Tony Bose said if you can make a lockback whittler, you have arrived as a knifemaker.

While the whittler is a classic pocketknife pattern that dates back at least to the 1850s, a variation on the theme incorporating both the lockback and slip joint mechanisms offers a challenge to the custom knifemaker and a delight to the owner of this intriguing style.

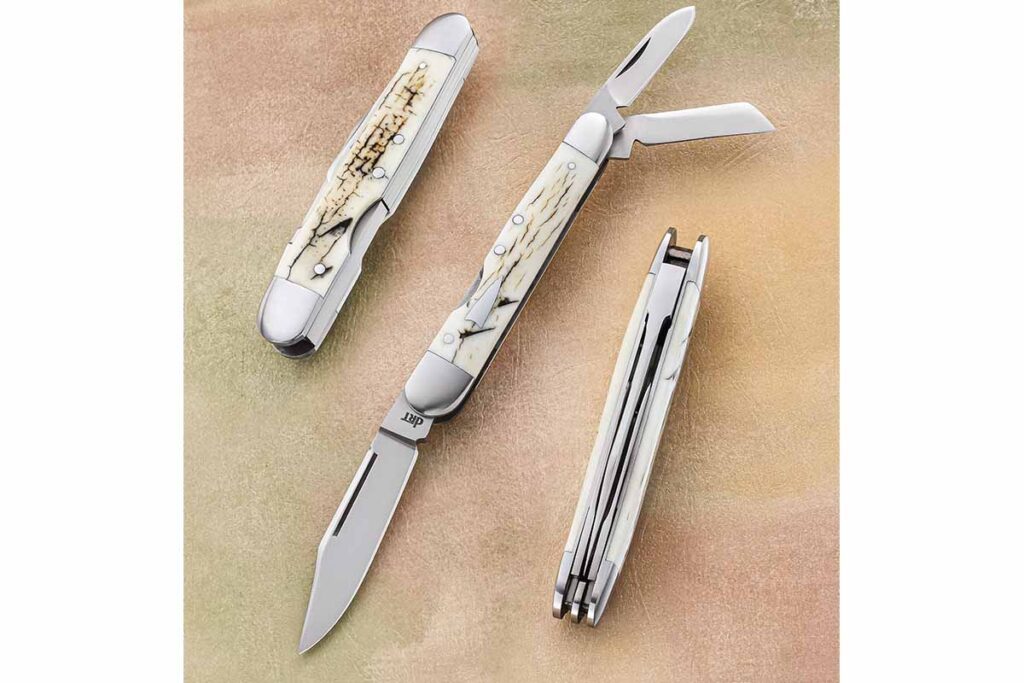

Custom knifemaker David Taber explains his take on the whittler as a three-blade knife with the main blade on one end and two secondary blades on the other. Simple as that. However, from definition to completed construction it’s a bit more complicated, particularly when the lockback mechanism is thrown into the mix.

“The whittler as originally designed was very functional in that the larger main blade is used for making larger cuts and the two smaller blades are for more detailed cutting,” Taber advised. “The knife is necessarily thin by design with the two small blades nestled on either side of the main blade in the closed position, which makes for a slim, pocket-friendly knife.”

