Maybe it’s a bit of a contradiction, but both elegance and simplicity are elements of African blackwood, a handle material with a rapidly rising profile in the custom knife industry.

The color of the material combined with properties that make it a pleasure to work with has resulted in an explosion of interest. Ranging in luster from a reddish to a deep black hue, the wood is the product of a flowering tree also known as granadilla or mpingo. A relatively small tree, it grows primarily in the forests of Senegal east to the horn of Africa and in some parts of South Africa. Long used in musical instruments and high-end furniture, African blackwood is protected in order to prevent overharvesting.

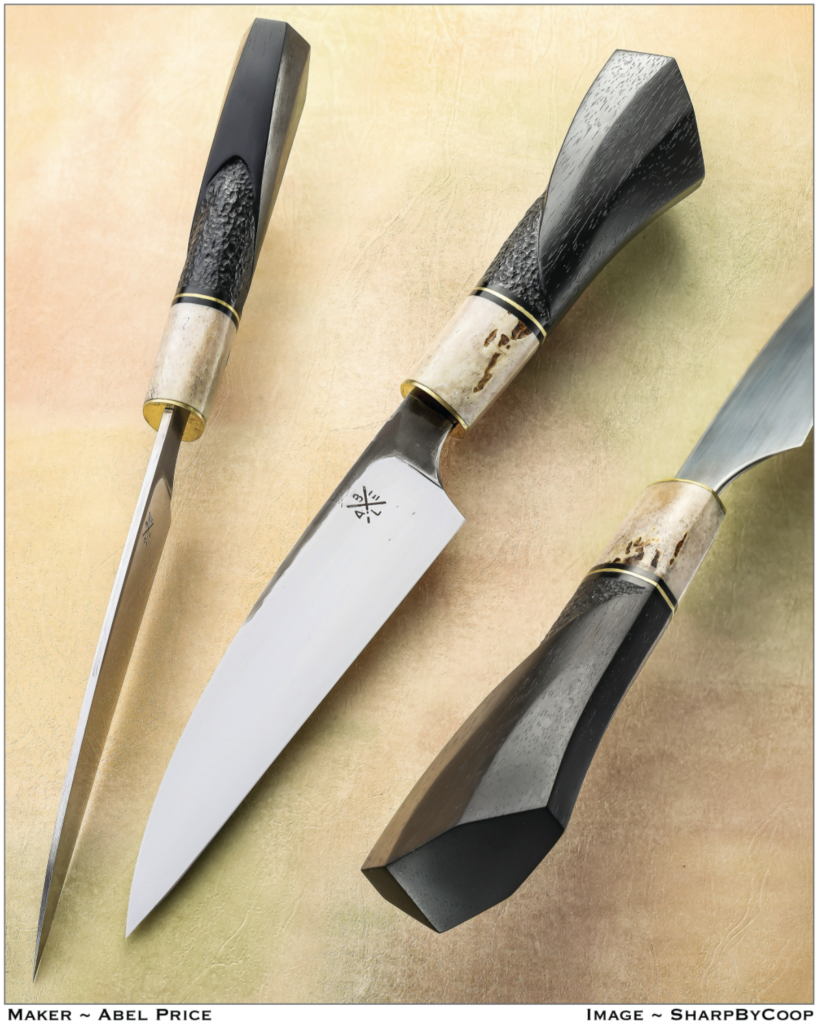

When the material finds its way to a knife handle, something dazzling happens, and the makers who use it sing its praises. “I’ve always loved black-handled knives, especially with brass,” related Abel Price of Fayetteville, Arkansas, a part-time maker who is completely self-taught. “The black and gold combo just pops and gives it a beautifully elegant Art Deco feel.”

In the mountains of western North Carolina, ABS master smith Andrew Meers finds African blackwood a pleasure to work with. “It’s a dense and stable wood with a consistent grain structure that is excellent for handle material. It is workable and carves well,” he noted. “It has a rich, dark color and finishes out beautifully when sanded, and I haven’t noticed any cracking, shrinking or expanding, especially compared to the cracking I’ve noticed at times in similar looking wood such as ebony. I think these qualities contribute to its growing popularity among makers.”

Andrew uses rasps and files for shaping, a flex shaft for carving, and prefers to sand and buff to finish his handles of the material. Last of all, he applies a coat of Danish oil. So, the finished product is just what the maker wants, and getting there is most often a pleasurable journey rather than an arduous trek. African blackwood exhibits excellent stability and takes a shine quite well. Custom makers agree that the material is ideal for carving, though whether it carves easily or not is open to the interpretation of the individual maker.

