Understand how and why custom hunting knives cost what they do.

When I attend shows, one of my main goals is to talk with knifemakers and check the prices of various custom knives. One of the best shows to do that is the BLADE Show. This past June my goal in the Cobb Galleria Centre in Atlanta was to talk with 50 custom makers to get their takes on trends, material prices, overall demand, etc., regarding the knives they make and sell.

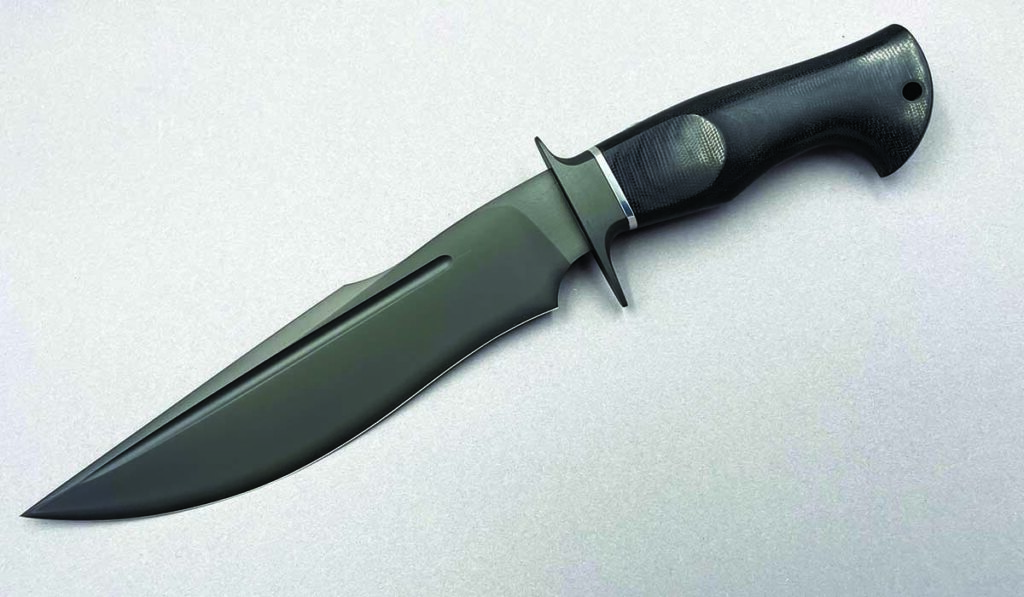

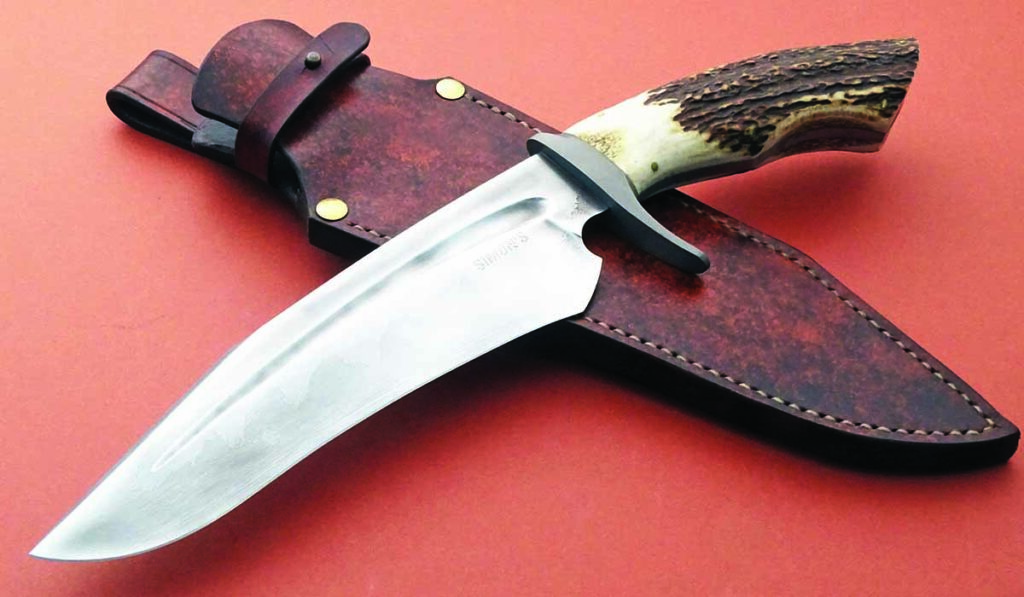

The custom knife that dominates the fixed-blade market is the hunter. This is due primarily to the fact that there seems to be an endless variety of hunting knives that can be made, and they usually have a lower price point than many other custom knives. Unlike other customs, hunting knives are often bought for use. Consequently, they are frequently tested by many users, from the casual outdoorsman to the professional hunting guide. The firearm may dispatch the game, but the knife provides the meat and potentially the trophy the taxidermist creates.

