It Never Disappeared, But The Tactical Fixed Blade Has Long Been Overshadowed By Other Knives. Now It’s Back In A Big Way.

When developing a new product or their version to enter an established market, most industry professionals rely on product lifecycle management. The basic version has four steps—development and introduction, growth, maturity/stability, and decline—and applies to most all products that are sold, including custom knives.

However, trends must be accounted for in the cycle with the added step of saturation, a step that is particularly applicable to custom knives. As a result, the lifecycle for custom knives has five steps: development and introduction, growth, maturity/stability, saturation, and decline.

The most recent example of saturation in the tactical folder was seen over the past 10 years, even though the knife began to take off in the early 1990s. Tactical folders featuring new openers, stabilizers, bolsters, and handle materials were all the rage. The growth was spurred when both makers and collectors who had been respectively making and collecting other types of folders came into the market.

Prices spiraled upward and it seemed the good times would never end. In the case of tactical folders, market maturity and saturation occurred almost simultaneously. The decline began when those who overpaid for a tactical folder hoped there would be the next collector to sell or “flip” the knife to. They found out that the next collector wasn’t there and they were now the owner of a knife on which they would never recoup their investment.

Custom Knife Copies

When a collectible or a market gets hot within custom knives, makers want to join that market sector, as the path has already been made. I have always been struck by the dichotomy of many of the custom knifemakers I have dealt with over the past 30 years. Many perceive themselves as artists, yet are quick to embrace a trend or flat-out copy other makers’ work.

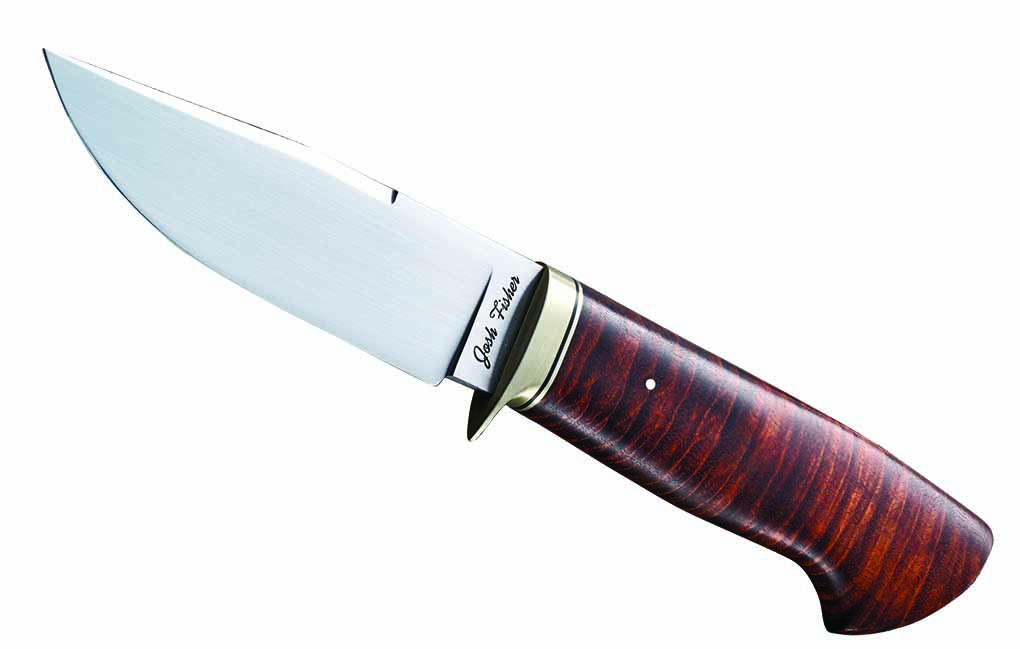

A case in point: those who make their versions of knives created by BLADE Magazine Cutlery Hall-Of-Fame® member Bob Loveless. Without a doubt, his custom knife designs are the most copied in the world. Why don’t those who reproduce Loveless designs build their own designs instead? The answer is simple: the path has already been made.

It is much easier to copy someone else’s work and then compete in that very saturated market. With few exceptions, most such makers get lost in that market as more and more enter it every year.

The idea of a custom knife is that it is made by a craftsman who can incorporate your ideas into a piece that will meet your needs, and not just create a copy of a knife others made famous.

