Largest class as HOF honors living and deceased legends.

The BLADE Magazine Cutlery Hall of Fame® is proud to announce its new inductees for 2025: Harvey Dean, Stanley Fujisaka, Rick Dunkerley, Dr. James Lucie, Alfred Pendray, James Schmidt, and Daniel Winkler and Karen Shook.

In a procedural change new for this year, the Hall of Fame has expanded the number of annual inductees from three to seven, the latter including three living and four deceased individuals. The team of Winkler and Shook is counted as one inductee. They, along with Dean and Dunkerley, are this year’s living inductees, with the balance being the deceased ones.

The new Hall of Famers will be formally inducted, including the posthumous inductions of the deceased members, during BLADE Show 2025 June 6-8 at the Cobb Galleria Centre in Atlanta. The induction ceremony will commence the Saturday morning of the show, June 7, at 8 a.m., and will include a breakfast in the Kennesaw Room of the show’s host hotel, the Renaissance Atlanta Waverly. Tickets are required in advance and are limited. For ticket information email [email protected].

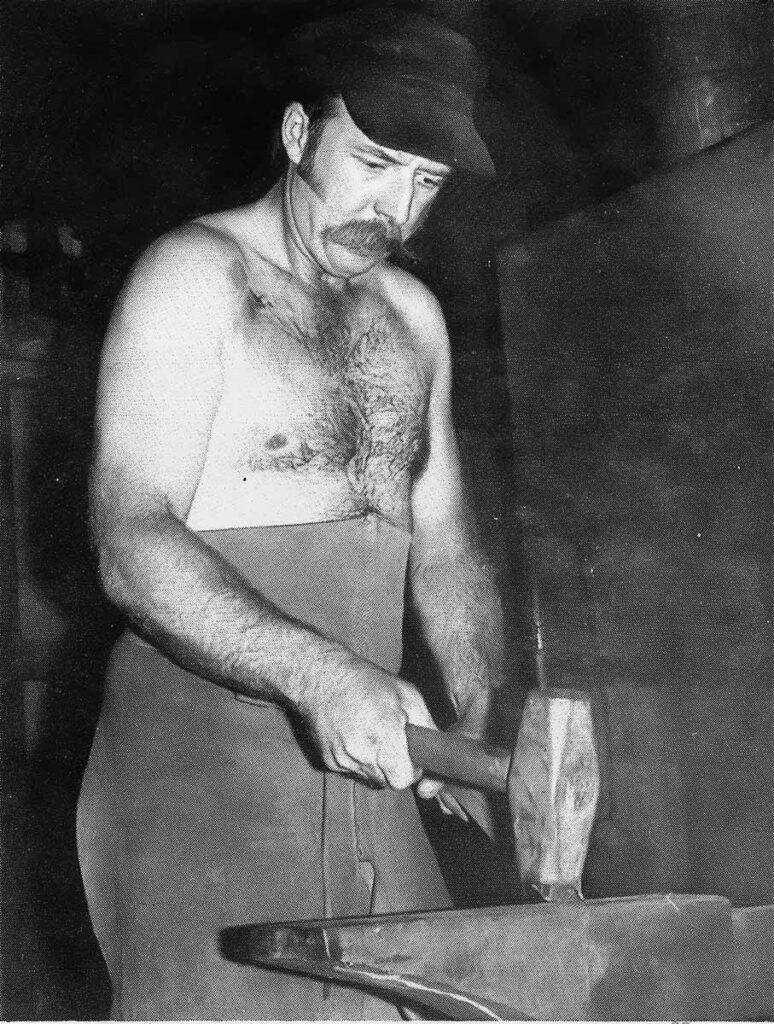

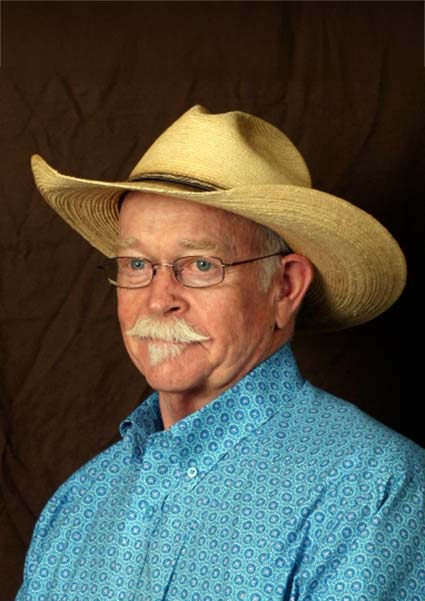

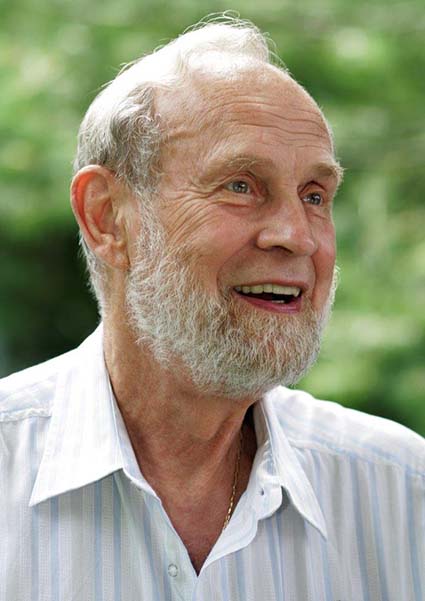

Harvey Dean

According to a nominator, “Harvey Dean earned his American Bladesmith Society master smith rating in 1992 and since then has taught an impressive number of students the art of bladesmithing. He became a member of the ABS Board of Directors in 2004 and served four years with distinction as ABS president from 2015-19. He continues to serve on the ABS board today. He was inducted into the ABS Hall of Fame in 2016. He has won an impressive number of judging awards for his knives, including at BLADE Show Texas, multiple times at the BLADE Show, from the Antique Bowie Knife Association and others. His knives have earned him membership in the prestigious Art Knife Invitational, limited to 25 of the world’s top knifemakers by a vote of the member makers.

