Looking for a tough and ready option for EDC? Here are 4 factory high-carbon steel knife options that wear and use the reliable 1095 steel well.

Knives in tried-and-true carbon blade steels such as 1095 often are left out of the conversation. Do they still have relevance in the modern world of knives? The short answer is yes—and they remain relevant for the same advantages that made them popular in the first place.

“There are a number of reasons why 1095 is popular with consumers and manufacturers,” states Joe Bradley, sales and marketing manager for KA-BAR Knives. “It’s a great steel to work with and maintain, which is the primary reason we have used 1095 Cro-Van for decades.” Says Shane Adams, marketing director for ESEE Knives, “It takes a beating and is field-serviceable. We know it, use it and trust it with our lives.” Adds Jeremiah Heffelfinger of TOPS Knives, “1095 is also easier to sharpen, especially in the field, than some stainless steels.”

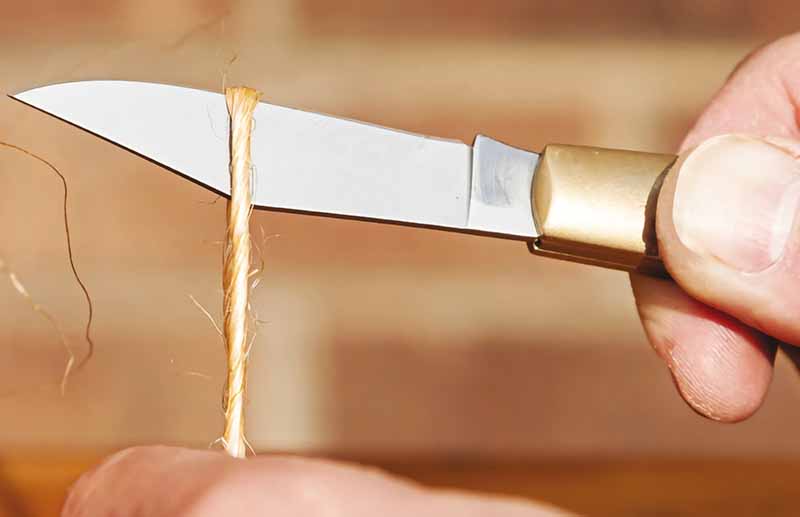

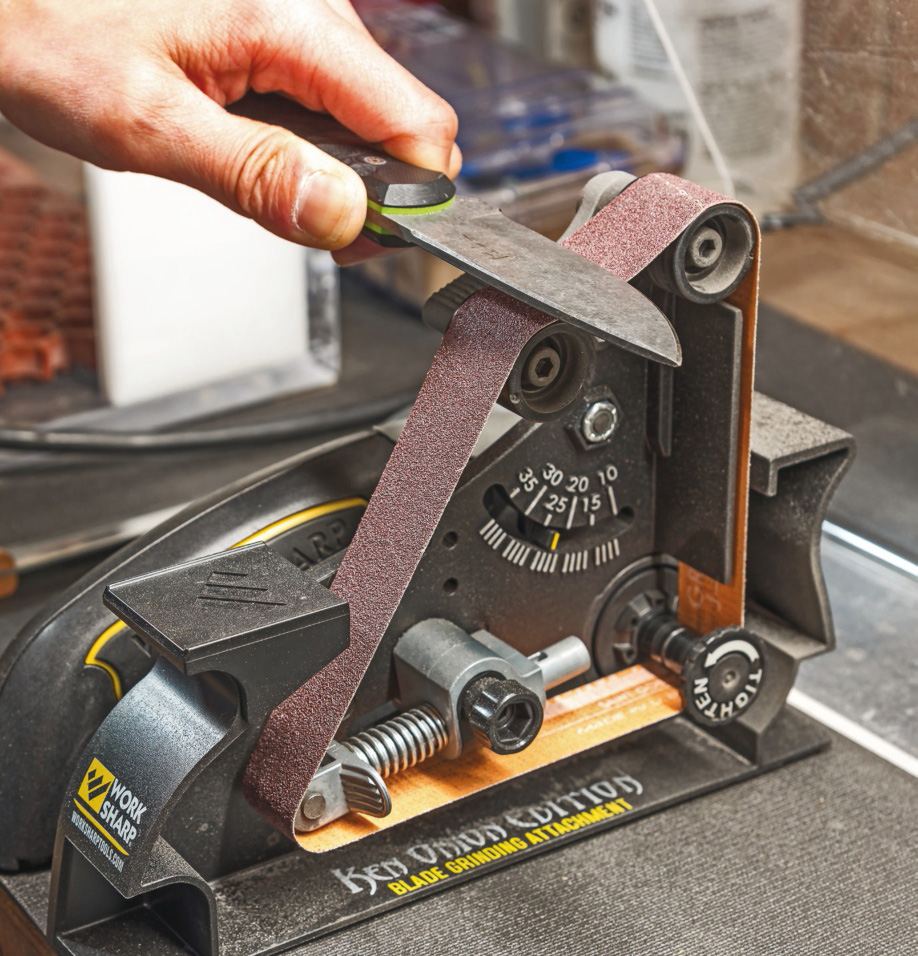

You can work 1095 to death, then take your favorite sharpener and put an edge right back on it. Try doing that with CPM S30V stainless! Because of 1095’s tendency to rust, you must maintain it more than stainless. Many 1095 blades sport a coating that protects most of the surface except the edge. If you’re not careful, corrosion can begin at the edge then travel up underneath the coating. Consequently, in a wet environment keep a light coat of oil on the blade. If you wash the knife, towel dry it carefully and let it air dry, too. As for some of today’s top models in 1095, check these out.

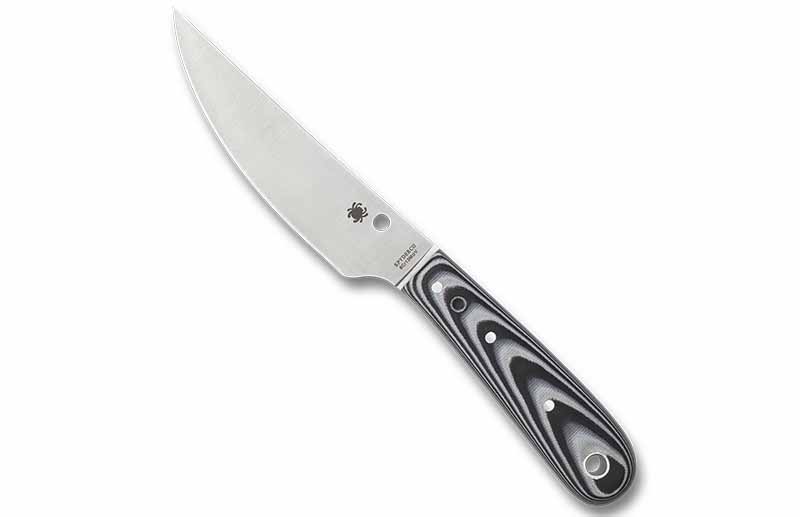

Condor Tool & Knife Bush Slicer Sidekick

The Bush Slicer Sidekick from Condor Tool & Knife is a small, lightweight fixed blade designed to handle intricate food prep tasks similar to those paring knives address. It also functions as a stand-alone tool for bushcraft, as well as day hikes and such.