Rising Tides

The aphorism “a rising tide lifts all boats” is associated with the idea that an improved economy will benefit all participants. This is exactly what has happened to the custom knife market over the past decade. In other words, the high prices many tactical folders received over the past 10 years made other market sectors seem like a bargain. Meanwhile, the prices realized for every other sector of the custom knife market also rose.

Currently, this is obvious in three sectors: slip joint/multi-blade folders, chef’s knives, and forged blades. As the realized prices for these knives continue to increase, the market is becoming saturated.

The commonality with the three markets is that all are seeing booms in numbers of makers. Conversely, they are not bringing enough additional collectors to support the makers in the increasingly saturated markets. Makers are quicker to pivot to new markets than collectors, primarily due to the makers’ ability to potentially increase their sales.

Cyclical Nature Of Knife Trends

The custom knife market is a circle. The top half is folders and the bottom half is fixed blades. We knife enthusiasts have all witnessed the circle moving from folders to fixed blades. Almost without exception the reason it moves is because of pricing. Most custom makers do not know their position in the market. Subsequently, they do not price their knives commensurate with the market. The custom knife buyers will sort that out.

Demand and value for the money will separate those makers who continue down the market sector path and those who do not.

One of the trends I noticed at BLADE Show 2021 was the reemergence of tactical fixed blades. Like most custom categories, tactical fixed blades never went away completely. Instead, they were just overshadowed by the more popular market sectors.