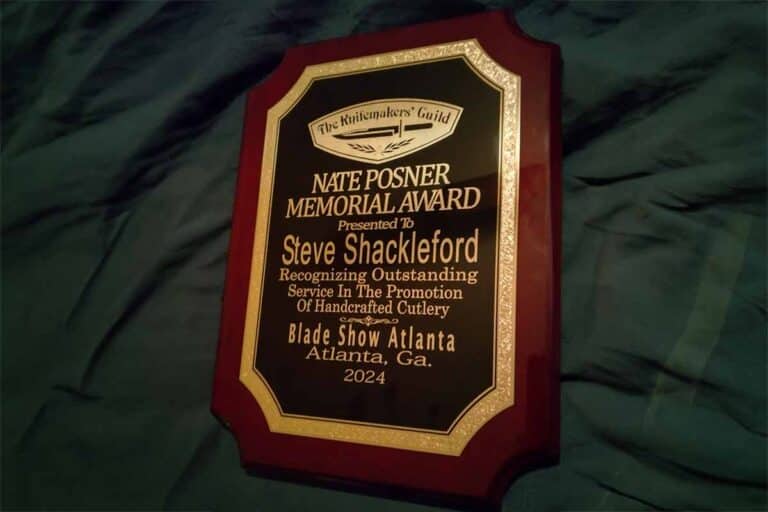

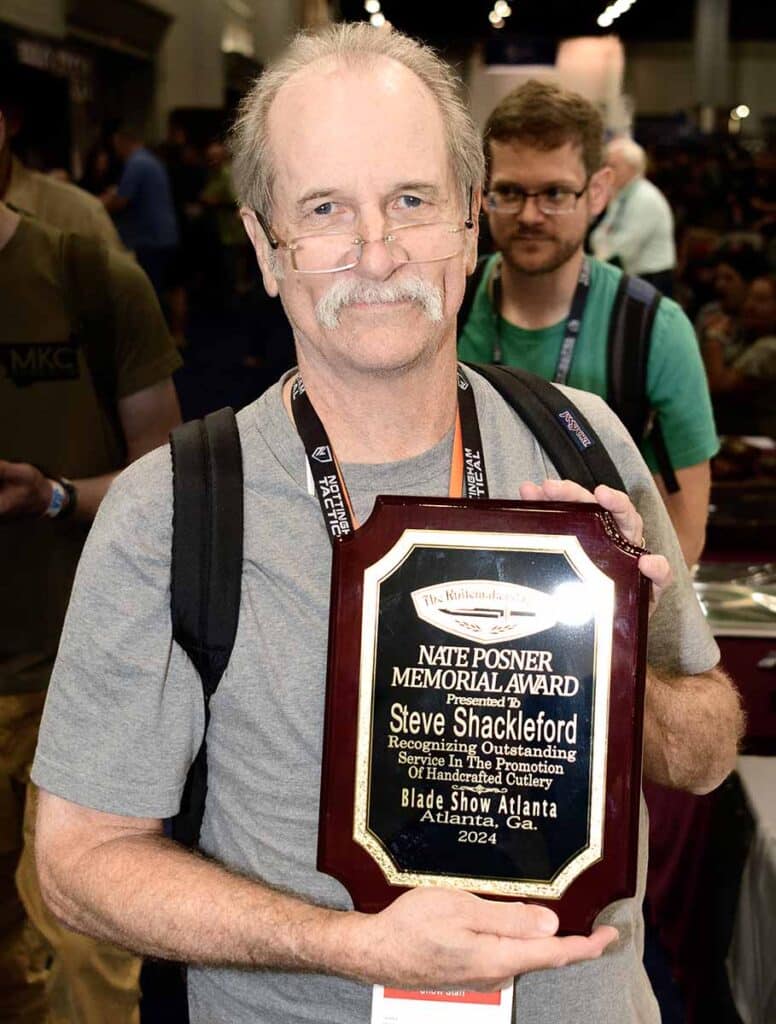

He is a marvelous bladesmithing teacher, a master leader, a master administrator, and a master ambassador for the forged blade.” Along with award-winning knifemaker Johnny Stout, Harvey coordinated two annual knifemaking seminars in New Braunfels, Texas, for a number of years. He has also passed the knifemaking torch to his son Dillon, who creates utility fixed blades of his own. Concluded the nominator, “Harvey is among those named in the book Greatest Living Knifemakers written by Cutlery Hall-Of-Famer Steve Shackleford. I know of no one man deserving of being named to the Cutlery Hall Of Fame more than Harvey.”

