Hot bearded axes go beyond just chopping.

All axe heads have an edge, of course, but did you know some can give you an edge over others? The bearded axe chops just like any axe, but its beard can serve field duty beyond the norm.

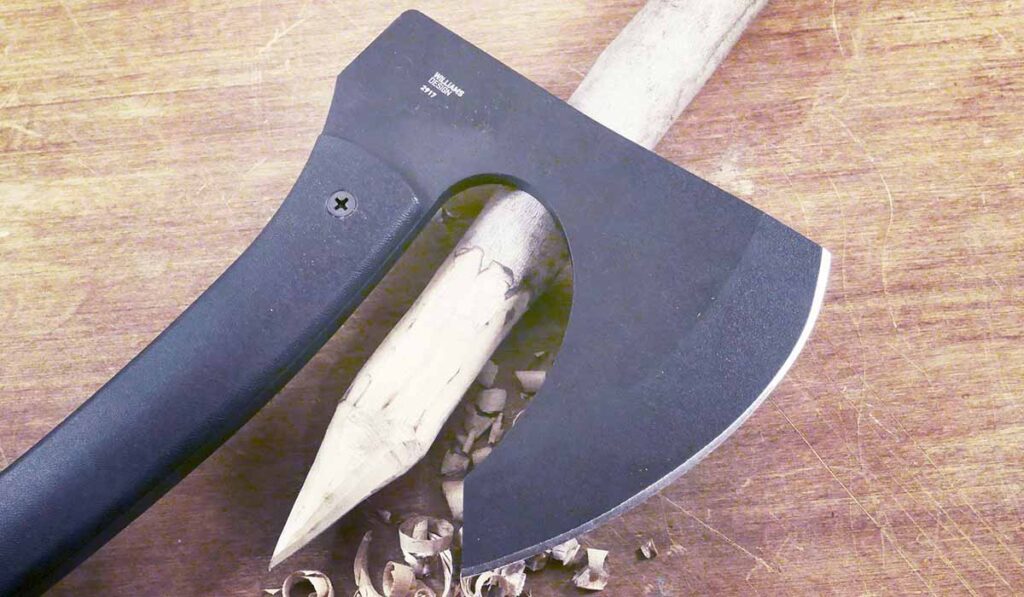

The bearded axe was first used by the Scandinavian Norse people (Norsemen) in the Middle Ages and was called a skeggox—skegg for beard and ox for axe. Its distinctive shape allows you to grasp the handle at the base of the head and use the edge for woodworking chores.

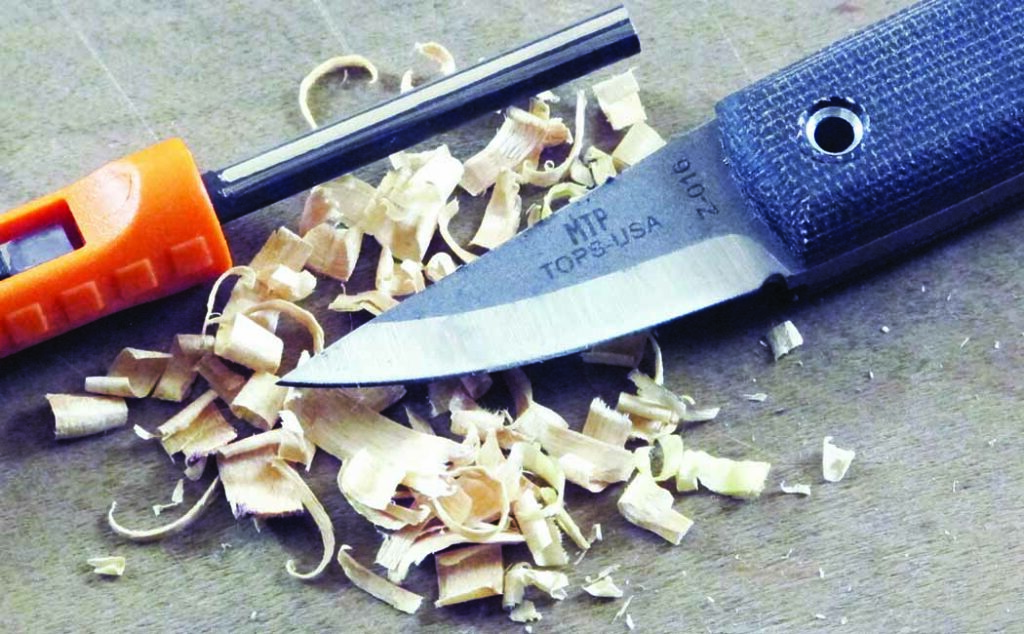

It’s sometimes called a carving axe for its propensity for de-barking, shaving and notching wood, and other chores like slicing cord and rope—even serving as an ulu to prepare food. Not all bearded axes are made specifically for carving wood, however, as you’re about to find out.

