Knowing How To Use A Whetstone, Or Sharpening Stone, Can Restore A Dull Blade And Should Be Part Of Regular Upkeep For Your Knives.

There are many inexpensive ways to sharpen your knives at home, but nothing feels the same as sharpening your knives on a whetstone. Used for centuries around the world to keep an edge on everything from swords to kitchen knives, the whetstone is an intimate, precise way to maintain your knife’s edge and bring it back to life.

The “whet” in whetstone has nothing to do with being wet or any type of moisture. It comes from the Old English term “hwettan” which means “to whet or sharpen.” Coincidentally, most whetstones do need some type of moisture for top performance. In all cases, this means water or oil. However, a majority of stones you’ll find in stores or online–particularly for kitchen use–will be waterstones.

Oil Stone Vs Waterstone

Honestly, in some cases, there is no difference.

The preference of lubrication–water or oil–is left up to the user. Both will do the same job, swarfing the surface of the stone so it does a better job sharpening.

However, there are other cases where one or the other must be used with a particular stone. Natural sharpening stones, for instance, mostly use water. Rub them down with oil and you’ll render them useless.

Manufacturers will spell out whether your particular whetstone is water, oil or both.

The main difference between whetstones that use oil and whetstones that use water is that waterstones are softer so the old abrasive material breaks off faster than an oil stone. This means you’re sharpening on fresh stone material more consistently.

Waterstones are also less messy and easier to clean vs oil stones, which adds another point in the bucket for waterstones. Waterstones also come in more grit varieties than oil stones.

Oil stones, especially those made of novaculite, are a traditional sharpening stone, and many are quarried in America, specifically in Arkansas.

Differences In Grits

You’ll see stones of all types come in a variety of grits. The lower the number, the more coarse the grit. The more coarse the grit, the more material gets removed with each pass of the knife.

For at-home sharpening, grits in the range of 1,000-8,000 should be more than enough. However there are stones that come as coarse as 120 and as fine as 30,000. Consider these specialists and stick to the common grits for most jobs.

Whetstone Accessories

While there are many gizmos and accessories out there to help with your whetstone sharpening, there are two that stand above the rest. You can see them in the photo at the top of this article.

The first is the stand for your whetstone. This should come with the stone when you purchase it. You do not want to lay your stone directly onto your table or countertop. It can slide, and mixing sliding things with sharp knives is a recipe for losing a finger.

The second is that little thing to the right of the stone. It looks like a chip clip, but it’s actually an angle guide. Some will clip onto the top edge of your knife while others might need to be strapped to the stone itself. Either way, the angle guide will help set your sharpening angle and allow you to maximize each pass of the blade across the stone.

I’ve used a 1000/6000 waterstone for years to keep my kitchen knives sharp. You can find plenty of quality 1000/6000 whetstones online for under $40. But having the stone doesn’t account for much if you don’t know how to use it. I pulled out my sharpening set up to help give you a step-by-step breakdown of how to sharpen your knives with a whetstone.

Step 1: Get Your Equipment

Ready to start sharpening? Hold up a minute. You’ll need more than a whetstone and your knife.

In addition to the obvious tools for the task, I start with a whetstone stand, a container of water and a spoon (you heard right).

There are special notes on a couple of these items.

The water container is to prep the whetstone and should have some specific attributes. I want a deep container so the stone can sit in it and fully soak. These babies are thirsty, so you can’t just dab water on one and expect it to work.

Here I’m using a baking dish, but a plastic tub or kitchen sink work equally as well.

The spoon … no, you’re not taste testing your knife’s edge. It’s there to literally spoonfeed the stone more water during sharpening to clear off the shavings.

Step 2: Soak The Whetstone

Here’s the speedbump of the process.

As mentioned, whetstones require a good soaking before use. This isn’t a splash-and-go process.

Plan to let your stone sit fully submerged for a good 10 to 20 minutes before it’s primed for use. There’s a simple way to tell it’s good to go.

Plunge that baby into water and you’ll see it bubble like an aquarium aerator. Quite literally, this is the stone drinking up water in its microscopic pores and displacing air in the process.

