There are no locks to fail in the balisong—other than “letting go”

The sleek lines of the balisong, a.k.a. the butterfly knife, draw collectors and admirers like a moth to a flame. Smooth opening with a two-handle sweep in the blink of an eye adds to the allure of this somewhat mysterious knife. Meanwhile, custom makers and manufacturers have found its mechanics and optimal operation challenging to perfect.

The origin of the butterfly knife is the object of conjecture. Though modern aficionados immediately recognize the role of Filipino makers from the early 20th century in popularizing the style, it is apparent the design dates from centuries earlier. According to balisong maker Chuck Gedraitis, the knife is also referred to as a Batangas knife after the Tagalog province of Batangas in the Philippines, where it has been traditionally made. There is also evidence that its origin is European. Collector Chuck Gollnick says he owns a French butterfly knife that dates from the 1750s, and a British example in sterling silver with hallmarks that trace it to 1873. As a result of Spanish involvement in the Philippines from the 16th through the 19th centuries, Spain also has been listed as a player in the balisong’s development.

The continuing discussion of the knife’s heritage adds to the style’s romance and mystique. For both makers and collectors, the conversation is sure to continue.

BUTTERFLY HEART

The heart of the butterfly is its pivot mechanism, enabling the flipping action for which the knife is famous. Opinions vary on the best mechanical configuration, with several in use today that adequately fulfill their intended purpose.

“A balisong can best be described as a ‘folding fixed blade,’ as there is typically no mechanism,” offered Vance Collver of Benchmade Knife Co., a leading manufacturer of butterfly knives. “With the exception of the modern spring latch, there are no springs incorporated in the design. All other locking-folder designs require some sort of spring technology to function. With the balisong, the handle is essentially just split in half down the middle. Each half is attached to the blade so it can pivot. This allows the two handle halves to fold around the blade itself, acting as a sheath, in a sense.”

Collver explains that the user’s hand is essentially the lock for the split handle, and some type of latch keeps the handle halves from parting, though a latch is not necessary and the user’s grip maintains the position.

“When in use, both handles are gripped,” he added, “making the ‘lock mechanism’ as strong as the user’s grip. There are no locks to fail other than letting go. All balisongs are the same with two handle halves pivoting at the blade tang, so the mechanism is more a question of what the best examples are with this style knife.”

Collver identifies billet construction, in which both handle halves are machined completely from solid material; casting production, which is a variant of the billet process; the sandwich style, in which the handle halves are made from various components fastened together; and folded construction, in which the halves begin as a flat sheet material such as brass and are then folded into a “U” shape. For open and closed stops, single or dual tang pins are used.

Maker Darrel Ralph says he considers the balisong one of the world’s strongest folding knives. He describes the pivot as equal parts simple and intricate.

“The handles pivot on the blade independently,” he said. “This allows for offset, unique and crazy tricks or flips with the handles and blade. The secret is to be confident and always keep the ‘safe handle’—the handle that allows the back of the blade to ricochet off your hand—oriented properly as you flip.”

REVISED THINKING

Recently, Ralph has revised his thinking in regard to balisong mechanics.

“Over the last three years we stopped making butterfly knives altogether and went back to the drawing board,” he maintained. “In this time, we examined all the issues our customers gave us with the knives we had been building. We took the problems one at a time and developed new, out-of-the-box ideas to resolve them.”

Darrel says he considers bushing- or bearing-style pivots to be critical elements of the balisong, and his company uses both.

“Bearings have had a hard knock over the last 10 years in balis, mostly because of the build. We feel that the Maxx Glide pivot bearing system that we have developed is one of the best on the market today,” he opined. “This system is overbuilt and brings the bali to a whole new level. The bushing system is second in our opinion. It’s a good system that is easy to work with. It holds the handles apart and allows for a good, smooth swing on the blade. Both are great systems, and we use both according to what the customer wants in the knife.”