The Meaning Of Tactical

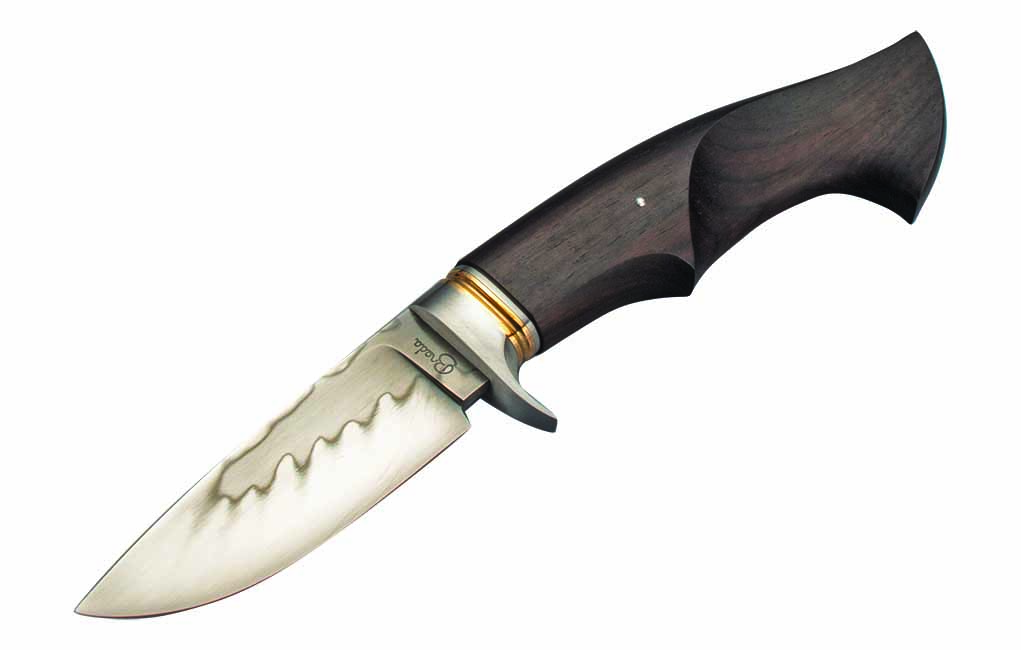

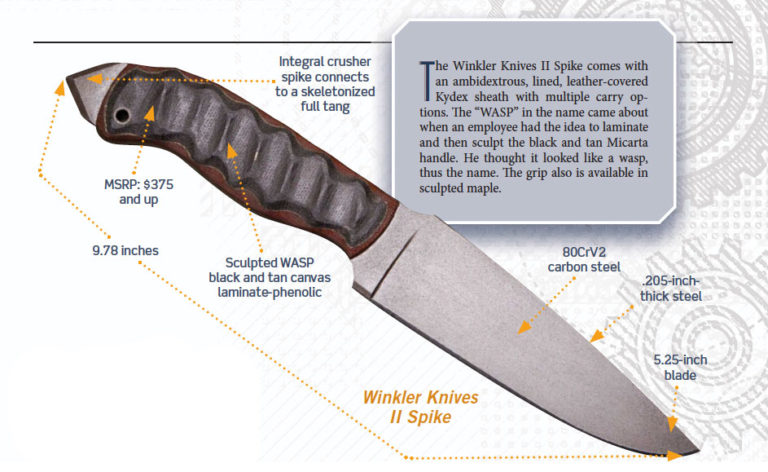

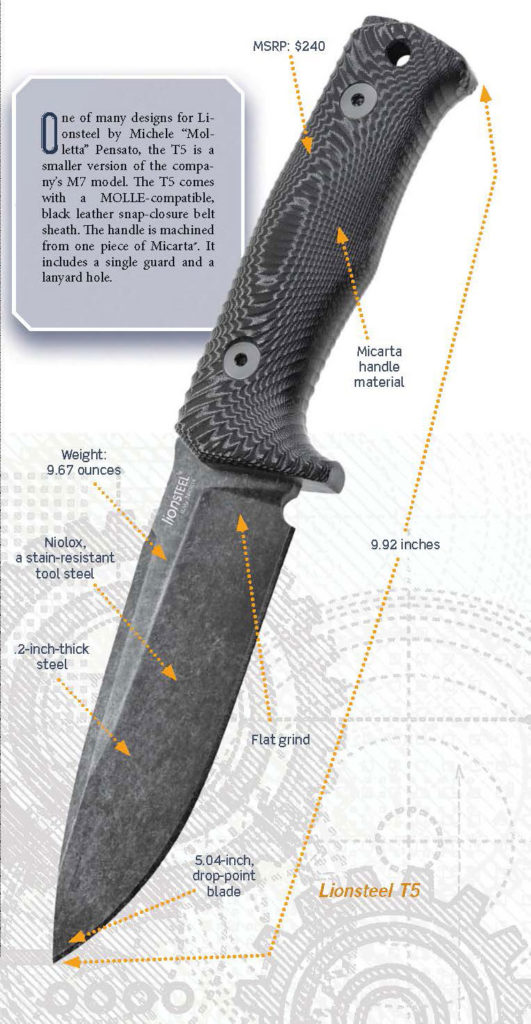

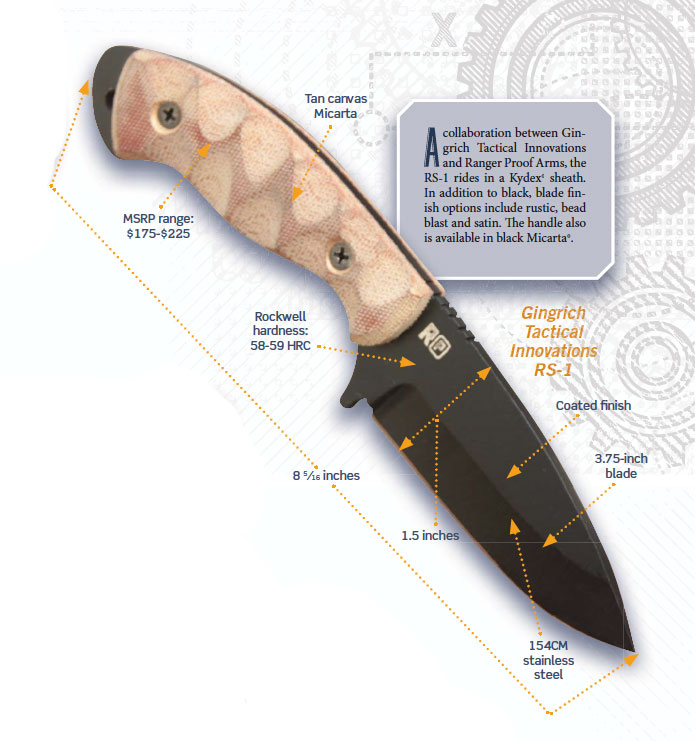

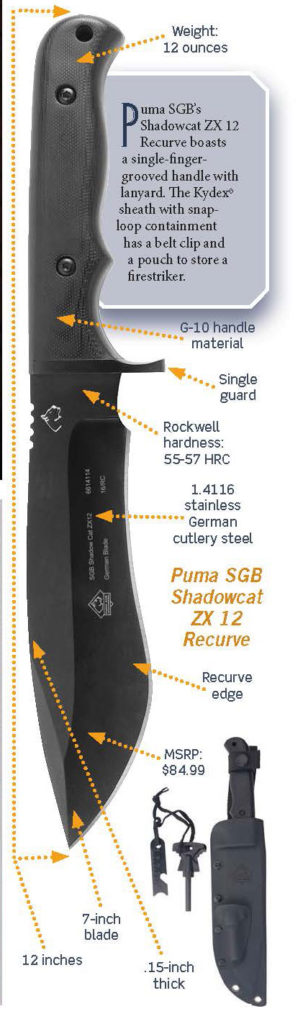

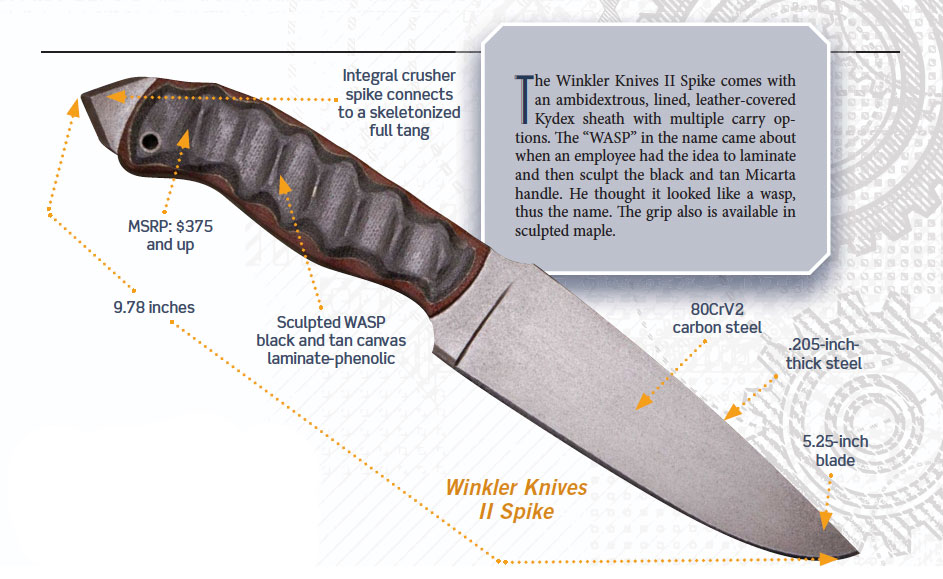

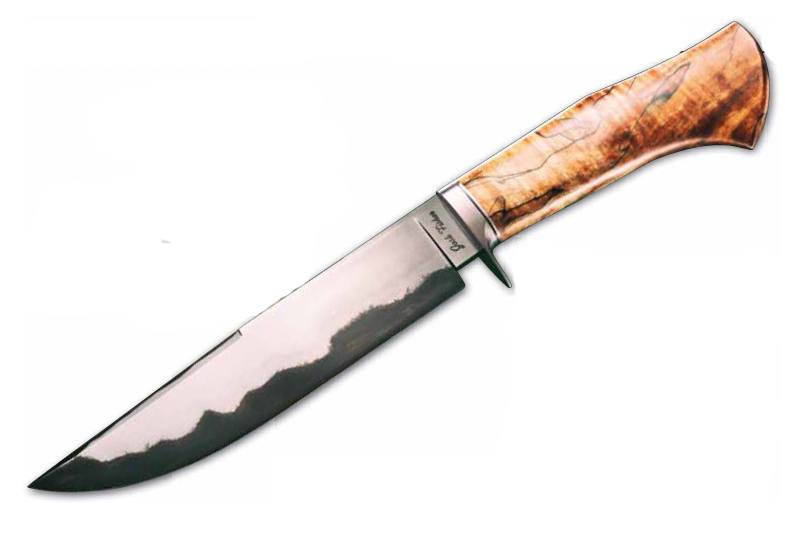

Sometime around 1995, the marketing term tactical was created to identify the look of a particular knife market sector. The concept was a simple one: it was primarily the look of the knife. The blade had a non-reflective finish that could be bead blasted, tumbled, coated, etc.

