Natural and synthetic materials are equal parts fashionable and functional.

They complement one another in an easy, seamless union—blade and handle. One without the other means the knife is incomplete, or it isn’t a knife at all.

Along with the search for proper blade steel, appropriate handle material is the second critical element in the presentation, form, and function of the knife itself. Natural and synthetic handles play their roles. They bring utility and aesthetics to the package, and the maker’s choice sets the tone. Availability, cost, and maker’s preference fit into the equation when choosing the right handle material. And then, of course, the intended knife use weighs heavily.

In the end, it’s the eye of the artist that drives the visual element, and the job to be done by the user that directs his or her choice. The handle makes the knife complete.

At Masecraft Supply Company, co-owner Chris Hartman sees the supplier’s role as the facilitator. Never interfering with the artist’s concept, he views Masecraft as a provider of the palette. “We don’t advise what to use,” he reasons. “We are not big fans of, ‘You know what you should do …’ or telling a customer what to use, but more in supplying a wide variety of options to choose from. We are always willing to answer questions about our materials a customer may have, but it’s just not a good idea to advise what is right for them. That’s the maker’s choice.”

Knife Handle Material Trends

With that said, where is the market headed today? What does the landscape look like in terms of availability, trends, and timing?

“The majority seem to be sticking with composite laminates like G-10, canvas and linen Micarta, and Richlite,” Hartman says. “Natural materials like bone and horn seem to be in a continuing decline. Exotic woods still do well, but availability and pricing have become issues over the last two years.”

John Cammenga, vice president of operations at White River Knife & Tool, Inc., deals primarily in synthetic knife handle materials. He indicates that knifemakers who build hard-use models often lean toward durable synthetic handles and that the laminate trend holds up there as well, particularly with material available in a variety of colors.

“The majority of our handle materials are synthetic,” Cammenga says, “and this is primarily due to stability and longevity. But many look great as well. Multi-color layers of fabric bonded with phenolic or polyester resin can have the look of wood, yet last much longer. Additionally, many of these are tackier when wet, giving the user additional hand purchase in tough weather or when processing game. Carbon fiber and G-10 are available in an ever-expanding array of colors and patterns and almost bulletproof when it comes to wear and tear.”

Choosing Knife Handle Material

The choice of materials, Cammenga explains, comes directly down to the proposed use of the knife. For hunting, fishing, camping or bushcraft, White River almost always recommends synthetic handle material. However, John still gives a nod to personal preference. Some users simply must have a natural handle, and the aesthetic factor comes into play there.

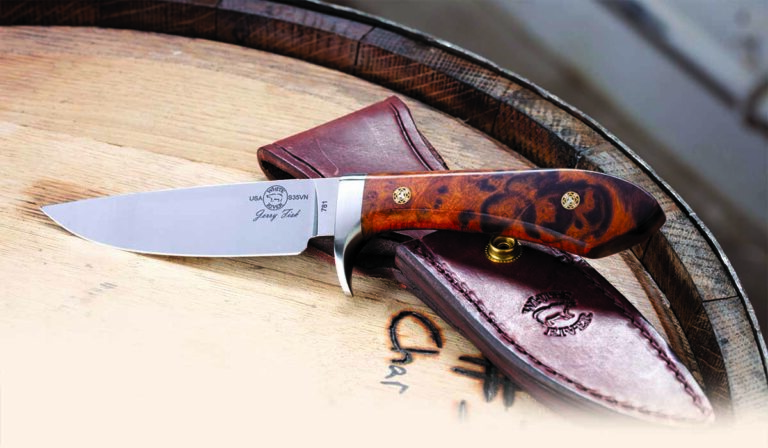

“It’s hard to beat the beauty of a highly figured burl!” he comments. “Some, such as desert ironwood burl, are not only beautiful but also extremely tough.”

Tom Krein is an experienced custom knifemaker who worked for the great Bob Dozier and ran the custom shop for A.G. Russell Knives before embarking on his own venture during 30 years in the business. Making small utility and hunting knives primarily, he agrees that handle material choice relates to a few simple concepts.

“It comes down to the customer’s needs, willingness to care for the knife, aesthetics, and budget,” Krein relates. “Natural materials should hold up nicely with proper care assuming everything goes according to plan. Sometimes stuff happens—a knife falls into a sink of water, or it starts to rain while hunting, or your knife gets lost in the yard for a week. Synthetics hold up better when stuff goes south. For customers, I recommend getting what you like and learning how to take care of it. For knifemakers, I suggest picking the mind of another maker who uses the material you want so you can learn how to use it. Overall, we are a helpful bunch of people.”