Over the years, thousands of articles have been written on and about hunting knives, including a few by this writer. In this article, I want to discuss not types or designs but pricing on knives in the hunter category.

Custom Hunting Knives Cost

Several factors go into the cost of building or making anything. Most makers need a place to make the knives, usually a garage or a shop. Next comes the equipment, which varies from maker to maker. Belts for grinding, polishing and putting an edge on the blade can be one of the more costly items a maker utilizes. Electricity, propane or wood provide the energy to work the materials that become the knife. No matter how the knife is built, these are typical costs shared by most makers. The costs vary depending on the prices of the materials to make the knife. Steel, guard/bolster material, handle material and leather if a sheath is required all impact the finished knife’s price, as will the maker’s skill at using these materials.

Custom Hunting Knives Blade Steel

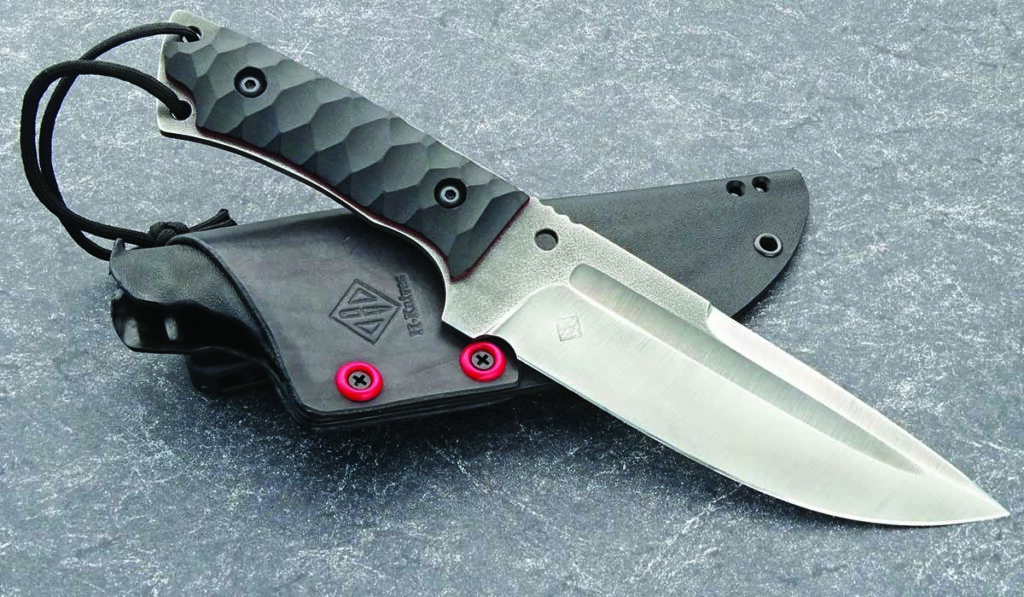

The majority of makers use either stainless or carbon steel. Each offers advantages and disadvantages. Because of the diversity of steel, hunters can select a knife with the steel that best suits their needs.