“I think the main reason for its carving ability is that it is hard,” commented Pekka Tuominen, a 17-year maker from Keitele, Finland. “Wood has to be hard if you wish to carve it with sharp and tight curves, and also polish those curves. Let’s say it’s not easy to carve, but when wood is hard you can get a good finish. Of course, it’s popular, too,” he observed. “Everybody knows that if some famous knifemaker uses a material, then the rest of the makers at least want to test it.”

MORE ATTRIBUTES

Waynesville, North Carolina-based ABS journeyman smith Ken Hall appreciates additional attributes of African blackwood. “I like using it because it’s a very dense wood, doesn’t require stabilizing, is hard and does not crack easily,” he stated. “It has a tight grain structure, so you don’t have to fill voids, and it can be carved or shaped without difficulty and provides a dark contrast to a steel blade.”

Securing the handle to the blade most often involves a quality epoxy and a combination of pins, depending on the type of knife under construction. “I use rivets, pins and epoxy,” Pekka said, “but I don’t use African blackwood for full tangs. With hidden tangs sometimes just epoxy will keep the tang solid inside the handle.”

When Price went to work on his Deco Petty, a kitchen knife creation with a 6.5-inch blade of AEB-L stainless steel, overall length of 12 inches, and a handle of African blackwood, deer antler and a copper spacer, he knew just what he wanted to achieve. “The goal was to hit form and function,” he commented. “The ultra-thin cutting edge flexes with lateral pressure, and a Rockwell hardness of 61 [HRC] makes for a laser sharp tool in the kitchen. The handle was sculpted to contain design elements of the Art Deco era while hitting several notes of contrast: smooth and stippled, round and flat, black and white, and straight and sweeping lines. African blackwood does everything you want it to do with a perfect finish.”

Hall fashioned his sgian dubh as an interpretation of a historical Scottish knife. “African blackwood is the ideal wood for the sgian dubh because it can be carved and shaped to the hourglass design of the traditional sgian dubh handle,” he noted, “and provide an eye-catching contrast to the stainless steel bolster and pommel.” He added that blackwood is his preferred wood for a handle with a keyhole design because it can take the force applied to pressing the wood into the keyhole.

AESTHETICS & FUNCTION

Meers made the striking Vulpecula with a 12-inch damascus blade of 1084 carbon and 15N20 nickel alloy steels. Meanwhile, something of a surprise is embedded in the African blackwood handle.

“Vulpecula is a reliquary dagger,” Andrew explained. “It is inspired by the tradition of keeping objects, often hair or remains, in an embellished vessel. I found a fox tooth and had it sealed in a glass vial by a friend. I then built this dagger to house the vial as a reliquary.

“The blade fittings and handle are adorned with 24-karat gold inlay depicting a large fox, its skull and paw prints. The hardware is torch-cut steel plated with gold that is brushed back. Vulpecula, the ‘Little Fox’ constellation, is set into the blade with blue diamonds.

“It was a combination of aesthetic and functional choices that made me choose blackwood for this piece,” he concluded. “The wood machines and carves well, so for this handle it was the ideal choice. The blackwood’s depth serves as a rich contrast to the bright gold used in small inlays to represent a starry sky and the fox prints as well.”

Tuominen built his Protector, or Suojaleijee, dagger with a 5-inch welded damascus blade of 1080 and 80CrV2 carbon and 15N20 nickel-alloy steels, a guard of Nicorros (a copper/nickel alloy), African blackwood handle, and a handmade leather sheath with stainless clip. The blade is 7 inches and overall length is 12 inches. “It’s a custom order for an American collector,” he noted. “I used African blackwood because it’s black and more stable than other black-colored woods.”

SOURCES

While African blackwood remains protected, it can be found through various sources. However, Abel has a warning.

“I stocked up at a Rockler store a few years ago,” he remarked. “I’m not looking forward to finding another supplier. I believe the demand is outpacing the supply, and as conservation efforts increase, as they should, so will the price.”

ploys African blackwood

and sterling silver for the

handle of her dagger. The

blade is a damascus of

1075 spring and 15N20

nickel-alloy steel.

Hall searches eBay for African blackwood and makes his selection based on what is available. Pricing, he says, runs $20 to $30 for a handle block or set of scales. While Pekka often sources his African blackwood from European knife shows, he also checks the internet for block-size pieces. Meers has had success with retail suppliers and finds a broad range of dimensions.

The custom knifemaker and the consumer alike have taken a new interest in African blackwood, and that fascination is not likely to fade in the near future.

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.