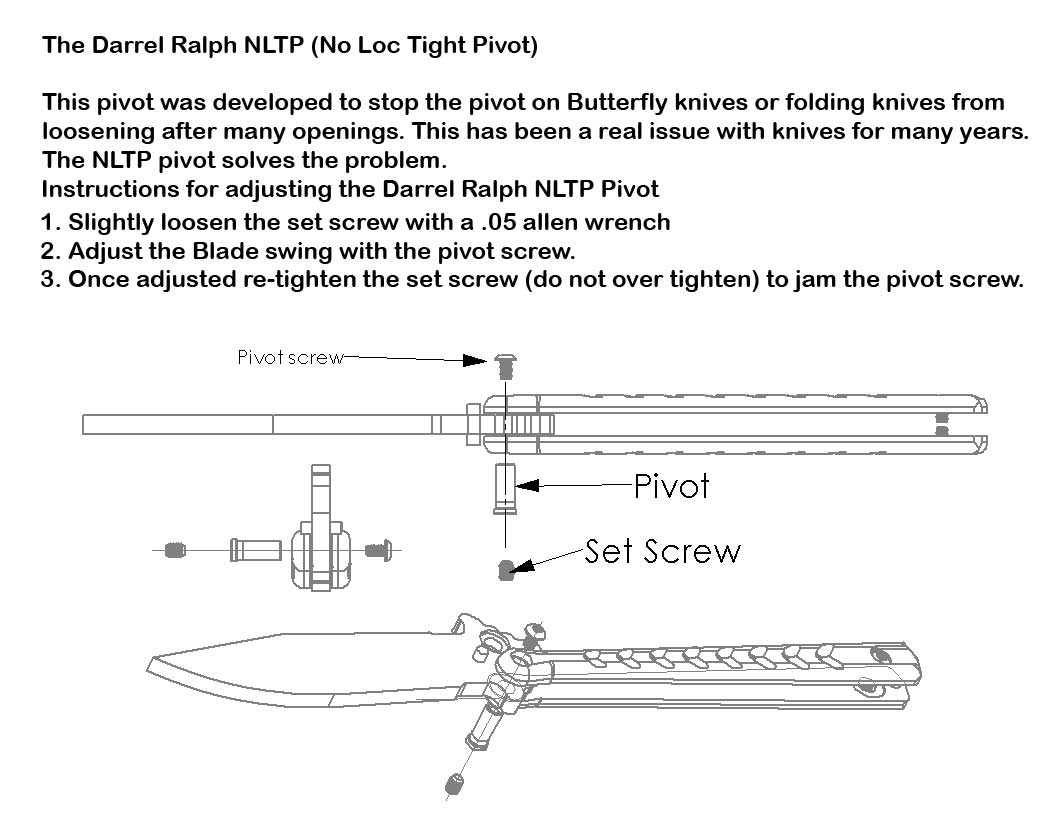

For years, Ralph says he heard concerns about both custom or production balisong pivots loosening after thousands of flips. To correct the problem, his designers developed the NLTP (No Loc Tight Pivot) system, which locks the pivot down and does not allow it to come loose, teaming up a set screw on one side and an adjustment screw on the other. Ralph’s Holey Moley model pictured above features the NLTP. A tension-adjustable latch also has been added, and the UFM (Ultimate Flipping Machine), a new generation of butterfly knife, is now in development.

BUSHING BACKER

Gedraitis identifies four main parts to a butterfly knife: the blade, two handle halves that pivot to expose or enclose the blade, and the latch. He uses pins or adjustable pivots to attach the handle halves to the blade. Most modern makers opt for adjustable pivots to allow the flipper to adjust the speed of the handle halves, he asserts, each acting independently of the other. He adds that the best examples of balisong operation are those that use a bushing system.

“A bushing is inserted into the blade, and it is one thousandth of an inch thicker than the blade,” he commented. “The pivot is inserted into the bushing. The handles are added and the pivot screws are tightened. The handles pinch the sides of the bushing, and the blade rides on the bushing. This allows the flipper to adjust the screws on the pivots very tight, and the blade still moves freely on the bushing. This also keeps the tang of the knife from being scratched or rubbed by the handles.

“A good balisong is made of quality materials and can be flipped by anyone. It has tight tolerances, washers, adjustable pivots and good balance. Bad balisongs are those made of cheap materials that are unbalanced and don’t flip properly.”

A collector of butterfly knives for more than 20 years, Gollnick lauds the simple design and strength of the lock-up. “It works well,” he noted, “and I believe it’s the strongest lock out there. The entire mechanism is visible and can be inspected so you would know if it has been compromised. We’re seeing the best products ever now, and quality is repeatable with manufacturers cranking out consistent knives.”

Continuing quality is reflected in the feel of the finished product. “It’s like any other knife, materials, craftsmanship and style,” Collver said. Added Ralph, “The collector wants fit, finish and exotic materials. The handles should be a little heavy in the rear to make the flippers happy. The handles should also be tight with good trick capability, including shape, rounded and not flat, and proper taper from front to back. Good blade weight and balance with fast speed and great pivots are other main points.”—by Mike Haskew

A New Balisong Club

If you are into balisongs and looking for likeminded individuals, Darrel Ralph said a new club called the Disciples may be for you.

“We have combined forces with Stu Hopson, expert flipper, to focus the club on developing a flipping team that is second to none,” Ralph noted, “while training and sharing with up-and-coming flippers who want to get involved and grow to a champion level. We will also be working very hard to develop new ideas for butterfly knives to make technological advancements.”

For more information contact Darrel Ralph, Dept. BL8, 4185 S. St. Rt. 605, Galena, OH 43021 740-965-9970 www.darrelralph.com.

For more on the latest knives, knife legislation, knifemaking instruction, knife trends, knifemakers, what knives to buy and where and much more, subscribe to BLADE® Magazine, the World’s No. 1 Knife Publication. Click on http://www.shopblade.com/blade-magazine-one-year-subscription-us/?r+ssfb071912 for more information.

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

NEXT STEP: Download Your Free KNIFE GUIDE Issue of BLADE Magazine

BLADE’s annual Knife Guide Issue features the newest knives and sharpeners, plus knife and axe reviews, knife sheaths, kit knives and a Knife Industry Directory.Get your FREE digital PDF instant download of the annual Knife Guide. No, really! We will email it to you right now when you subscribe to the BLADE email newsletter.

[…] knives, also known as balisongs, are one of the most popular knife styles today. They consist of a blade with two handles that […]