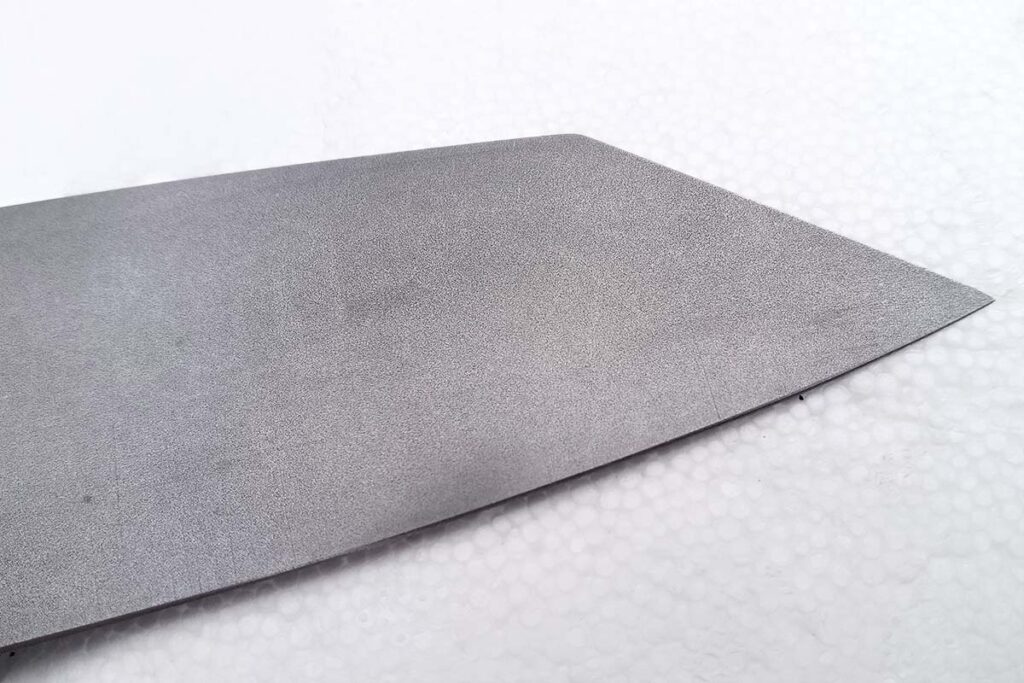

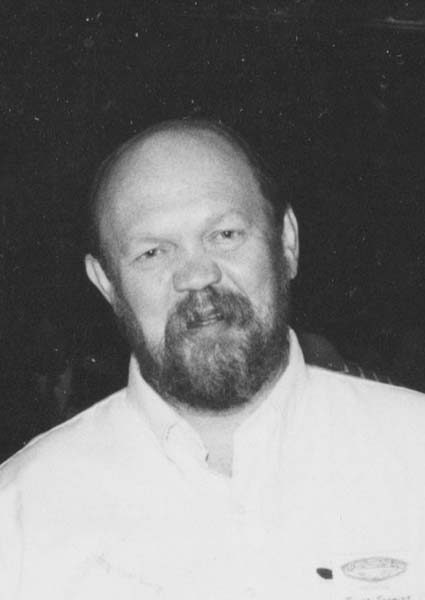

Rick Dunkerley

Rick Dunkerley began making knives in 1983 and started forging them in 1992. He specializes in mosaic damascus folders, winning judging awards for a number of them, as well as an occasional fixed blade. Among others, he’s won judging awards for his knives at the Oregon Knife Collectors Association Show, Montana Knifemakers Association Show, BLADE Show and BLADE Show Texas. His knives have earned him membership in the prestigious Art Knife Invitational, limited to 25 of the world’s top knifemakers by a vote of the member makers. He held many hammer-ins during the ’90s and brought in the best instructors of the time.

Rick has always been generous with information and is an excellent teacher. He’s taught at such venues as the Texarkana College/Bill Moran School of Bladesmithing, the Batson Bladesmithing Symposium, the Massachusetts College of Art, Saskatchewan Western Development Museum, Northern Minnesota Blacksmith’s Association, Northern Rockies Blacksmith’s Association and Western Canada Knifemakers’ Symposium. One of his students, Josh Smith, was the youngest ever to achieve both ABS journeyman and master smith status, and today runs the Montana Knife Co., a factory knife production operation with 105 employees. According to a nominator, “Rick has been on the board of the ABS and does the top shows worldwide. He has paid his dues, is a hell of a guy, always willing to share his knowledge, and makes world-class knives.”

