Affordable game shears that offer cut, power, features, size and more…

When you think of processing game, a skinner is typically the first knife that comes to mind—and rightfully so. At the same time, game shears provide a viable role in the processing equation, particularly with small game like squirrels, rabbits, fowl and fish. A good pair of shears made for small game processing can cut through bone, slice hide, remove unwanted viscera and, in the case of fish, remove heads and fins. Many shears have extras thrown in, technically making them multi-tools, though that’s a bit of a stretch.

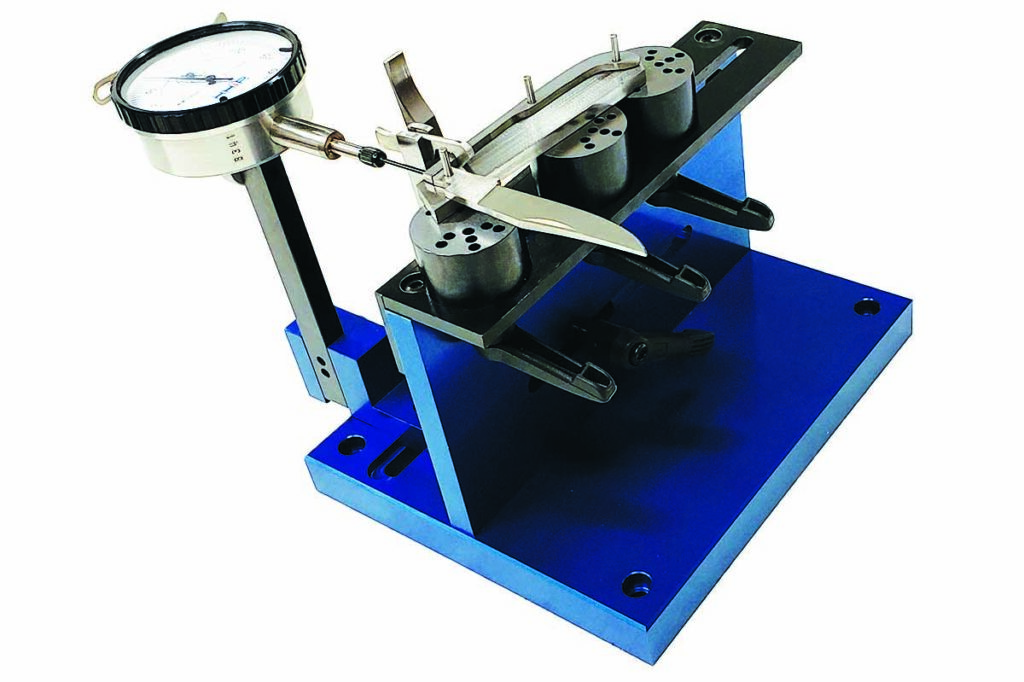

My team tested four current game shears to see how they perform and what they offer in the way of goodies. Just so we don’t get repetitive, it should be noted that all our candidates have take-apart pivots that allow the main blade/handle sections to separate for easy cleaning.

