- Easy to maintain

- Simple construction

- Versatile in a number of environments

While the definition of the “perfect” or “4.0” military knife is subjective, those who have been there know well how their knives perform and what it takes to build confidence that the indispensable tool can deliver.

So, with a clean slate, how would veterans of the military and the knife industry construct the finest knife for their own use?

1) Easy

“Durability and maintenance are primary, as they are with any tool or gun,” assessed Rob Cude, who spent 24 years in the U.S. Navy and retired in 2006 as an Explosive Ordnance Disposal Chief after completing tours in Africa, Yemen, Afghanistan and Iraq, with combat duty as a member of the CIF (Commanders in Extremis Force), a group of exceptionally trained Special Operations personnel.

“The knife must be easy to maintain and built of quality materials that stay sharp, are easy to sharpen, and strong,” Cude continued. “Any of SV [CPM S30V, etc.] series steels are really good, and Stellite® for some uses such as diving. High carbon can also be used as blade steel, but it’s all about finish and coating. My handle choice is paper or canvas Micarta with a thread-exposing finish, but the aggressive G-10 textures on fixed blades like those by Strider Knives are really good as well. The material needs to be durable and chemical resistant with a slip-resistant finish when wet.”

While on active duty, Cude carried a Spyderco Police, Benchmade and Emerson folders, and Gerber fixed blades.

“In 1996, I contacted a few custom makers to help us with a fixed blade that met a variety of needs,” he remembered. “Later, I carried Kit Carson, Jones Brothers, Strider and R.J. Martin, all excellent knives that withstood the test of time and extreme conditions.”

Both folders and fixed blades have their places in military use, Rob says. He carried folders in Kydex® sheaths with assisted-opening mechanisms like the Kershaw SpeedSafe™ designed by BLADE Magazine Cutlery Hall-Of-Fame© member Ken Onion mounted to a holster, along with small, light sheath knives in blades under 5 inches with recurves to increase the cutting edge, attached by a fabric fastener behind his chest-mounted magazine pouches.

His friendship with Cutlery-Hall-Of-Famer Kit Carson and contributions to a military knife design resulted in variants of the U2, which Buck Knives picked up as the Intrepid.

“Kit was not only a friend but a mentor in military career,” Rob noted.

2) Simple

Retired 5th Special Forces Master Sergeant and BLADE field editor Kim Breed makes knives and has done design work for Spartan Blades. He applies the KISS principle, always keeping it simple.

“The more moving parts, the higher the chance of failure,” he reasoned. “I make it a point to serve the military by providing the best knife with the soldier’s interest in mind. They provide me with important feedback on how my knives have performed, which allows me to tailor their needs into my designs.”

While serving with the Special Forces, Breed preferred lightweight knives that could perform a wide variety of tasks since most of his active duty time was spent living out of his rucksack.

“A Ferde-Lance designed by David E. Steele was always with me on every deployment. I also carried a Swiss Army knife Champion, as the tweezers and scissors were the best for removing thorns.”

For Kim, experience still points to the multifunctional blade style with a comfortable handle, and high carbon steel and Micarta are the most requested materials from active service personnel. Comfort, edge-holding ability and ease of sharpening are the top priorities.

“The fixed blade will always have a place with the soldier,” he asserted, “and some folders will be used for smaller tasks. Kydex seems to be the sheath of choice, as it is approved for airborne operations and securely holds the knife in a variety of positions. Blade shapes run the whole spectrum, but most are a version of a drop point or slightly upswept blade. A few soldiers like guards, but as long as the knife has a finger notch to keep the hand from slipping, it’s good. A bead-blasted finish is a favorite. A non-reflective blade is a must.”

3) Environmental Versatility

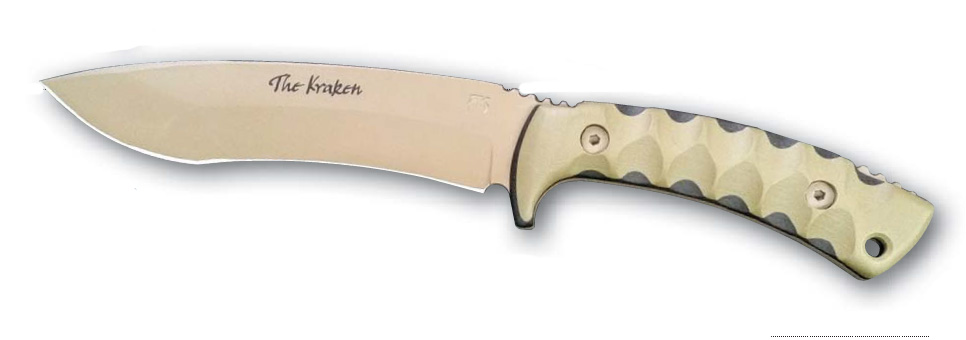

knife image)

William “Bill” Harsey Jr. has been around military-style knives for decades and worked in design with legendary Cutlery Hall-Of-Famer Col. Rex Applegate, as well as Chris Reeve Knives and Spartan Blades.