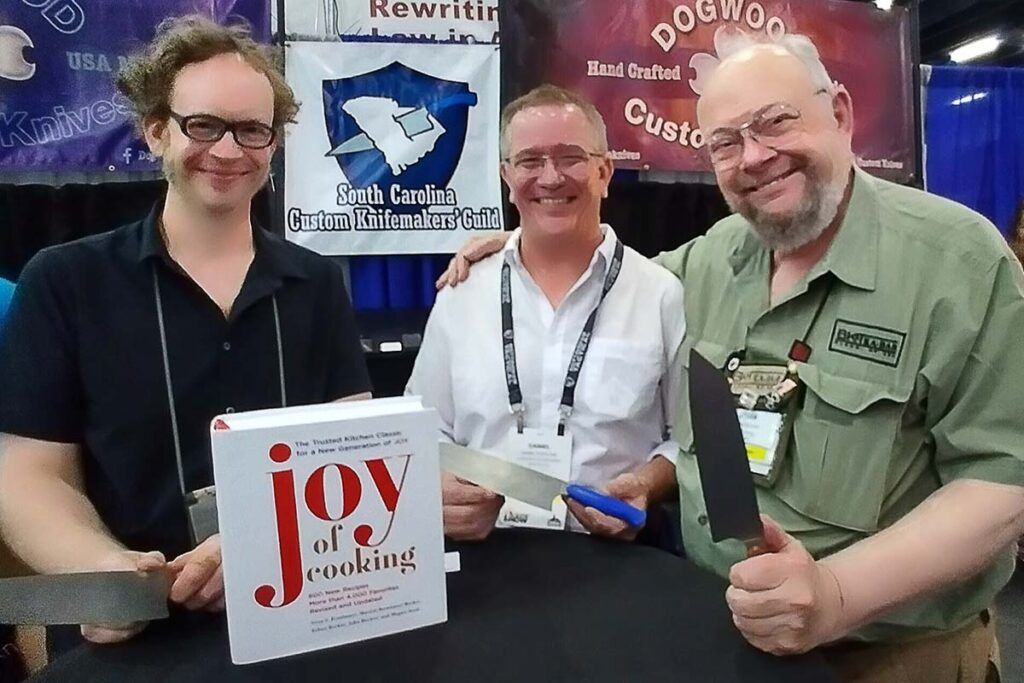

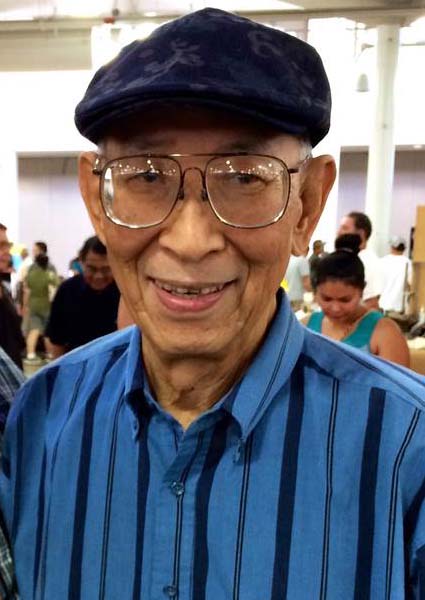

Stanley Fujisaka

Stanley “Stan” Fujisaka went full-time making knives in 1984 and was a prolific builder of award-winning folders and fixed blades. He was a beloved mentor in his Kaneohe, Hawaii, knife shop to a number of Hawaiian and other makers, including Scott Matsuoka, Les George, Cutlery Hall-Of-Famer Ken Onion and many more. Stan played a key role in encouraging Onion to patent his famous SpeedSafe assisted-opening mechanism. As a result and as Cutlery Hall-Of-Famer Dan Delavan wrote, “Ken went on to become the savior of Kershaw Knives.”

Stan also generously assisted knifemakers who fell victim to floods, shop fires, medical issues and more. He was a regular exhibitor at knife shows, donating many knives for door prizes. He collected custom knives and promoted them and the custom industry in general by supporting the Bay Area Knife Collectors Association Show, The Knifemakers’ Guild Show and other knife events. Together with his good friend, Cutlery Hall-Of-Famer Jim Sornberger, Stan co-hosted dinners for knife collectors, area celebrities and others, all of which helped promote custom knives. Finally, when it came to being a goodwill ambassador to the custom knife industry, few if any could rival Stan for his many gifts—including flowers, Hawaiian coffee and boxes of chocolate-macadamia nuts—that he doled out to friends, customers and other patrons at the shows where he exhibited.

Dr. James R. Lucie

According to a nominator, “Dr. James R. ‘Jim’ Lucie was Cutlery Hall-Of-Famer William Scagel’s physician and signed Scagel’s death certificate in 1963. This was the beginning of Dr. Lucie’s Scagel knife-collecting avocation. Scagel is considered by many the father of the modern custom knife. Dr. Lucie discovered his passion for knifemaking in 1990 when he took a class on bladesmithing from Cutlery Hall-of-Famer Bill Moran. Jim was a very talented maker and received several awards for his contributions to the knifemaking community. He assisted other makers often. In 2001, the ABS created the Dr. Jim Lucie Award, which it bestowed on Jim as its inaugural recipient. The award was ‘presented for the unselfish contribution to the preservation of the forged blade. The person receiving this award has gone far beyond the call … and exemplifies the type of person needed to keep … bladesmithing alive.’