As time goes on, fewer and fewer bubbles pop out of the whetstone (see the above picture). When it’s none or next to none, you’re good to go.

Step 3: Secure The Stone

OK, this sounds obvious. But it must be said–you must secure your wetstone before sharpening.

Not only does this stave off a tongue lashing from your significant other, ensuring you don’t scratch up the counter or dinner table. It also keeps your digits from getting cut up.

In most cases, you’ll have a holder that, well.. holds the stone. If you don’t, never fear, a towel or rag makes a dandy impromptu stone holder.

Whatever the case may be, make certain your stone isn’t going anywhere before you actually begin sharpening.

Step 4: Determining The Sharpening Angle

Rubber, you’re almost ready to meet the road!

Before you actually start scraping away precious material to create a fresh sharp edge, you need to determine exactly what angle to sharpen at.

Some knives require a somewhat uncommon angle to sharpen. This is spelled out in the owner’s instructions if this is the case. Lose those, check the company’s website, these vital specs are usually there.

However, in most cases–a vast majority–20 to 25 degrees is the best angle to achieve a good cutting edge. And you don’t even need a protractor to determine this pitch.

Think of it this way, the edge pointing straight down at the stone is at 90 degrees. Tilt the blade halfway down, now the blade is at roughly 45 degrees. Tilt the knife halfway again and, there you are about 22.5 degrees–a sweet spot for a good edge.

Or you can go the easy route and use an angle guide, mentioned earlier in the article.

Step 5: Course Sharpening

Start with the lower grit, which in this case is 1,000. It takes off more material and gets the edge almost all of the way back to razor sharpness.

Usually, I do 10 passes on each side of the blade, but I fully sharpened my knives a few weeks ago and just did two here as a demonstration.

Keep the blade angled between 20-25 degrees to get the best possible results.

Step 4: Turn The Stone Over & Sharpen With The Finer Grit

I finish with the fine grit, 6,000 on my whetstone.

You’ll notice each time I pass there’s some new metal shavings on the stone. That’s the swarf. It’s fine for your knives if you leave the swarf on the stone as you sharpen, but you can also wash it away with some extra water.

Again, like the coarse grit, I usually do 10 passes on each side of the knife.

Step 5: Wash Off Your Knives & Clean Up

Once you’re done sharpening you should rinse your blades and wipe them dry with a towel. Once your knives are accounted for, give your water container a thorough cleaning. I used a baking dish, and it’s important to fully clean it so you aren’t ingesting microscopic metal shavings.

For the stone itself, I double check that it’s secure in its holder and leave it out overnight to let the water evaporate out of it. Once it’s completely dry I put it back in its spot in the drawer.

And there you have it, a simple, straightforward guide showing you how to sharpen your knives using a whetstone.

Editor’s Note: This article was written by Mike Ableson.

Read More

- Best Honing Rods: A Complete Buyer’s Guide

- How To Use A Knife Sharpener

- 5 Best Electric Knife Sharpeners

- 5 Best Pocket Knife Sharpener Options

- 3 Best Sharpening Stones

- 5 Best Knife Sharpeners

Best Miniature went to Grace Horne for these full-functioning scissors. They were handmade by her with watchmaker tools underneath a microscope.