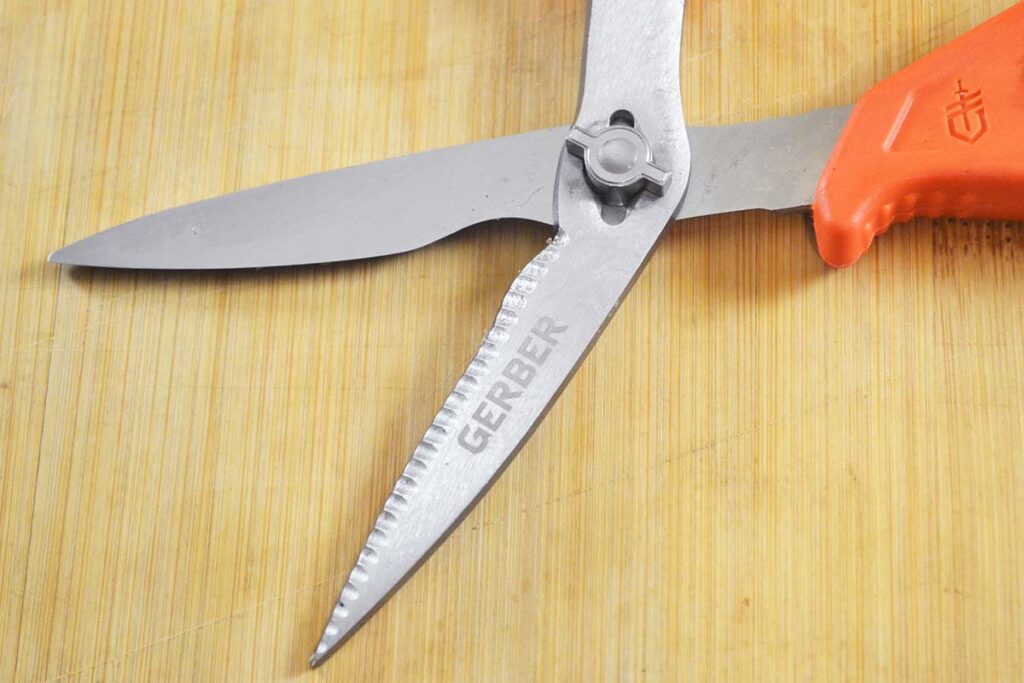

Gerber Vital Take-A-Part Shears

The simplest and smallest of the test group is the Gerber Vital Take-A-Part Shears. The spear-shaped blades are 2.5 inches of 420J2 stainless steel. Overall length: 8 inches. The handles have a hard thermoplastic frame sporting rubbery Kraton™ overlays with an ovate hole for the fingers and a round one for the thumb. One blade is plain with a bone notch and the opposing one is fully serrated. A two-color nylon sheath matches the handle. Weight: 5 ounces. Country of origin: China. MSRP: $20.

Kershaw Taskmaster Shears

The Kershaw Taskmaster Shears is a straight-blade design with a nice assortment of built-in goodies. The 3.5-inch blades are stainless steel. The spear-point patterns include one plain edge and the other partially serrated with a bone notch. The grips are finger-loop style and overlaid in black Kraton. Additional features include a lid lifter, bottle opener, screwdriver, nutcracker and jar opener. Weight: 5.1 ounces. Overall length: 8.875 inches. Country of origin: China. MSRP: $26.73.