Jim also received an ABS Special Service Award in 2002 ‘in recognition of his meritorious and unselfish services on behalf of … the forged blade.’ He also received the ABS Chairman’s Award for Outstanding Service more than once. He was a talented bladesmith, hand-forging mostly Scagel recreations of the highest quality. He improved on Scagel’s designs when it would enhance the knife. Jim dedicated three decades to researching Scagel’s life and collecting his works. Jim’s efforts culminated in Scagel Handmade, a massive hardbound book detailing Scagel’s life, with photos of over 200 knives and other Scagel items. Dr. Lucie hosted a hammer-in in 2001, with over 500 people in attendance. He shared his knowledge of Scagel’s techniques by giving speeches at many bladesmithing events. Late in life, Jim donated his blacksmithing, grinding and finishing equipment valued at $62,700 to the ABS. His actions consistently exhibited honesty, compassion for others and a dedication to the bladesmithing community.”

Alfred Pendray

Alfred “Al” Pendray was a rock to the many bladesmiths he taught and influenced over the decades. “I learned so much from him,” noted ABS master smith Charley Ochs, “not only about knives and metallurgy but also about life and social interaction as a person.” Softspoken but never at a loss for words on the subjects that mattered to him, Alfred possessed an intricate knowledge of many things, including wootz steel, bladesmithing/knifemaking and knife history in general. He had a solid work ethic and led as much or more by example than the spoken word. He knew when to express his views and when not to, a trait sadly lacking in much of today’s discourse. Alfred is co-author—along with Dr. John Verhoeven, a former metallurgical engineering professor at Iowa State University—of articles appearing in eight scientific journals, four bladesmith publications and BLADE on the nature of “genuine damascus,” or wootz steel.

Pendray was granted patent number 5,185,044 on a “method of making damascus blades.” He was a speaker at the Symposium on Damascus Steel at New York University in 1984. He also spoke at the International Conference on Damascus Steel in Germany in 1985 and the same conference in 1992. He lectured at the Imperial College in London, England, in 1992. He joined The Knifemakers’ Guild in 1982 and was awarded his master smith rating by the ABS in 1983. He received the ABS award for the Bill Moran Knife of The Year in 1991 and was elected to the Guild board of directors in 1992. He received the ABS W.W. Scagel Award in 1998 and is a past recipient of the Guild’s Red Watson Award. He served as Guild president from 1998-2004. In September 2001, he was featured on the nationally syndicated Paul Harvey radio show. In 2003, he was inducted into the ABS Hall of Fame.

James Schmidt

According to a nominator, James “Jim” Schmidt was instrumental in raising the level of knifemaking to compete with the finest crafts ever made. Most importantly, he elevated the pursuit to an art but never forgot the meticulous details of the craft. His knives are immediately recognizable and he influenced so many who came after him in meaningful ways. A spectacular book by BLADE® field editor Mike Haskew memorialized the man and his knives: JAMES A. SCHMIDT, The Great Master. A few passages from the book: “As a custom knifemaker he knew few peers. As a mentor and teacher, he was without equal”; “A man of few words, he allowed the results of his skill, precision, and limitless creativity to speak for him. In silent, stunning beauty, they thundered”; and “He welcomed those who were earnestly interested in improving their bladesmithing and knifemaking skills into his shop … and shared with them the light of precious knowledge that he realized should be readily and freely given rather than hidden.”

In the 1970s, along with Jimmy Fikes and Don Fogg, Jim formed the New England Bladesmith Society to promulgate the skills and techniques of knifemaking. Before long the groundbreaking Ashokan Bladesmithing Seminar was born. Jim was a principal organizer, lecturer and demonstrator. He was one of the earliest members of the ABS and one of the earliest ABS master smiths, and a member of the ABS Hall of Fame. He was a constant member of the Art Knife Invitational, a winner of the Red Watson Award from the Knifemakers’ Guild, the Beretta Award for Outstanding Achievement, and many other honors from a number of custom knife shows. In time Jim decided to let someone else win an occasional award and became a judge at many shows. His approach was to be meticulously but fairly critical and always encouraging. He was indeed the ultimate teacher, his profession for most of his life.