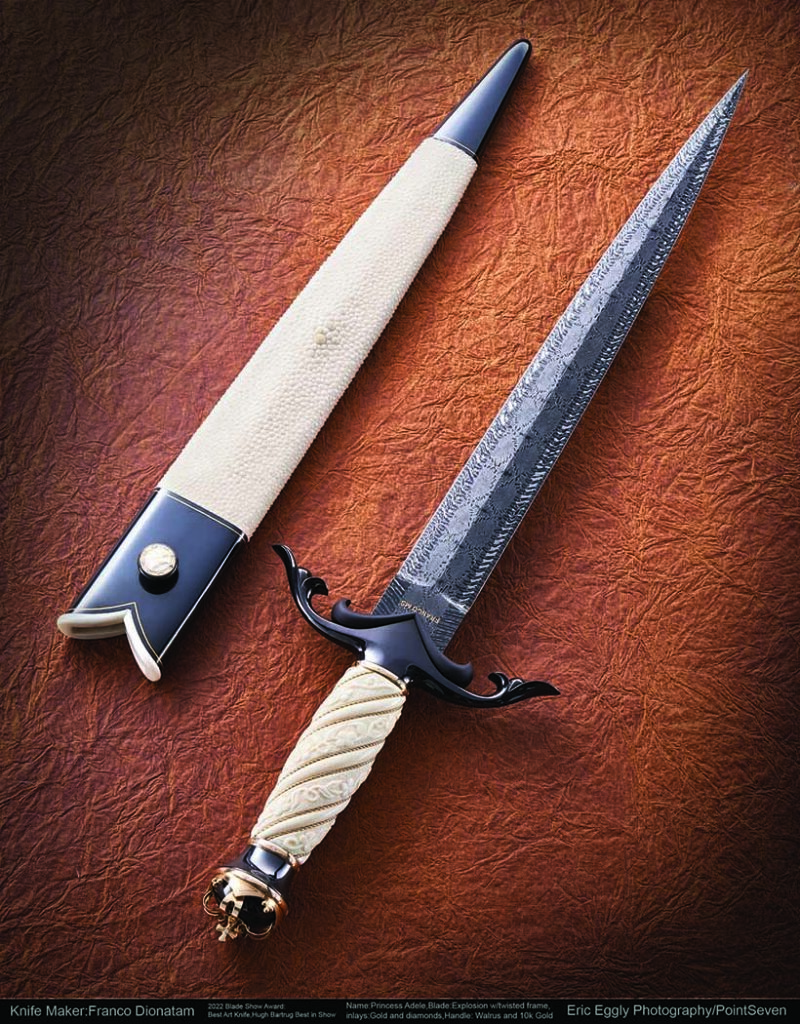

Best Miniature went to Grace Horne for these full-functioning scissors. They were handmade by her with watchmaker tools underneath a microscope. Best Tactical Folder: Dmitry Sinkevich