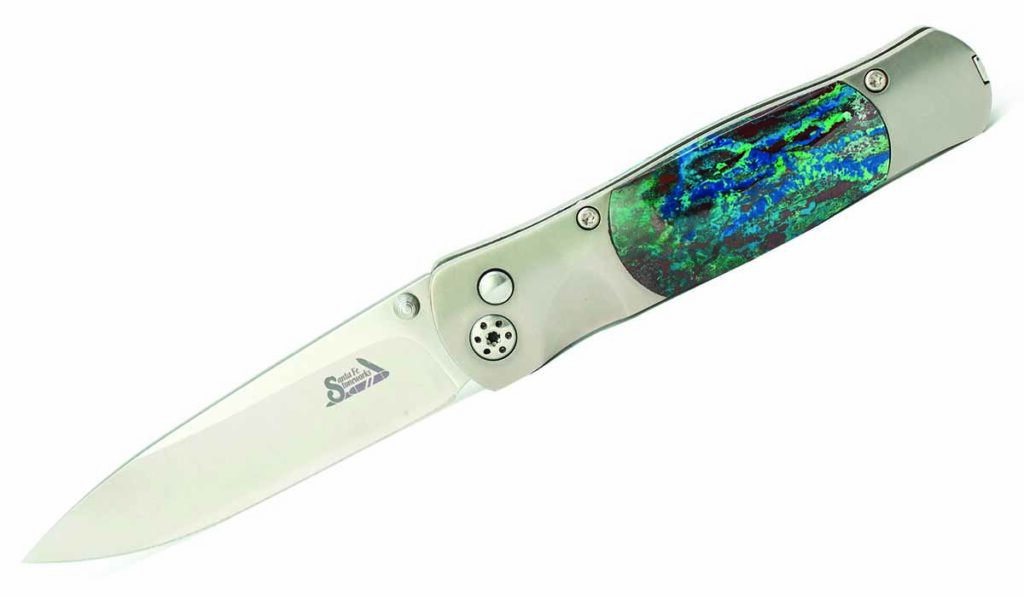

Traditional handle materials and their innovative, eye-popping counterparts coexist at Santa Fe Stoneworks, a provider of materials to the art knife market since 1978. Santa Fe not only affixes those materials to its own knives, but also provides the service for Spyderco and Kershaw while doing private label work as well.

President Bill Wirtel leads the family business, and the company’s roster of natural handle materials includes the best of the best. “We work with factory knives and apply gemstones, exotic woods, shells like gold- and black-lip pearl, and fossils such as woolly mammoth tooth, tusk, bone, and petrified dinosaur bone,” he remarks.

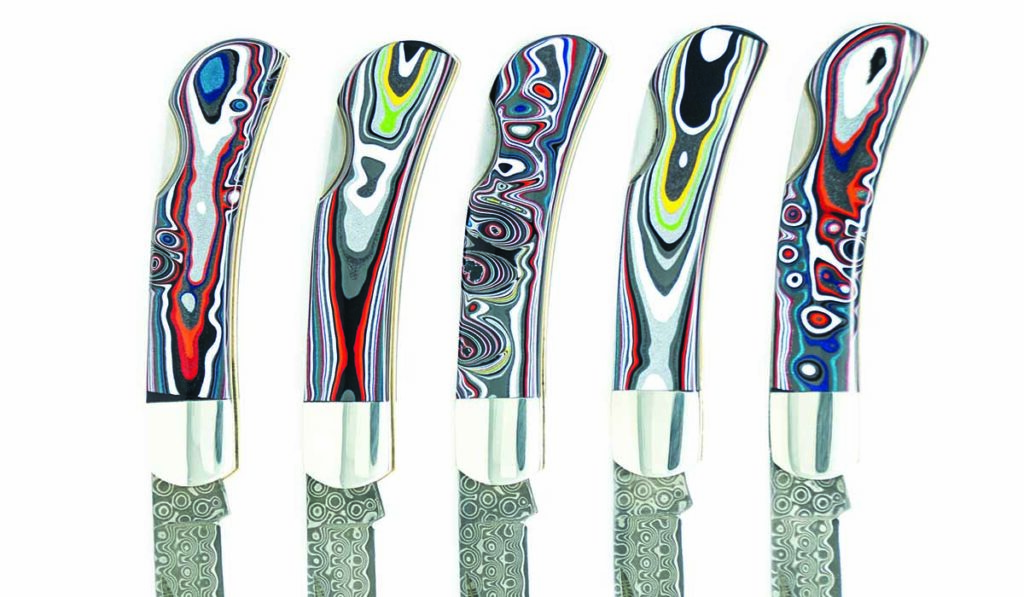

As for Santa Fe’s synthetics, Fordite, a car paint overspray, Surfite surfboard overspray, and a cholla cactus-like material that is made in the shop have found favor with makers and buyers alike.