He says canvas Micarta handles are tough to beat for control in harsh conditions, including wet and cold and even in darkness. They have been approved for cleanup after exposure to chemical or biological weapons, too.

“I also believe that a knife must be able to retain its sharpness in hot and humid conditions such as marine, riverine and jungle environments,” he commented. “This takes some amount of stain resistance, as an edge can ‘go away’ in the sheath without ever being used.”

The steel of choice for Harsey is CPM S35VN, which he says mimics the traits of a true tool steel but with stainless characteristics. While he adds that good makers can utilize a range of blade steels and produce outstanding knives, non-stainless steels require more maintenance.

“One thing I’ve learned about discussing knives with members of the military is that the topic elicits strong responses, kind of like which handgun is the best,” said Harsey, who has made knives individually and in collaboration with U.S. Army Special Forces, U.S. Navy Special Warfare personnel and Canadian Special Forces.

“Many of the warfighters I know carry several knives in the field and when not in the field. Folders, fixed blades and tools all count.”

Harsey sees the basics as the most important aspects of the ideal military knife.

“I think the requirements for a good military use knife, which can be mission and region specific, are that the blade has a point, cuts and can be carried in a good sheath that works with the rest of the kit carried by the warfighter,” he concluded.

Forget the Movies

During stints with the U.S. Marine Corps and Army, Jack Stottlemire, who makes custom knives for military personnel at Fort Bragg, North Carolina, near his home, has seen many a global hotspot.

A veteran of the 7th Infantry Division (Light) during the invasion of Panama, the 82nd Airborne Division during the Gulf War of 1991, the 173rd Airborne Brigade during the Balkans air war, and a special mission unit in Special Operations during the global war on terrorism in Iraq and Afghanistan, he retired with the rank of sergeant major. Jack also has carried numerous knives.

He put away his Gerber Mk II after carrying it briefly and went with a KA-BAR that performed well in multiple functions. He also has used a Buck 110 folder, M7 bayonet, Leatherman multi-tool, Air Force survival knife, Benchmade Stryker auto, and a Horrigan Fighter made by his squadron mate, Bob Horrigan, who was killed in action June 17, 2005.

“Unlike what you see in the movies,” Stottlemire explained, “soldiers and Marines do not carry large crew-served knives like in Rambo or The Expendables. A knife is a cutting tool for everyday tasks. For silent killing when warranted, a spike hawk is used more often than not in lieu of a knife in Special Operations on today’s battlefield.”

Stottlemire’s custom knives are made under the Rustick Knives brand, and word of mouth drives his sales. He has a large following among Navy SpecWar Teams and Air Force Combat Control Teams.

“Carbon steel knives that are treated to 57-59 Rockwell are easier to sharpen in the field than most stainless steels,” he remarked. “Carbon is more affordable for the average ‘Joe’ also. I was surprised when a SEAL platoon ordered knives from me and did not want stainless. They preferred carbon with a Cerakote™ finish. Now, stainless does have its place, especially in a humid environment like Central America where you can actually watch an unprotected edge rust. But with proper maintenance and protective finishes, carbon can excel in these areas.”

Jack’s handle material of choice is G-10 and he uses that on all the custom knives he produces.

“It’s very tough and durable stuff that stands up to any abuse you throw at it,” he said. “Micarta would my second choice.”

From a military man’s perspective, Stottlemire says a knife needs to do one thing well—cut. Added options such as wrenches, screwdrivers or bottle openers are unnecessary in the field. A good point with a blade of 4-to-5 inches is usually more than enough to do the job well.

It Comes Down to Individual Preference

Overall, both fixed blades and folders useful in the field. Handles of durable synthetic such as Micarta are the top choice, while blade steel is a toss-up between carbon and stainless.

A blade length of up to 5 inches is ideal. Personal preference, though, remains a major factor, and the individual has the opportunity to decide what knife or knives to employ.

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.