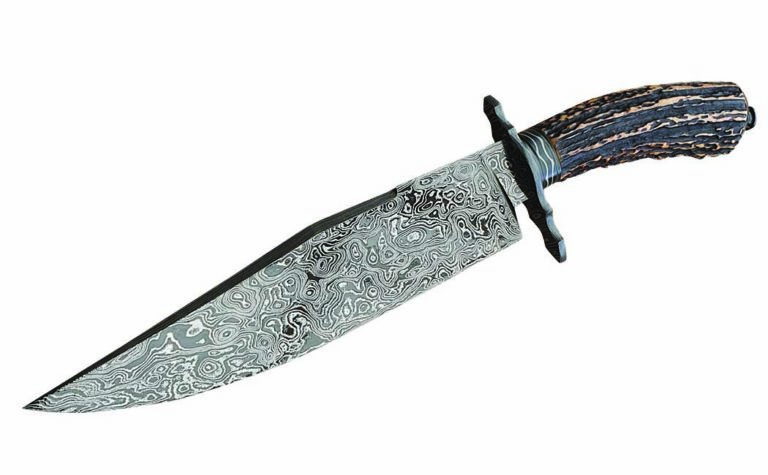

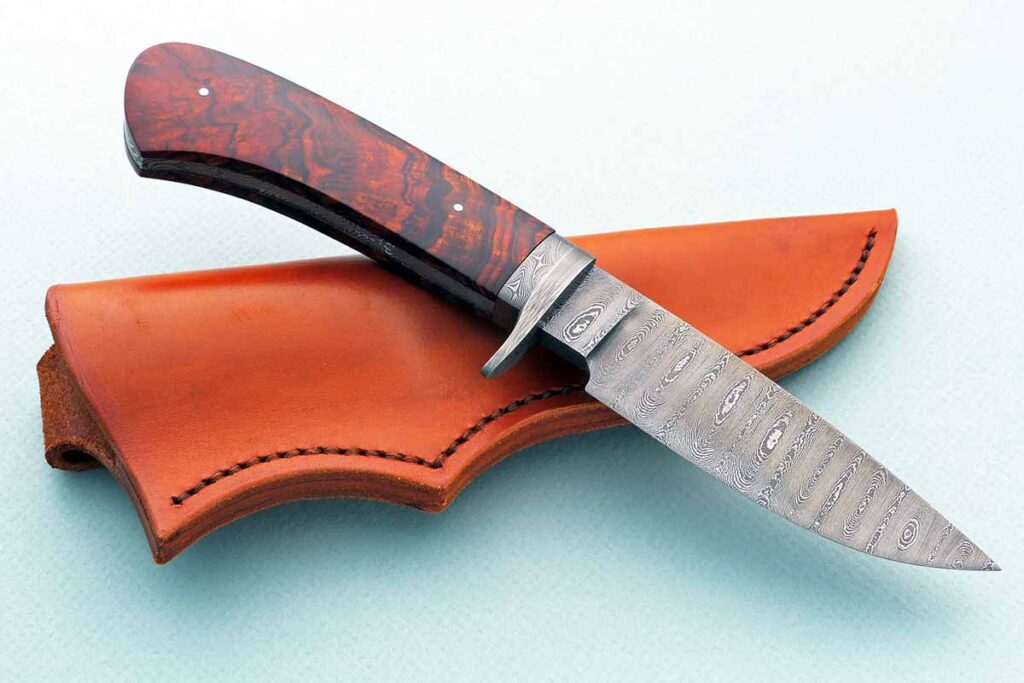

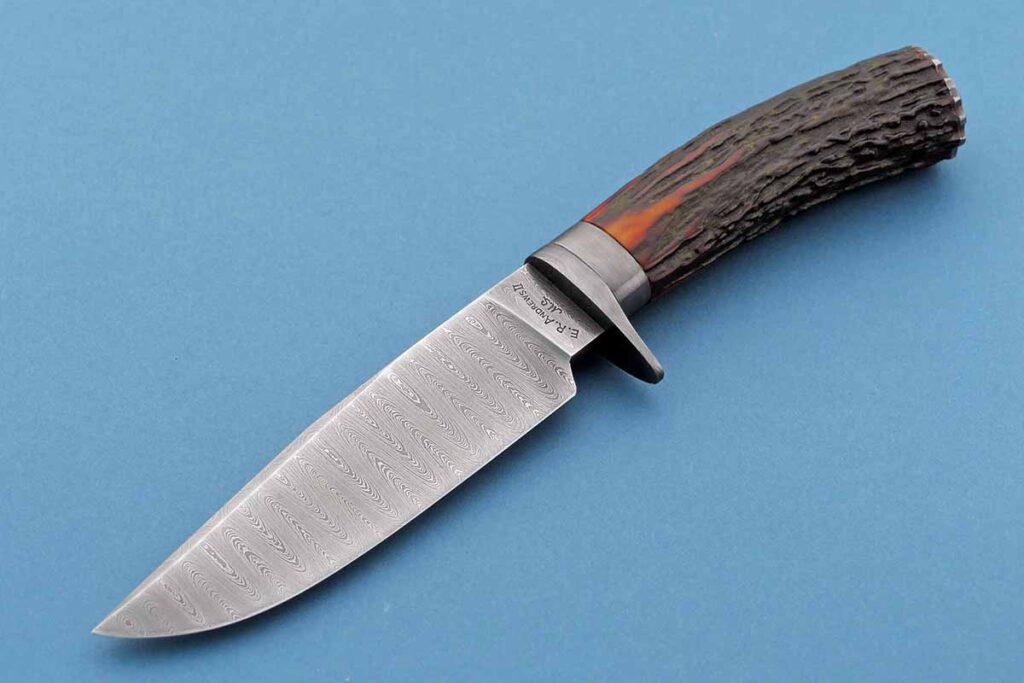

Some hunters prefer patterned damascus steel, such as the ladder pattern of the damascus hunter by ABS master smith Russ Andrews (see accompanying image). Some hunters indicate the damascus blade’s distal tapering and differential heat treatment give the knife a better edge-holding capability. Others prefer steel of a san-mai construction as in the knife of ABS journeyman smith Dan Lewis. By forge welding more malleable steel onto either side of a harder steel, san-mai provides the blade with more structural integrity without sacrificing its ability to hold an edge.

As you can imagine, creating these steels takes additional time and is an added expense. The steels can add anywhere from $150 to $400 to the knife’s cost.