Best Tactical Folder: Dmitry Sinkevich

Best Slip Joint: Luke Swenson

Best Slip Joint: Luke Swenson Best Handle Design & Best New Maker: Fabio Barros

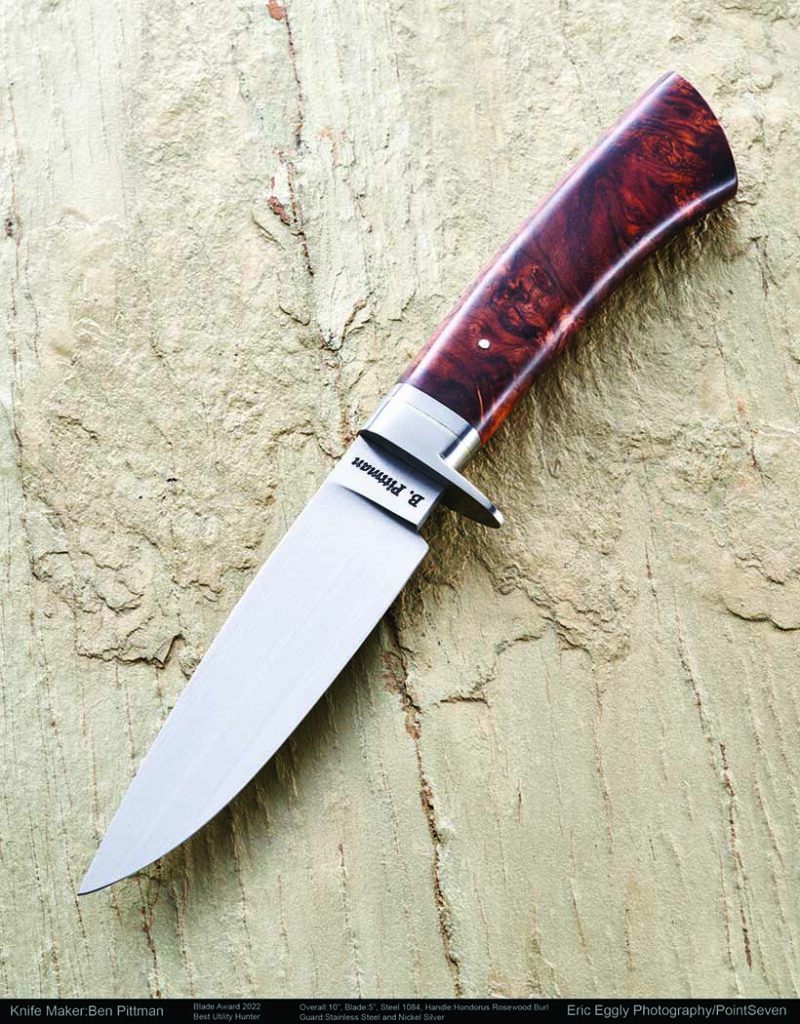

Best Handle Design & Best New Maker: Fabio Barros Best Utility Hunter: Ben Pittman

Best Utility Hunter: Ben Pittman Best Fighter: Henning Wilkinson

Best Fighter: Henning Wilkinson Best Sword: Vince Evans

Best Sword: Vince Evans

Best Collaboration: Seth Lopez & Leah Aripotch. Lopez forged the knife while Aripotch created the stand.

Best Collaboration: Seth Lopez & Leah Aripotch. Lopez forged the knife while Aripotch created the stand.

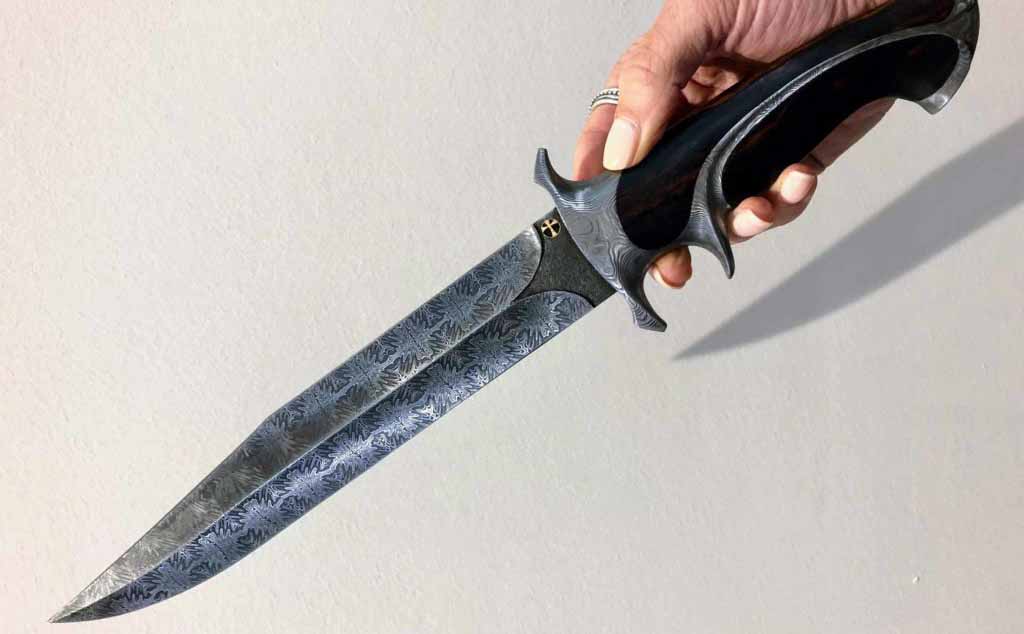

Best Damascus: Mike Quesenberry

Best Damascus: Mike Quesenberry Best New Maker: Fabio Barros

Best New Maker: Fabio Barros Best Kitchen Knife: Will Stelter

Best Kitchen Knife: Will Stelter Best Of The Rest: Dmitry Sinkevich. Sinkevich said that the design was inspired by a combination of the ulu knife and watch rotor.