The 6.4-inch modified wharncliffe blade on this high-carbon steel knife has a defined tip for intricate cutting tasks, but also enough sharpened real estate to get work done. Close to 9 inches overall, the knife carries well and is neither too big nor too small for many food prep and camp chores. The black Micarta® handle is ergonomically shaped for maximum user comfort. The sheath is well designed, too. One of the few hybrid-constructed models employing Kydex and leather, it is quite user friendly. You get the rigid protection of Kydex along with the carry versatility a leather loop offers, allowing the sheath to move somewhat while on the belt. The gray Kydex complements the handle’s appearance.

The Bush Slicer Sidekick is built extremely well, with high quality fit and finish. The edge is razor sharp out of the box. The standard Condor blade finish is two tone, with the darkened heat-treat scale finish on the flats and machine satin on the bevels. The cutting edge is tilted up a bit in relation to the handle, giving more hand clearance on a flat surface. The way the blade profile tapers toward the tip is smart as well, giving the knife the ability to tackle finer cutting tasks. Another nice feature is the 90-degree blade spine for use in conjunction with a fire-starting ferrocerium rod.

The flat-ground blade thins the edge well so it sails through a variety of materials, yet is thick enough for durability. The tip is controllable for fine and precise cutting. Integral front and rear guards prevent unwanted hand movement in either direction. However, those with larger hands may find the grip a bit small. It also lacks a lanyard hole. At a manufacturer’s suggested retail price (MSRP) of $119, the Bush Slicer Sidekick represents excellent value in an expertly crafted using fixed blade. County of origin: El Salvador.

TOPS Knives 3 Pointer

The TOPS Knives 3 Pointer might be the smallest of the test bunch, sporting a 3.1-inch blade and 6.6-inch overall length, but also has the most options. It comes in three handle choices—black Micarta, tan Micarta and skeletonized. In addition, each model comes with two modes of carry. Straps screwed to the sheath permit horizontal belt carry, and a chain provides neck carry (just remove the belt loops). The options might make you consider the 3 Pointer to replace a folder for EDC.

The high-carbon steel knife’s heart and soul lies in its deep-bellied drop-point blade capable of field dressing game, doing chores in camp, etc. Black Traction Coating helps ward off rust. It is a very durable coat that withstands frequent heavy use.

