When it comes to custom knives, the best utility hunters have many of the features outlined herein.

Countless articles have been written about hunting knives. Primarily, the stories discussed which knife is best for which game.

The two main features that get the most coverage are the blade-style/shape and the length. The knife referred to commonly as the hunter is more than likely a utility hunting knife.

No matter where you are, if you are using a guide—hunting or fishing—more than likely your guide is the one doing the dressing of the game. Chances are, he is using a utility hunting knife with some of the following features.

Blade Steel

If you ask 100 people what the best steel is for a hard-use field knife, you probably will get at least 50 different answers. Why? End users are very loyal to a steel that has proved itself in the field.

Steels are made primarily for commercial applications—very few are made specifically for knives. Knife blades have been made from saw blades, files and even railroad spikes. If the steel has enough carbon and can be hardened to hold an edge, somewhere in the past several hundred years someone made a blade of it.

The two primary choices for blade steel are carbon and stainless. Each has its pros and cons. Stainless steel’s biggest advantage is that it is rust resistant, meaning it will require less maintenance. Stainless is not code for “no maintenance.” Yes, stainless steel will rust.

Carbon steel requires maintenance. Many things will make carbon steel rust, several examples being the blood from the game that is being processed and some types of vegetation, including vegetables. However, the rust can be held to a minimum or eliminated simply by cleaning and oiling the knife after use. Keep in mind that storing your carbon steel knife in a leather sheath can also cause rust, especially a wet blade, as the tannic acid used to process the leather can cause rust spots.

While carbon steel can rust, it does have advantages over stainless steel, including two if the blade is forged. First, a number of bladesmiths forge distal taper into their carbon steel blades. The taper removes weight from the blade, thereby making the knife lighter in weight and thus easier to carry and manipulate. Second, carbon steel blades can be differentially heat treated to give them a hard edge for sharpness and a softer back for malleability, the latter resulting in a blade with greater flexibility that is much more likely to bend rather than break under high stress.

The steel you choose for your utility hunting knife should be one that can be sharpened in the field and fit the requirements for what you want your knife to accomplish. Remember—it is always best to resharpen your knife before it gets dull!

Handle Material

If you are looking for a group of custom knives that have diverse handle materials, utility hunting knives lead the way. Synthetics, wood, ivory, bone, antler, mother-of-pearl and others—you name it, utility hunters have it.

When many outdoorsmen dress their knives to impress, they want stag. Unfortunately, stag is experiencing two things simultaneously, and neither is good. Because of lack of supply, the quality is going down and the price is going up to the point that the ancient ivories are now becoming an alternative. After talking with knifemaker Mike Malosh at BLADE Show 2021, I have started to order some hunting knives with elk. While not as popular as stag, it is a great handle material and has a nice look.

My experience in the field has made me a true believer in synthetic handle materials. The two most popular are Micarta® and G-10. Canvas Micarta is my personal favorite. As the name implies, there are bits of canvas included when the Micarta is made. This gives the handle a little more grip when wet. Westinghouse Micarta is gaining in popularity. Often it’s referred to as vintage or antique due to the fact most of it was made before 1960.

Carbon fiber is five times stronger than steel, twice as stiff and lighter in weight. This gave rise to numerous commercial applications, eventually finding its way into the custom knife market. Initially used by custom makers for scales on folders, you can now find them using it for fixed-blade handles, too.

The advantage of synthetics over natural handle materials is synthetics don’t shrink and, for the most part, are impervious to the elements. That said, natural handle materials can dress up a knife.

Guards

For the most part, integral guards are utilized as a quicker, less expensive way to make knives. Most are simply squared off to give the illusion that they are somehow protecting your index finger/hand. I learned the hard way that such a guard is not meant for hard work. If you are going to use a knife with this type of guard, wear a glove.

Most custom utility hunters have a single guard with some amount of curve built in to give you a better handle ergonomic. Additionally, it will provide some protection for your index finger/hand. The primary metals used for such guards are brass, nickel silver and stainless steel. While brass is a favorite among factories and new custom makers, the biggest problem is it is soft and can be easily nicked or cut, giving the guard a sharp edge or corner which can dig into your bare hand. Stainless steel guards provide the best protection and least amount of maintenance for your knife.