Custom Hunting Knives Handle

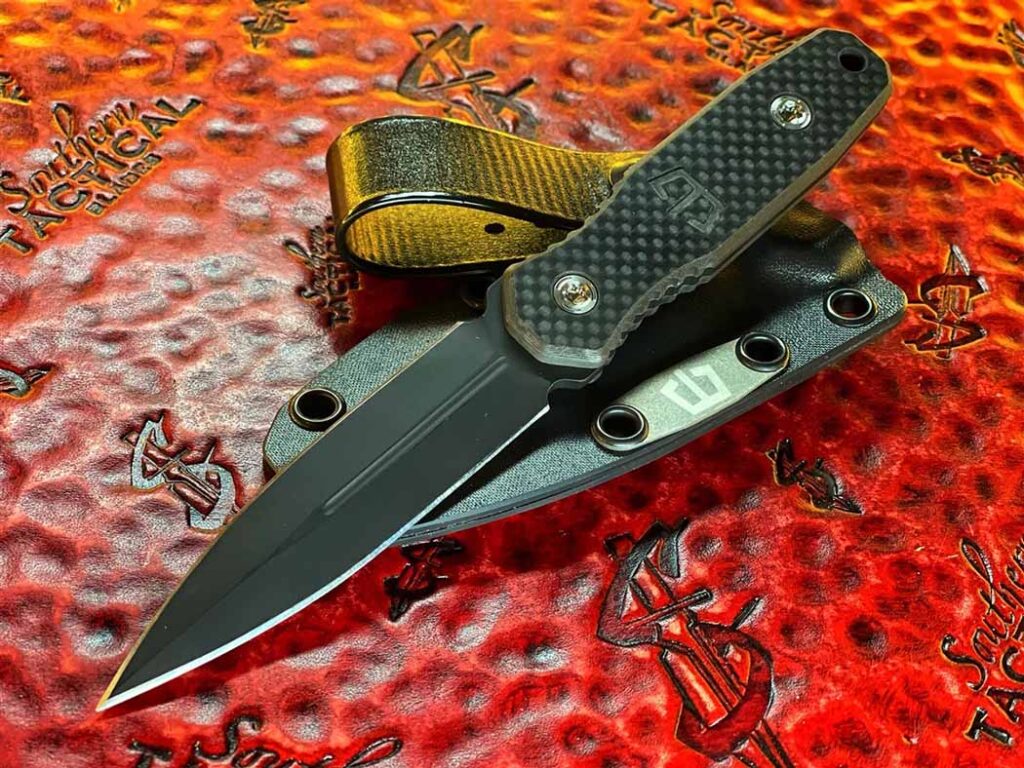

The handle material varies from natural to such synthetic(s) as G-10, carbon fiber and Micarta®. Natural handle materials are even more diverse, including ivory, antler/horn, wood, mother-of-pearl and bone. The advantage of synthetics is they are not subject to the effects of weather and temperature and so do not shrink and/or expand. Also, Micarta and G-10 are less expensive than some natural handle materials.

Natural handle materials can give your knife a unique look, making it stand out from other knives. Ivory, predominantly mammoth or ancient walrus ivory, is among the most distinctive and expensive handle materials used on hunting knives. Mammoth ivory comes in the form of scales and can cost anywhere from $100 to $250. Ancient walrus ivory costs are largely determined by the color(s) and condition. Prices generally range from $200 to $400.

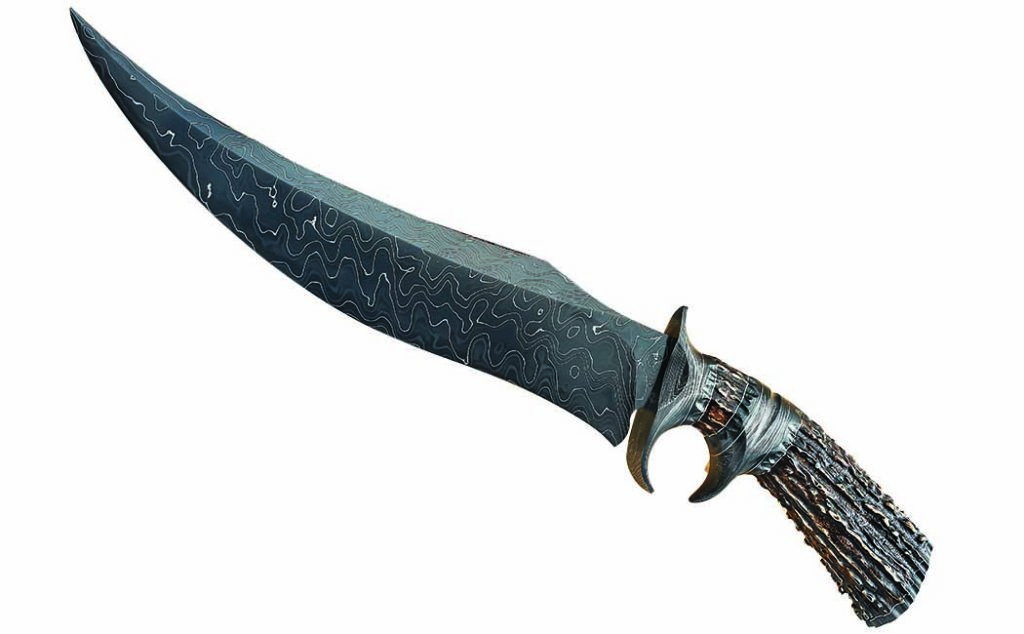

Antlers and horns of all types have been used as knife handles from the onset of knives being built. The most commonly used antler on custom hunting knives is Sambar stag. In addition to its classic look, the natural lands* and grooves of the antler will contour to your hand, giving you a better grip when using the knife. Stag’s demand and lack of supply over the past 15 years have driven the price up considerably. You can expect to add $125 to $175 to the cost of the knife for an excellent piece of stag.