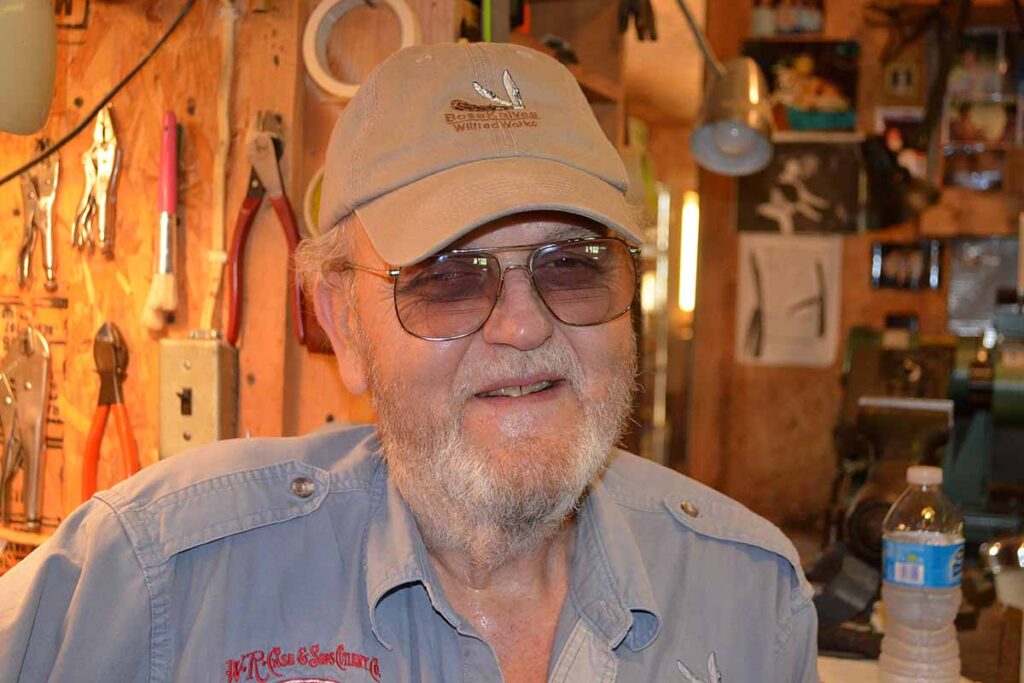

Taber’s rendering of the lockback whittler features hollow-ground blades of CPM 154 stainless steel and a mammoth ivory bark handle. The main locking blade length is 3 inches and his price for a comparable piece would be $2,100. He attributes an early interest in the lockback whittler to comments made by BLADE Magazine Cutlery Hall-Of-Fame® member Tony Bose in a 2008 issue of BLADE® relating to the skill level required to make one.

“I was intrigued and called Tony,” David remembered. “That single conversation started a lasting friendship and started me collecting and eventually making knives. In later years he challenged me to make a lockback whittler and shared his pattern with me. He said, ‘If you can make one of these, David, you will have arrived.’”

Taber took on the task with gusto and through personal experience describes the challenge. “The difficulty, in my opinion, lies in centering the main locking blade in the closed position between the two slip-joint blades at the opposite end without rubbing during function. Equally difficult is balancing the two springs that operate the two slip joints on the one end and the underside of the lockbar on the other end. Think of it like a sophisticated teeter-totter,” he explained. “Care must also be taken to maintain the length, particularly the end that controls the lock tab. It has been my experience that to shorten it even the slightest amount will increase the load deflection rate and thereby make the lock tab not function properly.”

The level of difficulty in making the lockback whittler contributes to its collectability, Taber says, which in turn makes the design rarer in the marketplace. “The typical collector of the lockback whittler is usually aware of the skill required to make such a knife and achieves great satisfaction from owning one,” he reasoned.

MOST DIFFICULT?