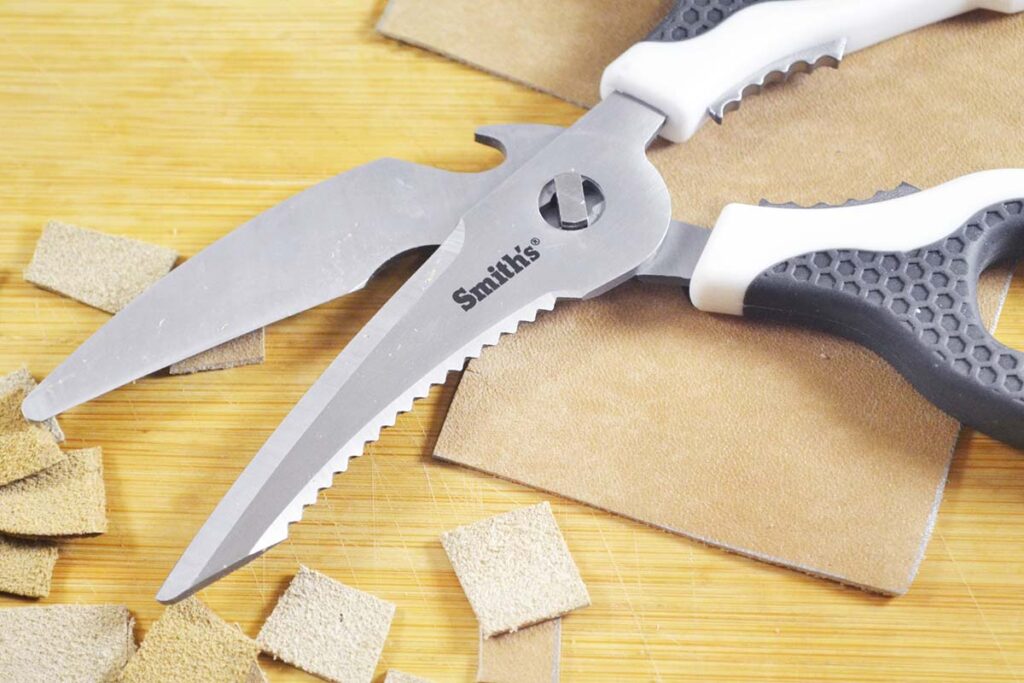

Smith’s Edgesport Bait & Game Shears

The Smith’s Edgesport Bait & Game Shears is the most elaborate of the group we tested. The curved blades are 3 inches each of stainless steel. One’s a plain edge and the other is serrated, but what really sets them apart is the curved fish scaler on the underside of the plain blade. The handles have a thumb hole and opposing finger hole with black Kraton over a white thermoplastic main frame. Additional functions include a nutcracker, screwdriver, bone notch and cap lifter. There is no pouch. Weight: 5.25 ounces. Overall length: 8.5 inches. Country of origin: China. MSRP: $28.99.

Outdoor Edge Game Shears

The Outdoor Edge Game Shears is the juggernaut of the bunch. What it lacks in features it makes up for in size. Respective blade and overall lengths: 3.75 and 10.5 inches. Another distinguishing feature is it’s spring-loaded with a swing lock at the base. This negates the need for manually opening the blades after making a cut—the spring does it for you. The wharncliffe blades are a plain edge and the other partially serrated with a healthy bone notch. Handles are ribbed Kraton. Weight: 10.5 ounces. A pouch is included. Country of origin: China. MSRP: $49.95.

Testing Shears

I focused on the main job of shearing first. I started with some basic straight cutting exercises of suede leather to simulate animal hide. All the candidates performed the scissor cuts well with the exception of the Outdoor Edge shears, which are just too big for such small detail tasks. As you’ll see later, the Outdoor Edge more than makes up for this deficiency in other areas. The Gerber cut best because it is the only test shears that has a humped serrated blade opposite the bone notch. It just keeps on cutting like a standard scissors whereas the others bog down when they hit the notch.

Next I tested each model’s bone notch, a great feature I’ve only seen on game shears that is worth its weight in gold. I used the shears on chicken bones as they were the easiest to get in the 15-to-25°F cold snaps we were experiencing at test time. The humerus and femur are the largest “rounded” bones in a chicken skeleton, offering the best way to gauge cutting power. This is where the Outdoor Edge shears excelled. It munched its way through the larger bones with ease while the smaller shears had a hard time opening up wide enough to be able to grip them. All the review shears performed well on smaller bones, as well as cutting through the cartilage and viscera around the joints.

Hightlighting Features

The Gerber and Outdoor Edge Shears are sparing in the multi-implement category. The Kershaw and Smith’s, on the other hand, offer a wide range of added features. Most impressive on the Kershaw is the way the lid lifter, bottle opener, screwdriver, nutcracker and jar opener are incorporated into the design. You don’t really notice the various little helpers, but you’ll be darn glad they’re there when you need them. What’s more, the fish scaler on the Smith’s shears could be a real game changer for the outdoorsman who enjoys fishing as much as hunting, or is solely into angling.

Final Cut

The good news for game shears users is choices abound in this small sliver of the overall cutlery industry. For starters, pricewise none of the test shears are going to break the bank. The small Gerber and large Outdoor Edge will please those who could care less about the extras. For them, a sharp shears with a bone notch is all they need. For those who like bonus functions on their shears, the well-organized Kershaw will perform a myriad of chores. Finally, the gamesman who prefers a loaded shears with a little something extra will appreciate the fish scaler on the Smith’s entry. Between the four choices there’s bound to be a game shears ready to work for you.

Check Out More Outdoor Knives:

- BEST TOMAHAWKS: OUR TOP HAWKS FOR BACKWOODS TO BATTLEFIELDS

- BEST BUSHCRAFT KNIFE: WHEN STEEL MEETS THE WOODS

- BEST EDC FIXED BLADE KNIFE: A CUT ABOVE THE REST

- BEST CAMP KNIVES: OUTDOORS DO-ALLS