Here’s why knifemakers use titanium:

- Lightweight and tough

- Softer than steel

- It’s a reactive metal

In the knife world, titanium has been at the forefront of space-age metals for well over two decades, due in great part to the boom in the tactical knife genre borne out of the first Gulf War in the early 1990s. Titanium was originally used in the U.S. space program for its weight savings and toughness, and from there bled into military programs for the very same characteristics.

Titanium is also nonmagnetic, proving useful in certain applications. While tough, titanium is softer than steel, and although some knifemakers have used it as blade material, it never quite caught fire like the new exotic stainless steels that dominate the upper end of the market today.

Aluminum is also nonmagnetic and anodizes quite well, but it gets little respect in the knife industry because as an extremely soft metal it’s considered an inexpensive alternative to titanium.

Titanium is a reactive metal—its characteristics can be changed by outside influences. Heat-treating knife handles or dipping them into an electrolyte solution that has been both positively and negatively charged color enhances the metallic surface. The amount of heat or electric charging can be varied by the amount of direct heat or voltage applied, and this determines the color hue that the metal takes.

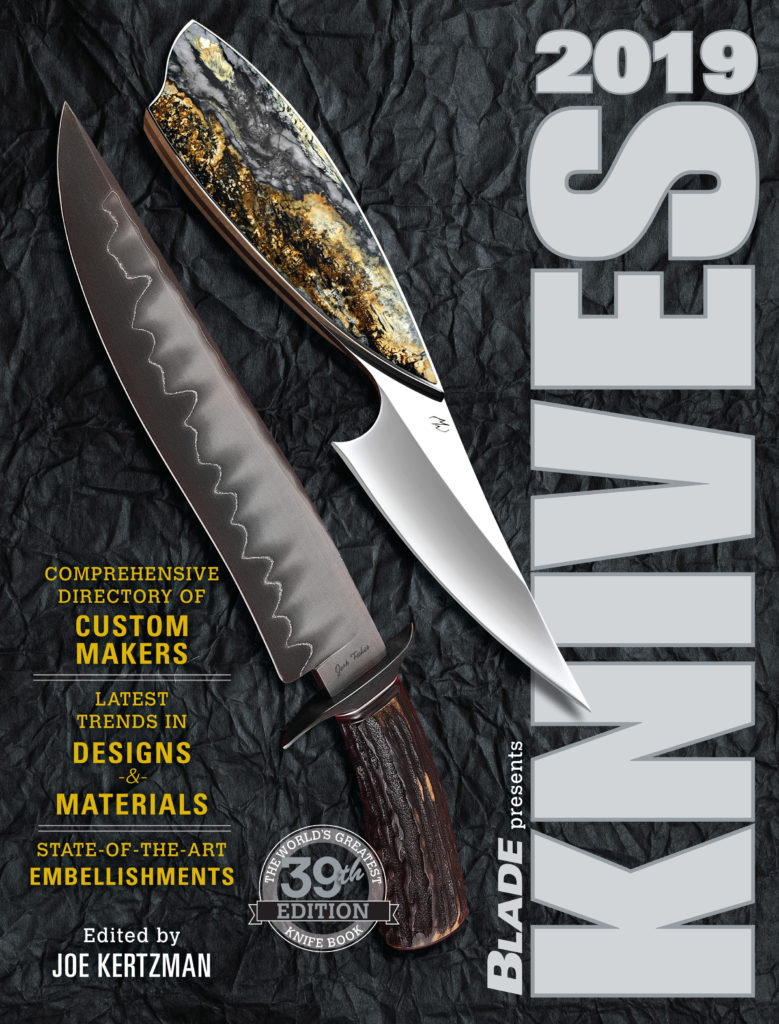

Learn More About Knifemaking in the World’s Greatest Knife Book

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.