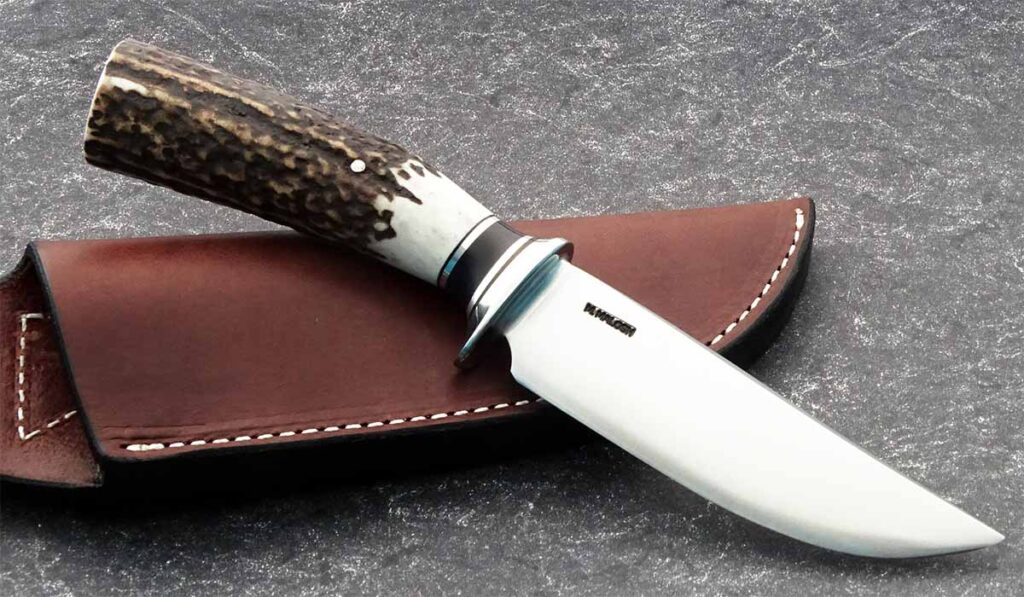

Watching the price of stag increase encouraged me to look at other members of the deer family. One such member is the elk. It has many of the same characteristics as the stag antler, such as the natural lands, grooves and coloring. However, the price is considerably less than stag—around $50. The Elk Hunter (see accompanying image) by Mike Malosh gives you an idea of what an elk antler looks like on a custom hunting knife.