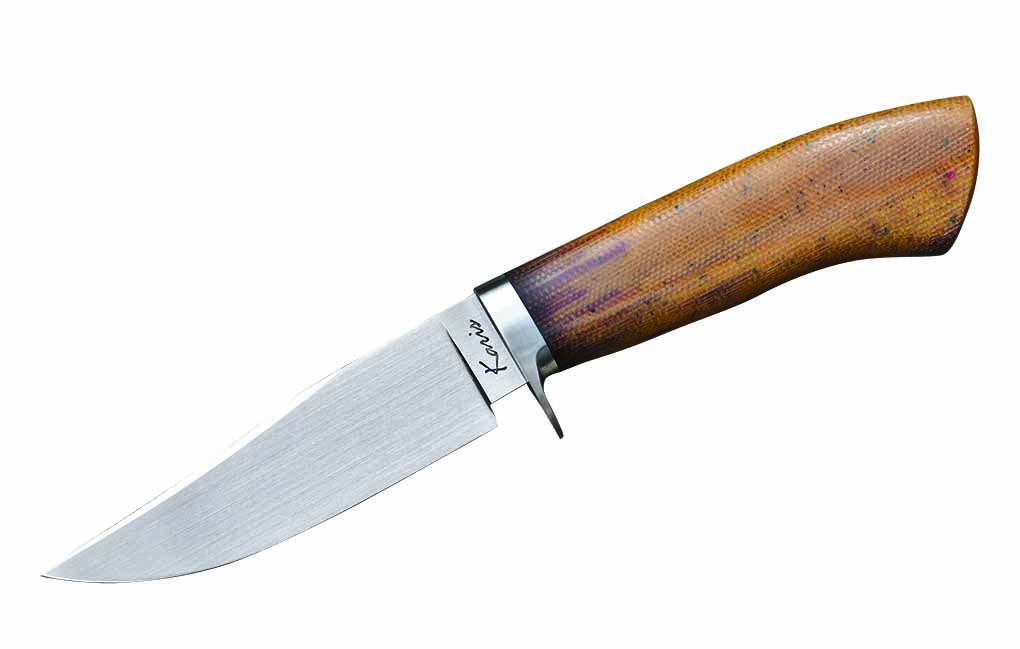

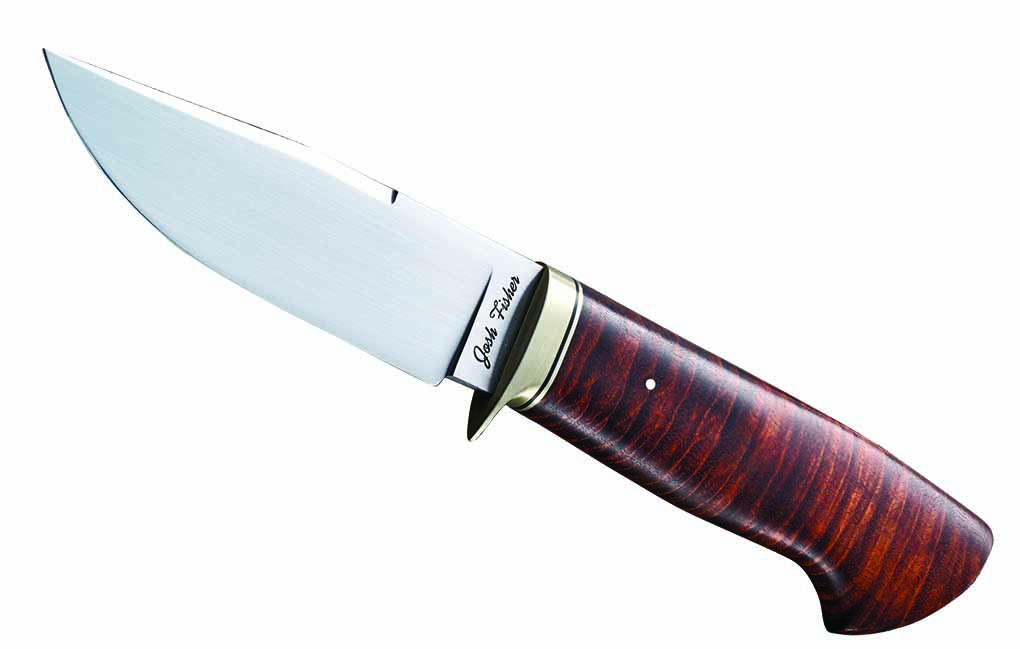

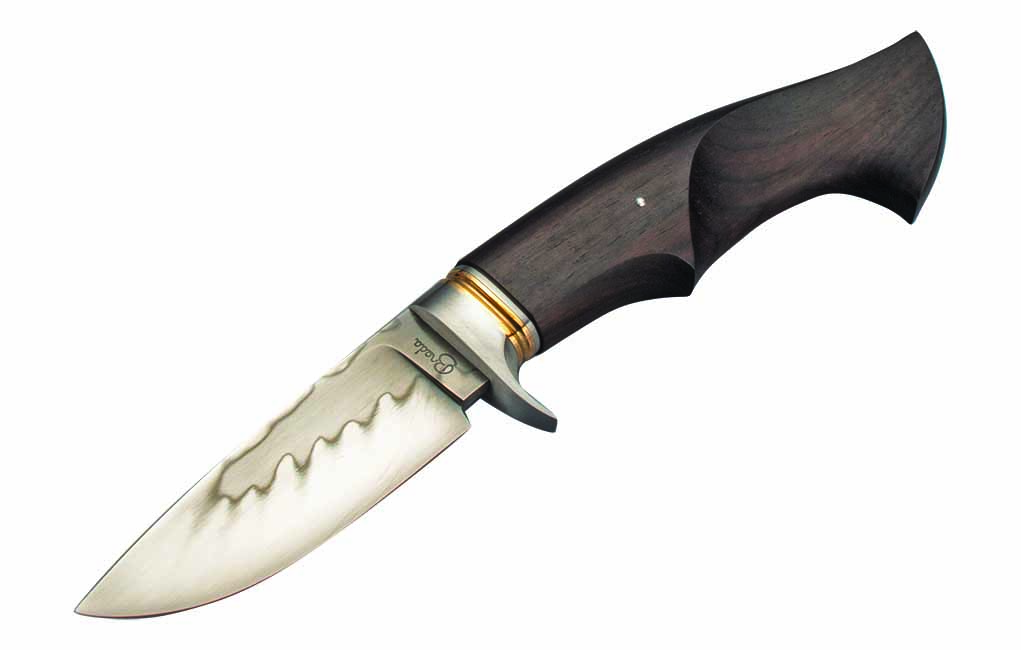

Ideal Sizes

Having judged custom utility hunters at the BLADE Show for over two decades (page 42), I can tell you there is no one ideal size. That said, most of the judging competition winners feature a blade between 3 7/8 and 5 inches long. (For the makers reading this, please do not submit your 10-inch bowie or 2-inch miniature in this category for judging.) Among the accompanying images for this story are three past winners of the category at the BLADE Show. Note the differences and similarities. In addition to dimensions, the importance of handle ergonomics cannot be overstated. Most handles will feature some kind of contouring and generally will be between 4.5 and 5 inches long.

Sage Advice

The custom utility hunting knife will be a workhorse in the field. Consider the factors I have outlined before you buy one. What will you use it for primarily? What size handle is best for your hand? Will you be able to do the maintenance required for the blade steel? Can you sharpen the knife in the field and, if not, will you be able to practice how to do so before you get there?

I prefer a 5-inch blade as my experience has taught me that a big blade can do little knife chores, but not the other way around. As my 7th-grade shop teacher always said, “Use the right tool for the job.” Sage advice!

Raise Your Knife IQ:

- 4 Very Different Versions of the EDC Folder

- 4 Awesome Linerlock EDC Knives

- Modern Tactical Knives

- Custom Chef Knife: The Kitchen Integral

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.