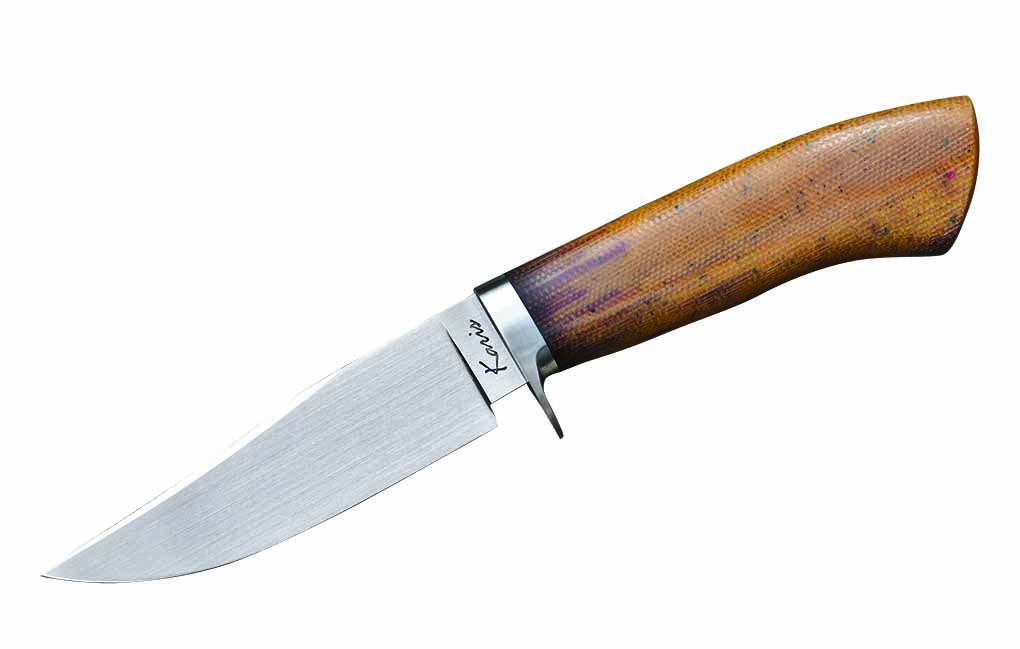

Unlike the latest iteration of tactical folders, if a tactical fixed blade had a damascus blade, it was a damascus bowie, fighter, hunter, etc. If the blade had a mirror finish, it was a presentation or art knife. The tactical definition indicated that if the knife had a guard, it also should feature a non-reflective finish. The handle material would be synthetic, that is, Micarta®, G-10, carbon fiber, etc. A natural handle material on a tactical knife would move the knife into another category.

Tactical fixed blades can range from practical to fantasy, neck knives to huge choppers. I bought my first custom tactical fixed blade in 1984, so I’m a fan! I am also a user and collector of knives from this market sector.

Today the advantage of the tactical fixed blade market sector is it offers knives for all budgets. The knives also offer the biggest steel selection of any market sector. Stainless, powdered, and carbon steels are all on the menu.

It will be on you to do your homework about what different steels will and won’t do for your tactical fixed blade. Rockwell hardness and heat treating will also come into play, as these knives are designed and built to be used. Hype is very pervasive in this market sector. This is why homework is necessary for the user/collector. Do not rely on the thousands of internet commandos and “experts” for your information.

Experienced and entry-level makers alike in the market build tactical fixed blades that feature a blade and two pieces of handle material combined in a utilitarian design featuring a cool look that catches the buyer’s eye. With such knives be sure to check for unwanted sharp edges usually found in squared-off integral guards, etc., and also price. These knives should generally sell for $500 or less.

Options For Collectors

For custom collectors, numerous options are available dating back to the 1930s. To not step on anyone’s toes, I will say these are the tactical fixed blade makers I have or have had in my collection: RJ Martin, Rod Chappel, Bill Luckett, Bob Terzuola, GW Stone and Ralph Bone, and Cutlery Hall-Of-Famers Jimmy Lile, Dan Dennehy and Gil Hibben. There are plenty to choose from.

Before you start writing to the editor complaining about my glaring omission, I intentionally left Walter Brend off the list above. While I do have Walter’s work in my collection, it is not a collectible per se. The knife is in far from mint condition. It is the knife I have had with me since 1986.

For high-end users, I can assure you it is the finest tactical fixed blade in the world. I do not make this statement lightly. Having handled more than my fair share of custom knives, I feel very confident in my statement. While I understand that most who buy Walter’s work put the knife in a collection, for those of you who own one of his knives and have never used it, more the pity.

Buy The Knife For You

Whether you are looking for a good, solid budget-conscious user, a collectible, or the best the category has to offer, I recommend you check the emerging knives in the tactical fixed blade market. Do your homework to help with hype and enjoy using your knives. After all, that’s what they’re meant for!

Read More