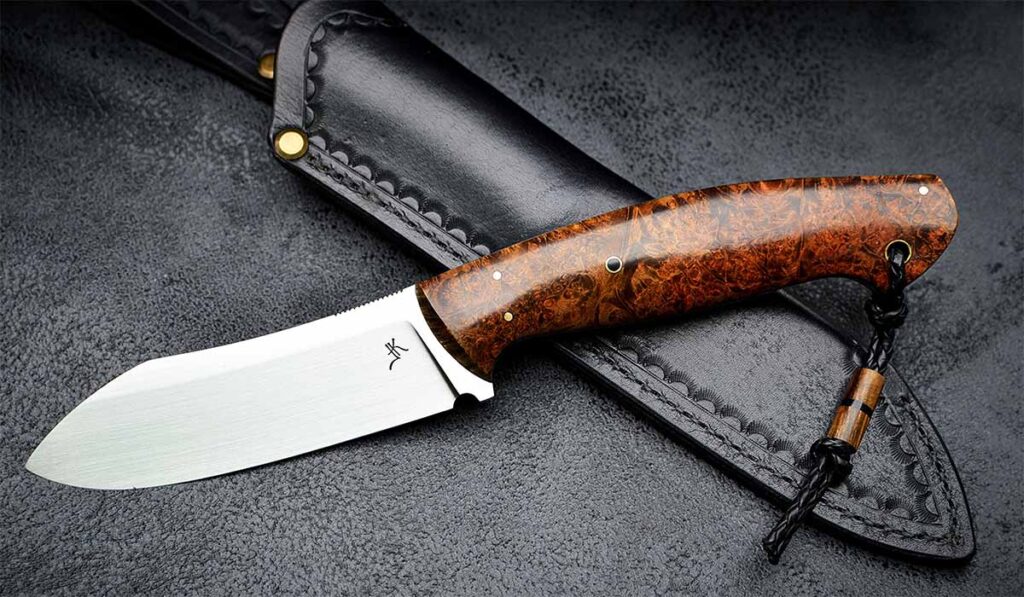

Wood is also a favorite handle material for both makers and collectors. Talk about diversity—wood offers just about any color you could want. Now, with the wood stabilization process commonplace, you eliminate most of the adverse effects of weather on the natural handle material. The price point for wood ranges from $5 to $50 to $75 for scales or a block of desert ironwood or koa. The damascus hunter by ABS journeyman smith Wess Barnhill features a beautiful set of desert ironwood scales. Its range of colors helps ironwood find its way to many knife handles.

Walnut is a hardwood favored by makers such as ABS journeyman smith Luke Dellmyer. It is a very stable, attractive wood that costs $30 a block. Another natural handle material I like, but you don’t see much, is stacked leather washers, as on the Mike Malosh Bear Hunter. One advantage I found with stacked leather is that, over time, the handle material will conform to your hand, providing you with a custom grip. You can expect stacked leather to add about $30 to the knife’s cost.

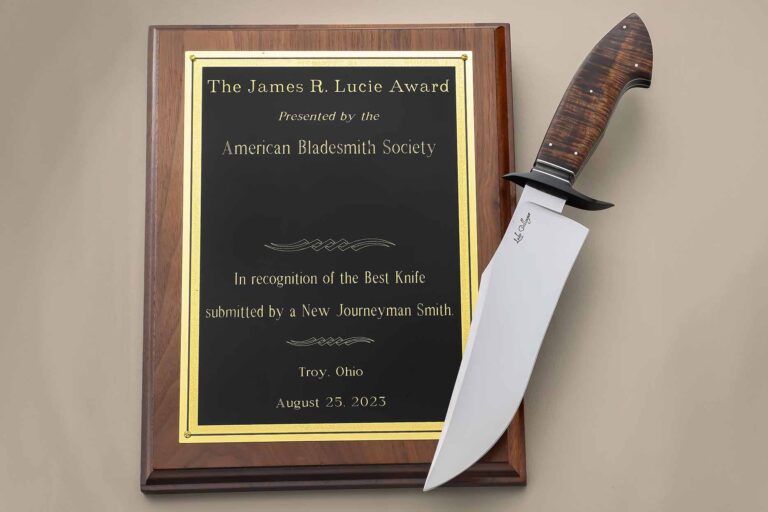

What Makes A True Value

As a professional custom knife purveyor, I offer prices based on my conversations with suppliers and makers and the materials I have bought over the years. As you know, everything gets more expensive, so prices may vary. The makers’ ability to combine the materials to create functional and aesthetically pleasing knives comes from years of honing their skills in their shops. Once you understand material pricing and can differentiate the skill levels of the different makers, you will realize that this is where the true value lies.

*Like on the inside of the barrel of a firearm, lands are the raised part of the antler and the grooves are the recessed part.

Check Out More Outdoor Knives:

- NESSMUK KNIFE: OPTIONS IN THE ALL-AMERICAN OUTDOOR KNIFE

- BEST TOMAHAWKS: OUR TOP HAWKS FOR BACKWOODS TO BATTLEFIELDS

- BEST BUSHCRAFT KNIFE: WHEN STEEL MEETS THE WOODS

- BEST EDC FIXED BLADE KNIFE: A CUT ABOVE THE REST

- BEST CAMP KNIVES: OUTDOORS DO-ALLS