2019: An Important Anniversary

This year marks the 75th anniversary of many major battles that turned the tide for the Allies in World War II. D-Day, Bastogne, Anzio, Monte Cassino, the Leyte Gulf and more are forever etched in the minds of many millions of people. Yes sir, 1944 was a very bad year for the Axis.

For those who fought in those titanic struggles for freedom, 2019 designates the last of the major anniversaries they will see. Most of whom are at least 90 and older today, they obviously won’t be around for the centennial celebrations in 2044. Of course, many of the rest of us won’t as well, but then we didn’t serve in “The Big One,” as Dad liked to call it, either.

In a world that seems bent on forgetting its past, the Greatest Generation members who won that war, both at the front and the loved ones on the home front—including my parents—are unforgettable. No matter race, gender, creed or nationality, the Greatest Generation represents most of what’s good, wise, brave and kind about humanity.

Memories of them are indelible because their deeds are manifest in the subsequent accomplishments and successes apparent everywhere on the globe, including from the bounty of the USA to the remarkable recoveries of two of the Axis powers most devastated by the conflict: Germany and Japan.

Custom Knives & World War II

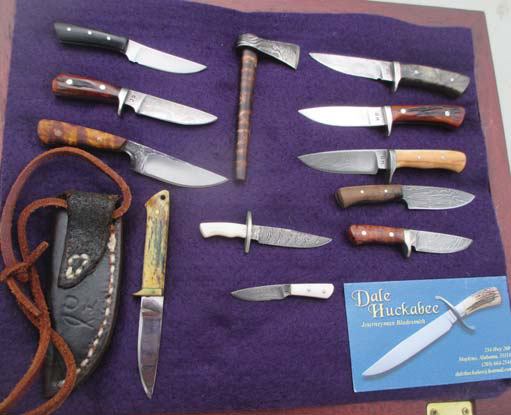

The argument can be made that the custom knife industry can trace its roots to World War II. It was during the war that such knifemakers as BLADE Magazine Cutlery Hall-Of-Fame® members Bo Randall, Rudy Ruana, William Scagel, M.H. Cole and Dan Dennehy made knives for the troops. Dennehy, in fact, both made knives for the troops during the war and also served in it, joining the Navy in 1940 and seeing action in the Saipan, Philippines and other campaigns.

Other well-known makers to fashion knives for the troops during the war included Floyd Nichols, Hoyt Buck, David Murphy, John Ek, Donald W. Moore, Frank Richtig, E.W. Stone, John Nelson Cooper and no doubt more. Each played a role in inspiring what today is the modern custom knife industry.

World War II: Special Tasks Required Special Knives

And then there were those who used knives in the war, people such as U.S. Army Corporal Eugene “Gene” Gutierrez of the First Special Service Force (FSSF). It was the FSSF that carried the legendary Case V-42 dagger and was comprised of specialists in mountain climbing, skiing, demolition and airborne ops.

Wounded eight times in combat, Gene was with the FSSF when it scaled the 10,000-foot-high Monte la Difensa in the Italian campaign and dislodged the occupying Germans.

The climb was “pretty much straight up,” he said of the monumental effort. It took all night under one of the heaviest artillery barrages of the war, but the Forcemen made it up the mountain and routed the enemy. Later the FSSF was inserted at Anzio, where they pushed the Germans back again.

According to Gene, the Forcemen also were specialists in psychological warfare. While on night patrol they would paint their faces black and, after dispatching Germans, leave notes on the vanquished enemy bodies that read, “The worst is yet to come.” The Germans who found the notes nicknamed the Forcemen the Black Devils, aka the famous Devil’s Brigade.

Ninety-eight now, Gene is one of the last of a rapidly vanishing breed. The surviving Forcemen get together for reunions when possible, and Gene has served as the president of their association twice. They are among the leading members of the only generation that is truly unforgettable.