Material Mash Up

“We are looking for design and color, so we mix natural with manmade stone and epoxies,” Wirtel explains. “Our fossils are all stabilized so they work great for a handle material. We see hybrid materials gaining popularity as they provide the best of both natural and composite materials. Fordite and Surfite have been selling well. Our synthetic cholla cactus line that we make here, stabilizing it with different colored epoxies, is becoming a big seller as well. We also have mammoth tusk fusion. This is stabilized fragments of mammoth ivory that are fused together under immense pressure. The result is a beautiful and hard composite that is densely packed with mammoth ivory.”

Fordite is an interesting option that comes from a surprising source. Also known as Detroit agate or motor agate, the material consists of pre-1985 automobile paint that hardened sufficiently to be cut and polished. It formed from enamel paint slag, which built up over the years in layers on the tracks and skids where cars were hand spray-painted. The buildup hardened in ovens intended to cure the paint on car bodies. After so much of that buildup, the brightly colored and layered paint had to be removed. Its allure caught on with some autoworkers who brought pieces home with them. From there, the beautiful Fordite material, which can be cut and polished into a spectacular look, found its way onto knife handles.

The Masecraft perspective is somewhat dictated by availability. “Sambar stag is not coming back,” Hartman stresses. “It has been banned by India for export since sometime around 2005, I believe, so that’s almost 20 years now, and I see no chance of this ever-changing. What’s still available out there now is it. Game over!”

“Black-lip, gold, and white mother-of-pearl all are still available,” he adds, “just not in larger size pieces as they were 20-50 years ago. They are overharvested and not as healthy as before. Demand for shell is down overall. It is not very tactical, and we seem to be in a tactical and bushcraft market for the last two decades. Shell tended to be more of a gentleman’s pocketknife material, so it’s not exactly the big trend right now.”

“Many of the companies that used a lot of shell on knives are gone or simply don’t have the people who know how to work with it anymore,” Hartman adds. “Shell is still one of the most beautiful materials ever, so much so that it seems to be the hardest to reproduce in any type of synthetic alternative that even comes close to its natural beauty. We can come close, but there is still nothing like the real thing.”