Best Of The Rest: Dmitry Sinkevich. Sinkevich said that the design was inspired by a combination of the ulu knife and watch rotor.

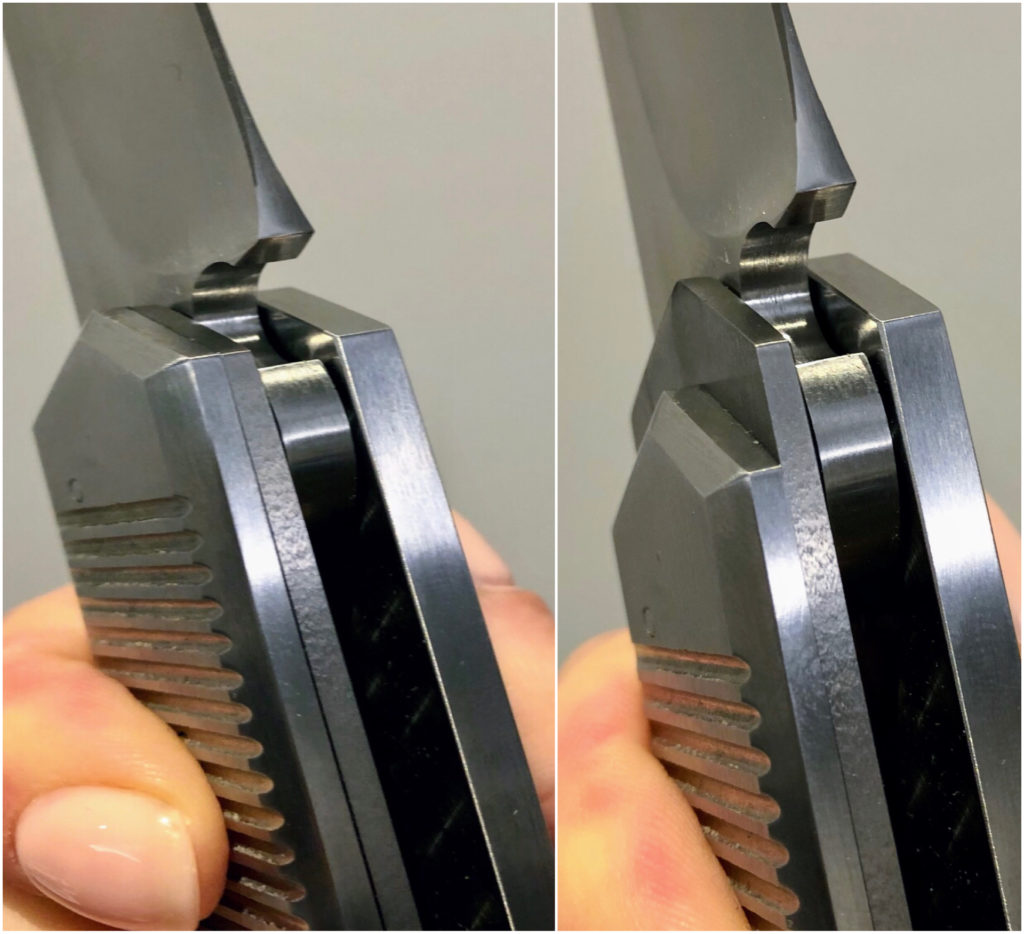

Spyderco Military 2

Spyderco Military 2 Asheville Steel Warlock

Asheville Steel Warlock MKM – Maniago Knife Makers Miura

MKM – Maniago Knife Makers Miura Civivi Orthrus

Civivi Orthrus Lionsteel Eggie

Lionsteel Eggie Sencut Sachse

Sencut Sachse Pro-Tech Ultimate Collection Terzuole ATCF Auto

Pro-Tech Ultimate Collection Terzuole ATCF Auto Pro-Tech Terzuole ATCF Auto

Pro-Tech Terzuole ATCF Auto Heretic Wraith Auto

Heretic Wraith Auto Bradford Paring Knife

Bradford Paring Knife