CRKT James Williams Skeggox

Columbia River Knife & Tool and martial artist/Japanese sword guru James Williams dipped back in time and chose the original Norse namesake for his design. The CRKT Skeggox is one of the larger two test axes.

The drop in the beard from the top of the inner curve to the bottom edge is 3.25 inches. The 11-inch handle has a lanyard loop at the base. The sheath features a black nylon keeper strap with a thermoplastic buckle to prevent slippage from the sheath. CRKT includes additional hardware for belt or MOLLE carry.

The SK5 carbon steel of the axe head has been compared to U.S.-produced 1084 and 1095 carbon steels, which typically fare well-working wood in the wild. I tested it for carving and immediately liked the deep drop and the “50 miles of elbow room” between the handle and the rear of the beard. I de-barked and pointed a fat hardwood tent peg, and the more I used the bearded blade the better my control got for taking off long shavings. This was in part due to the low profile of the quarter-inch steel and the nice bite of the high carbon alloy.

The Skeggox is also a good all-around chopper for firewood and clearing small trees. The sheath is economical and the option of belt or MOLLE carry is welcome. Better yet, it is the most affordable of the review axes and money well spent.

James Williams Skeggox Specs

Head Width: 4.874”

Blade Edge: 5”

Blade Material: SK-5 carbon steel (Japan)

Blade Thickness: .25”

Blade Finish: Black powder coat

Handle Material: Black FRN polymer

Weight: 26 ozs.

Overall Length: 13”

Sheath: Black thermoplastic

Country of Origin: Taiwan

MSRP: $113

Doublestar/Outlier Kodiak Camp Axe

The Outlier (formerly Doublestar) Kodiak Camp Axe is the second of the larger test axes and comes with a twist. The axe head has a removable steel splitter attachment installed, specifically made for cleaving wood. It is also notable in that the blade edge has two grinds.

The beard drop is 2.5 inches. The handle scales are sumptuous at a half-inch thick each. The sheath covers the axe head and splitter until it reaches the widened rear of the splitter used for hammering. The front has a nylon belly strap with a thermoplastic buckle to secure the axe head.

The splitter increases weight, blocks access to the beard for slicing and shaving, and is too unwieldy for my tastes for finesse work. I removed it, reducing axe weight by 8 ounces and making the Kodiak much easier to manipulate. I thought the two angles of edge might make a difference in cutting surface—and I’m sure they would—but the longer, lower edge turned out to be all I needed for de-barking and shaving long slivers. The 52100 carbon steel cut like a house afire, slicing wood and ¾-inch rappelling rope with ease.

It was a different axe altogether without the splitter and more in line with the other text axes. The only recommendation I’d have is that Outlier offer the same axe with a full, single-edged head to increase the coverage of the edge. Other than that, it’s a beast.

Kodiak Camp Axe Specs

Head Width: 5.25”

Blade Edge: Varied

Blade Material: 52100 carbon steel

Blade Thickness: .25”

Blade Finish: Parkerized black

Handle Material: Green G-10 composite w/orange liners

Special Features: Splitter attachment

Weight: 40 ozs. (including splitter)

Overall Length: 13.125”

Sheath: Black thermoplastic

Country of Origin: U.S.A.