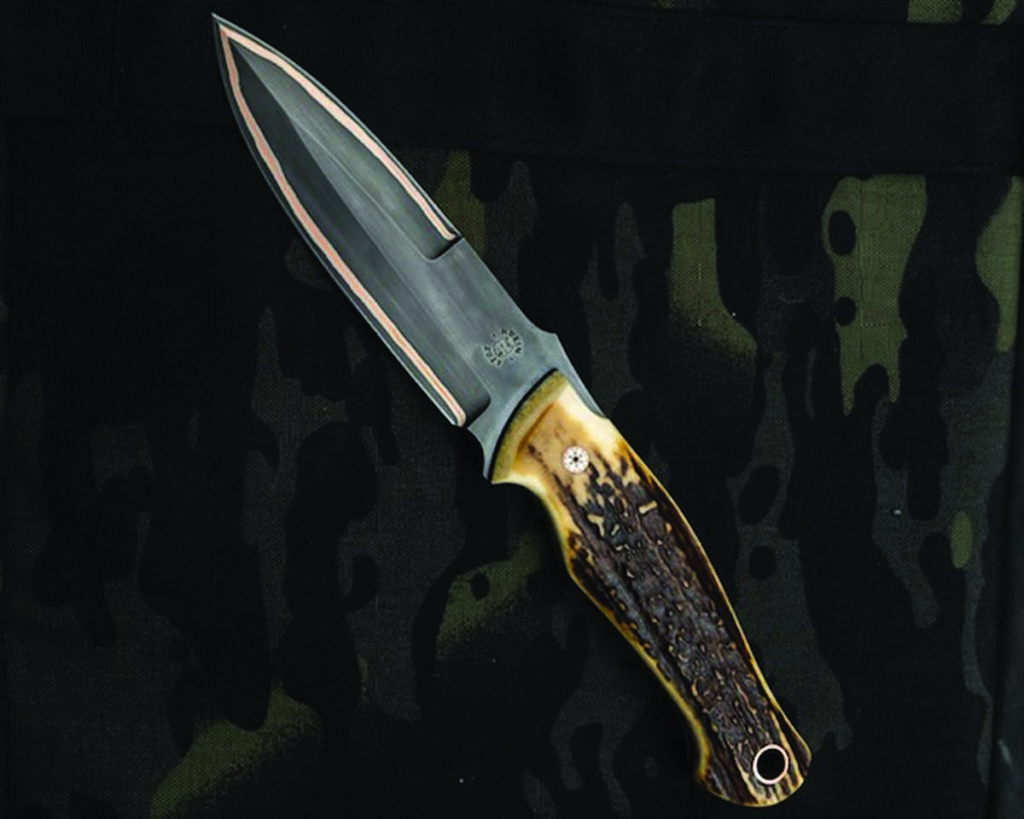

Krein sees a swing toward synthetics and higher-end natural materials as well. “Right now, there is a huge push to find and use vintage Micartas,” he relates. “I’ve also seen G-10 usage go up a ton over the years. G-10 holds up to use extremely well, is relatively inexpensive, and machines and grinds easily. I’ve also noticed quite a few new businesses that specialize in exotic stabilized woods. Stag has always been a desired and quality knifemaking material, and with exceptional stag being much harder to find, it is even more desirable, particularly when done [harvested and finished] properly.”

Watching the high-end polymer Ultem begin to trend as a new synthetic handle material has been interesting for Krein, and his affinity for giraffe bone has not waned. It’s something he calls the “latest real pickup in natural materials.”

“I often see new makers using very exotic materials,” Krein concludes. “These materials are costly and often not used anywhere close to their potential. I recommend that new makers learn to use simpler materials like Micarta to their full potential. This leaves funds available for other materials and equipment while allowing a new maker to develop their skills. Just because a knife has expensive materials doesn’t make it better or more interesting to me. It’s developing the skills to make simple materials look elegant that I appreciate.”

Those Hybrid Moments

Hybrid handle material is on the rise, and Cammenga is pleased with the growing popularity of marbled synthetics. “Right now, there is strong demand,” he notes. “This is true in both cloth/resin laminates and carbon-fiber/resin laminates. For those who want natural wood, bone or antler, acrylic ‘stabilized’ scales have been popular for quite some time. They provide the user with a natural material, which has been made tougher by introducing acrylic resin into the fibers. Currently the marbled look is in with almost all materials, but we have made several knife models using G-10 and rubber combinations, as well as others from polyester cloth and resins.”

Masecraft is keeping a close eye on the development of new materials, but the course is charted by ingenuity rather than discovery. “As far as new natural materials, that’s going to be extremely rare,” Hartman observes. “The earth is not really producing anything new, so unless we have not discovered it yet, the odds are low. More likely, some natural materials will disappear and become endangered, banned, or extinct. Human history tells us the availability of natural material will decrease while prices increase. You will see more hybrids of natural and synthetic combinations, and all kinds of new synthetics will continue to be introduced.”

Supply often dictates how well demand is satisfied, and the inherent scarcity of some handle materials has been exacerbated by supply chain concerns in areas. Even as the COVID-19 pandemic has eased, the resilience of the supply chain remains an open question. Some suppliers and makers have faced shortages of stock items, while others have adapted, moved on to other, more readily available options, or simply been patient.

“I have been sourcing materials for over 44 years, and most of our suppliers know us and what we want,” Wirtel relates. “Obviously, we’ve had supply chain issues, but we have been able to work around them. We make our product to order, so we range in delivery time from a few weeks to a few months.”

Krein is positive regarding availability, saying, “There have been slight wait times for some synthetics, particularly Micarta, during the pandemic, but it seems like everything is back on track here. There has and will continue to be more demand for quality stag than availability. I’ve seen a bit less of quality exotic stabilized woods like exhibition-grade ironwood and Koa.”

While the supply chain phenomenon has been universal, Hartman is pragmatic. Going with the flow makes the Masecraft operation run as smoothly as possible. “There are supply chain issues with everything globally,” he observes. “I can’t think of anything on the planet that hasn’t been affected in some way, shape or form and that doesn’t have a price increase or isn’t in short supply, and it’s all things, countries, and markets.”

“If you don’t have the chip, you can’t produce the car,” Hartman says. “If you don’t have OD Green dye, you can’t make OD Green G-10. If one key part is missing due to supply chain issues, the product simply cannot be made, and that is affecting all things.”

Staying domestic has been a problem solver for White River Knife & Tool, according to Cammenga. “Because White River purchases synthetic material made within the U.S., our supply chain has not been a problem. The one material we do import, cork, has increased in price, but our supply has been uninterrupted.”

Considering the handle-blade combination that makes the knife come together for the spectrum of customers and users, today’s material options appear more diverse than ever. Although some shortages in natural materials may never be plentiful again, fusions of natural and synthetic options open the door to creativity. And the imagination is always fertile ground for innovation.

More On Knife Handles:

- Best method to stabilize wood handles

- Hall-Of-Frame Handles

- G10 Knife Handles: Are They The Best?

- The Best Knife Handle-to-Blade Ratio

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.