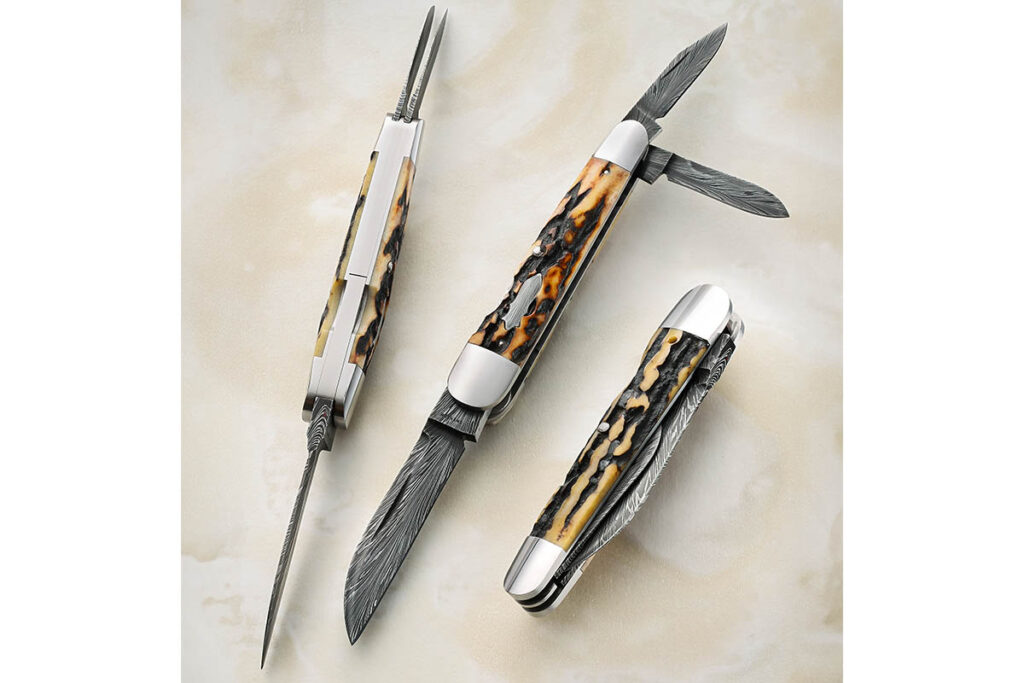

Knifemaker Luke Swenson shares a connection to Bose with Taber. The Case-Bose collaboration effort introduced Swenson to the design. “The blade configuration and the smaller blades being half the thickness of the main blade set it apart from other patterns,” he commented. “Some whittlers have a ‘catch bit’ or a piece of liner material to hold the blades apart at one end so the main blade clears, and some have a tapered wedge, commonly called a splitback. In the case of the lockback whittler, there is a full spacer that rests between the rear slip-joint blades. Also, in a lockback whittler the small blades and spacer are exactly one-third the thickness of the main blade. The main blade locks, and I believe this is for safety and allows for harder use.”

Swenson’s lockback whittler features a hollow-ground 2.8-inch blade of feather damascus forged by Mike Tyre. The fittings are 416 stainless steel and the handle is natural stag. Luke’s price for a similar piece is around $3,000. He describes the lockback whittler as “the most difficult pattern to build, even more so than a six-blade. I believe it isn’t just the combining of elements, but the springs are somewhat tricky in that you have to be paying attention—one false move, or even one over-aggressive pass on your grinder, and you’ll be making new springs. Grinding the small blades isn’t easy and requires a developed feel for getting them right. Very challenging! But if it’s right, the results are magic.”

According to Luke, the construction of the slip joint and the lockback are completely different, at least in the opening stages. Putting the two mechanisms together with tiny parts, delicate springs and narrow tolerances tests the skills of the knifemaker in an extraordinary way. “The blades have to sit in the handle to make their tips sit in the handle,” he concluded, “and yet the nail nicks have to be accessible. That takes time and patience to get right.”

Renowned custom knifemaker Wolfgang Loerchner happened past Swenson’s table at the East Coast Custom Knife Show some time back and asked if Luke could make a lockback whittler. “This was in the March of that year, and we agreed on a BLADE Show delivery in June,” Luke laughed. “Keep in mind I’m an unknown maker, and starstruck doesn’t quite describe what I was feeling. I said, ‘Sure, I can get one built.’”

From there, Swenson went to “The Maestro,” Cutlery Hall-Of-Famer Bill Ruple. “He was quite amused and laughed, a little more than was polite I thought, but he agreed to help me through the process,” Luke recalled. “Like all my slip-joint making, anything I learned to do right was in Bill Ruple’s shop. He was key. I don’t believe I would have made the deadline if he hadn’t helped me. I’d send him pictures, and he’d say, ‘remake this and fit it like this instead.’”