MSRP: $319

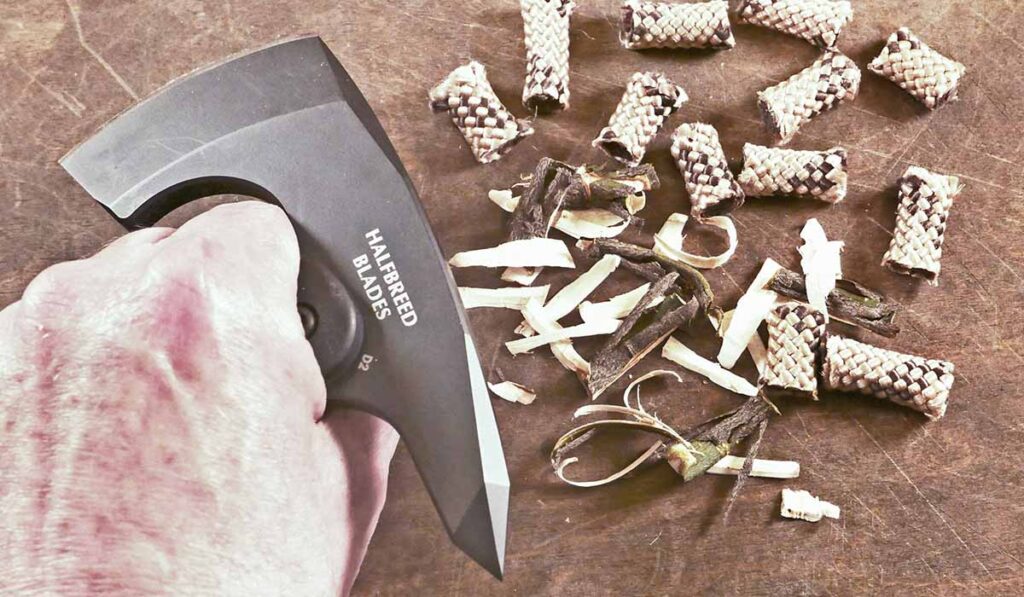

Halfbreed Compact Rescue Axe

The Halfbreed Compact Rescue Axe is the smallest of our bearded array yet is also the most overbuilt. It makes up for its smaller size with the thick axe head steel. There’s a nice palm swell at the lower grip area and a big finger groove at the top of the handle.

It has a beard drop of 1.5 inches. Out back is a 2-inch spike. The rear spine has gimping to enhance grip. The sheath offers full coverage and a keeper loop rolls under the bit to further secure the axe head. It has a mounted MOLLE-compatible plate, or you can swap it out with an optional DOTS Tek-Lok style attachment for belt carry.

While testing the Halfbreed I had to remind myself it is indeed a compact rescue axe. While all the other review subjects are geared for outdoor use, this small overbuilt wonder is more for city work. That said, the large finger groove at the top of the handle is custom-made for carving and slicing just as bearded axes were intended. I tested the little axe and it shaved bark, took off shavings, and sliced rappelling rope just fine, but its thick steel and superior weight-for-size ratio really shine when hacking and bashing. I have no doubt it would earn its stars as a close-quarters hawk.

I gave the spike a run on a pane of 3/16-inch door glass and it obliged, shattering it with gusto. The ample grip, with its added gimping, makes for excellent purchase, and the sheath—overbuilt like the axe—is the most comprehensive of the lot. In a nutshell, the Halfbreed is a handy axe—and a bulldog at that!

Compact Rescue Axe Specs

Head Width: 4.5”

Blade Edge: 2.55”

Blade Material: Bohler K110 (D2) tool steel

Blade Thickness: .31”

Blade Finish: Black Teflon coating

Handle Material: Black G-10 composite

Special Features: Faceted spike, gimping

Weight: 25.07 ozs.

Overall Length: 9.52”

Sheath: Black Kydex, MOLLE compatible

Country of Origin: Australia

MSRP: $310

Maserin Knives Mantis

Maserin Knives may be giving us a glimpse into the future with its new, strikingly stylish Mantis. It is a small axe and you’ll notice the steep tool steel blade is quite lengthy for its size. In fact, the blade exceeds the width of the axe head—a bit unusual in a working axe.

“But wait, there’s more!” as the TV guy says. The Mantis has four (two sets) of scales: one at the top for carving comfort and the other on the lower portion of the handle for grip. At the base of the straight top scale the direction of the handle switches to an outward curve, and the exposed part on the handle has three lightening holes—plus there’s a lanyard hole and a spike on the base. The sheath fits the axe head only and butts against the top scale, and there’s a belt loop stitched to the back. It’s minimalism at its finest.

The Mantis has the longest beard drop of all the test axes at 3.75 inches and is the only one that offers full hand protection. The blade curve stands apart in that it is virtually symmetrical from end to end. It’s shape and full knuckle protection begged me to try it as an ulu for slicing, so I laid down some 3/8-inch rappelling rope and went at it. The Mantis sliced just like an ulu, taking off clean sections of rope. It performed even better when I reversed the grip with the handle facing away from me so it didn’t hit me in the belly. Voila! Instant ulu.

The Mantis shaved bark and carved off curls quite well and the full finger protection was welcome. It’s the lightest of the axes reviewed, which could put it at a disadvantage to the others when weight is a factor. You won’t be batonning this axe either because the top scales would block it from going past the front portion of the head. That said, there’s plenty to like about the Mantis’s utility value and its forward-thinking styling!

Mantis Specs

Head Width: 3.75”

Blade Edge: 4.527”

Blade Material: D2 tool steel

Blade Finish: Stonewashed

Blade Thickness: .326”

Handle Material: Black G-10 composite

Special Feature: Futuristic design

Weight: 20.23 ozs.

Overall Length: 11.02”

Sheath: Black Kydex

Country of Origin: Italy

MSRP: $216