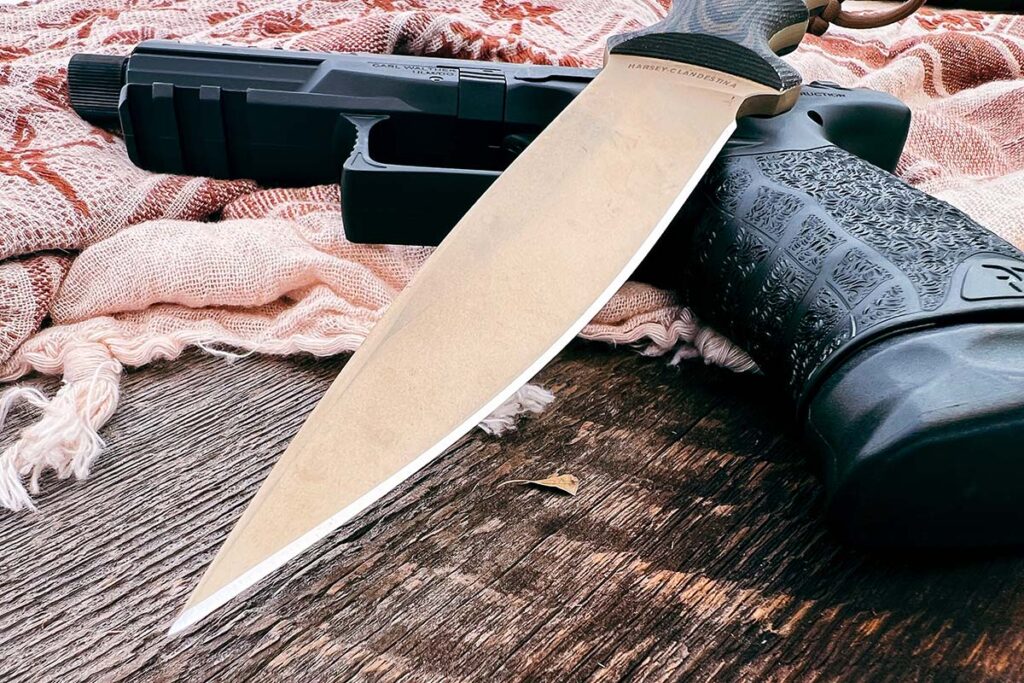

Daniel Winkler And Karen Shook

ABS master smith Daniel Winkler and Karen Shook first made their mark in the world of knives with custom reproductions of historical knives and tomahawks. Daniel made the knives and hawks and Karen made the accompanying authentic period sheaths, and the two became internationally known for their work. Daniel and Karen taught for the ABS for many years and Daniel was in the vanguard of the Society’s early cutting competitions. The two were at the forefront of early American historical arms and their period pieces were among those featured in the 1992 feature film, Last of the Mohicans. In 1994 a Navy SEAL Special Warfare operator asked Daniel to make a tomahawk because there was nothing on the market that worked for the SEALs at the time. According to a nominator, “Karen designed a sheath the SEALs liked and over the years she and Daniel did more special projects for the SEALs, ultimately inspiring the two to form Winkler Knives II.” Added another nominator, Daniel and Karen’s operation “soon became the cutlery armorer of many top Special Ops teams, from the SEALs to Delta Force, and to those of other nations as well.

For many years Daniel and Karen quietly made the knives, axes and sheaths without seeking glory or publicity for their work. In fact, they insisted that their generosity and unselfishness remain a secret among those who discovered it. It was only upon mention of their work in the book No Easy Day, in which the SEAL Team member on the Bin Laden take-down mentioned he was carrying a Winkler knife, that Daniel and Karen’s work became known to the general public. With such demand, they have expanded into a mid-tech operation and from there into that of a cutlery producer.” Today, Winkler Knives has a 35,000-square-foot facility employing one part-time and 28 full-time workers. “Few have transitioned into the changing markets as well as Daniel and Karen,” the nominator noted, “and none have done so with such humility and class.”

See Other Hall Of Fame Members:

- HENDRICKSON, IMELS JOIN CUTLERY HALL OF FAME®

- LORENZIS, RUPLE JOIN CUTLERY HALL OF FAME

- CUTLERY HALL OF FAME USHERS IN THOMAS, TERZUOLA AND SCHWARZER

- KEESLAR AND SORNBERGER JOIN CUTLERY HALL OF FAME®