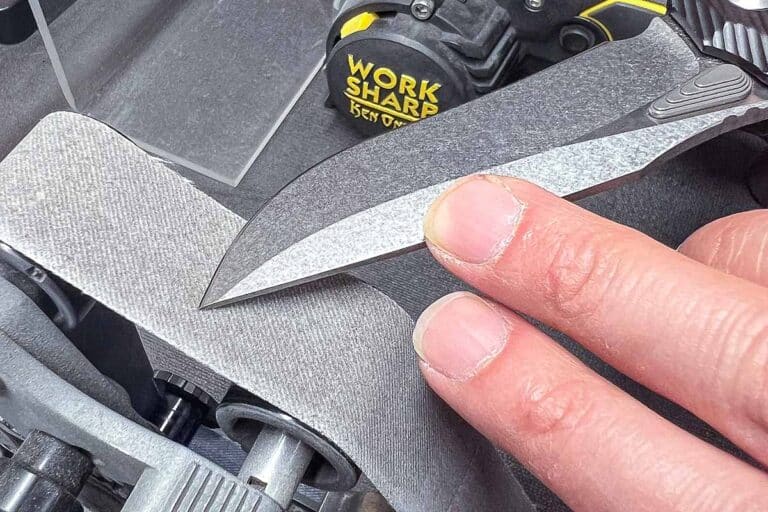

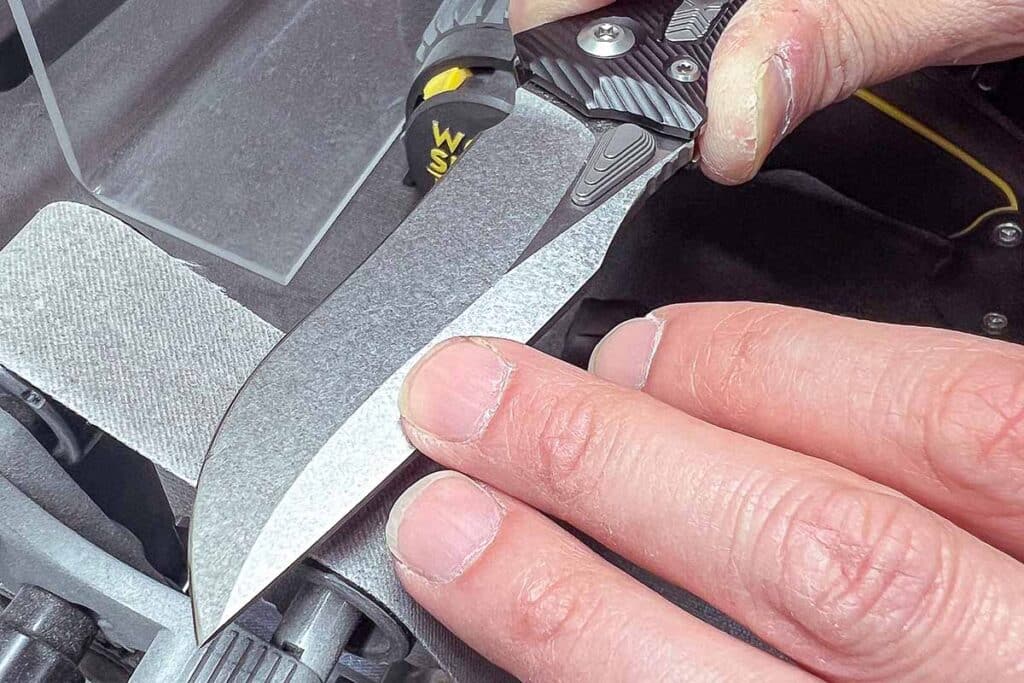

The blade is flat ground and the factory edge right out of the box is outstanding. I found nothing needed to be done to improve the edge, I just took it out of the box and put it right to work!

While larger than most folks’ carry option, the blade length isn’t over the top. I found it nearly perfect for belt carry, hitting an elusive sweet spot many fixed-blades miss.

Spartan Clandestina Sheath

Sheath-wise, there are two options – form-fitting Kydex or a tried and true ballistic nylon. The sample knife shipped to me with the latter.

I found the sheath is very well made, with double sewn edges and a button snap retention strap to hold the e knife in. A large belt loop allows the use of various widths of belts to be used.

Should you opt for Kydex, the sheath is of a riveted construction with a belt loop attachment. The form-fitting sheath locks up around the integral guard of the handle. There are two MOLLE straps that also double as belt loops.

Testing The Spartan Clandestina

Putting the Clandestina to work is nothing short of an excellent experience.

All of Harsey’s tactical fixed blade design expertise comes into play here, and you quickly realize you have a piece of serious bladeware in your possession. It makes slicing cuts with brash confidence thanks to the excellent factory edge coupled with the flat grind.

The blade thickness tapers down progressively to the tip, allowing it to have the ability to do some serious piercing without being too thin where accidental breakage can occur. The overall blade profile is somewhat dagger-like, as you will notice.

The handle is downright comfortable. It allows the user to obtain a secure grip at all times, instilling and promoting user confidence. Thanks to the dual finger grooves, these allow the slender handle to have such a great grip quality. Locking your grip on the handle, it feels very stable and unlikely to rotate.

Furthermore, when you grip the handle and allow your thumb to rest on the blade spine, you can feel how secure this choke grip is and the knife is very controllable in this grip. Whittling and wire stripping are two such tasks that this grip facilitates. Simply put, the Spartan HARSEY Clandestina is built for use.

Short Cut

It’s definitely not a toy! Use it with confidence and use it hard. Spartan Blades’ craftsmanship skills are highly rated consistently, with each knife they turn out. You cannot go wrong with choosing the Clandestine.

More On Tactical Knives:

- Tactical Knives That Pass The Test

- Spartan Blades Poros Review

- Tactical Fixed Blade Knife Buyer’s Guide

- 5 Best Tactical Pocketknives: Perfect EDC Options

![Work Sharp Ken Onion Elite Mk2 Review [Hands On] Work Sharp Ken Onion Elite Mk2 Review [Hands On]](https://blademag.com/wp-content/uploads/Ken-Onion-WorkSharp-MK.2-15-768x512.jpg)