The bottom line for the Swenson lockback whittler is its tremendous appeal. “It is a sleek, streamlined beauty,” he offered. “Like anything Tony Bose decided to do, it is elegant and feels comfortable in the hand.”

COMPLEX SIMPLICITY

When knifemaker Tim Robertson envisions his next lockback whittler project, he knows what he’s getting into. “What truly makes the lockback whittler so difficult to build is the way the springs operate,” he noted. “The slip joint is a standard arch spring pushing down on the blade tang while also lifting up at an equal force on the rear of the lockbar, keeping the blade firmly in position. Too much load on either end loosens the opposite end. In a nutshell, the springs have to be balanced between lockbar function and slip-joint function.”

Robertson has become well known for his lockback whittler proficiency, and two recent examples have won awards. His winners of Best Locking Folder at BLADE Show West 2022 and the 2023 Knifemakers’ Guild Best Multiblade Folder both sport CPM 154 stainless blade steel, 416 stainless frames and stag handles. His prices for similar knives would be about $2,500 each.

With a simple explanation for his foray into lockback whittlers, Robertson remarked, “I just wanted to see if I could do it. The lockback whittler is appealing due to the complexity of the multiple parts and simplicity of design and operation.”

Defining the whittler as a knife with three blades and two springs, Tim commented, “The most common types are the splitback variety with a tapered spacer separating the two pen blades. The reason for the tapered spacer is to allow clearance for the blade to fold into the handle without having to have the main blade thickness increased, and then offset ground for the clearance so that one pen blade falls on each side of the main blade.”

SIDE-BY-SIDE KNIVES

Knifemaker Rhidian Gatrill consulted friend and historian Neal Punchard on the origin of the lockback whittler. In response, Rhidian learned that the earliest examples of it were probably made in Sheffield, England, a major center of European cutlery, and later by German and American cutlers.

“It is a premium pattern and difficult to make, so not many companies took on the challenge,” Gatrill explained. “Some of the early Sheffield multiblade sportsman knives and a few rare jackknives had lockback main blades and slip-joint blades, but they are basically two knives side by side. There’s nothing quite like the lockback whittler. There are a few other pocketknives that have locking main blades and slip-joint secondary blades, but they’re not lockback knives. The electrician knives, for example, have a [locking liner] on the screwdriver blade. And there are pen-blade-release knives where the small secondary pen blade gets pushed in to unlock the main blade.”

Motivation to make the challenging pattern was easy for Gatrill, who won Best Folder at BLADE Show West 2023 for his lockback whittler cleverly named Lockback Rhiddler. “I like interesting mechanisms and figuring out how to make them work,” he related. “I wanted to challenge myself and see how hard it was to make. Plus, I was attending my first knife show ever, which was the Oregon Knife Collectors Association show in Eugene, Oregon, and I wanted to take something that would possibly win an award. That knife ended up winning Best Folder and Best of Show.”

Looking for examples of lockback whittlers that were striking in appearance and function, Rhidian did some research and recalls, “Like most pocketknife makers, I admire the knives of Tony Bose, Bill Ruple, Ken Erickson and other masters that came before me. I traced photos of their knives and read forum posts that give a few tips, and I asked a few questions from other maker friends that have made lockback whittlers.”

That research led to an opportunity to present a lockback whittler interpretation that resonated with the collector community. “I believe knife collectors like them for their rarity, complexity of mechanism, and interesting function of combining the lockback blade with the slip-joint blades,” Rhidian concluded. “They also look cool with the thick tang on the main blade that steps down thinner and tapers to a point. A locking blade is always a little safer than a slip joint technically, so there’s that for the user. Not many custom makers have made them, and those who do don’t make many!”

Read More

- 5 Best Pocketknife Options For EDC

- Best Pocketknife Brands

- 5 Best Pocket Knife Sharpeners

- Best Japanese Pocketknives

- Best Damascus Pocketknives

- 4 Perfect Pocketknives For Women

- Best Tactical Pocketknives

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.

WOW!!

I love Tony Bose!

I’ll have to get my friend to make a knife like this