The handle is particularly interesting. The pronounced finger groove can lock into your grip, with the rest of your fingers falling into place on the tapered handle. Unlike other fixed blades of this size, the handle isn’t blocky or bulky, which allows it to be carried as a belt or neck knife. We tested the tan handle version, which has a nice contrast in appearance to the black blade. Three large traction notches accept a thumb comfortably on the spine to exert control and pressure. The red liners provide a subtle pop of color contrast.

The Kydex sheath is well made and designed with an integrated thumb rest that lets you grip the knife handle and push out, easily popping it free of the sheath. The feature is very well thought out and not found on many knives.

I carried the 3 Pointer mainly as a neck knife for the evaluation. Neck knives are a love ’em/hate ’em proposition. If you want to carry a smaller fixed blade in a discreet manner this is the most viable option, as neckers conceal easily, even under a plain T-shirt*. They also work well with polo-style and button-down dress shirts. And when you start layering as the temperatures drop, neck knives carry well under a hoodie and other cold weather wear. The flat handle profile enhances discreet carry without printing underneath the aforementioned T-shirt. I like how the shape and contours help you obtain a very secure grip.

The drop point blade is usually my favorite when it comes to straight knives due to its versatility. The belly allows the blade to tackle sizeable cutting tasks while remaining easy to carry. If you prefer taking a small fixed blade into a restaurant to substitute for the knives provided, the 3 Pointer is low profile enough to cut food without attracting unwanted attention. The TOPS 3 Pointer in tan Micarta has an MSRP of $125—an excellent deal for a USA-made sheath knife.

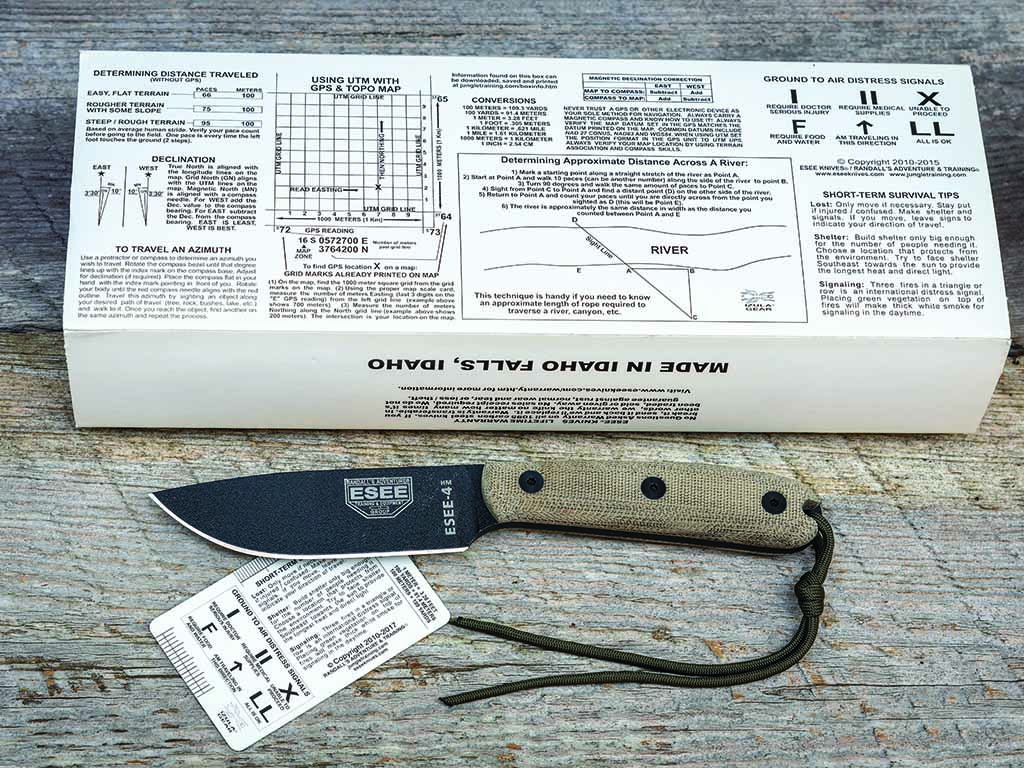

ESEE 4HM

The ESEE 4HM blends toughness and cutting efficiency in one package that carries easily and is built for extended use. The 4.3-inch blade has a generous belly for field dressing, food prep and some bushcraft. Overall length is just short of 9 inches. Blade thickness is .1875 inch and the flat grind is robust for long-term durability, though thin enough for slicing. The blade has a black powder coat to protect it from the elements.

The Micarta handle is beefy but rounded in the right places, and fills your hand without generating hot spots. The Micarta is fastened to the tang using three sets of flat-head Torx screws. A lanyard hole comes with a length of paracord, making the 4HM easy to extract from the well-made, sewn pouch sheath of brown leather. The knife sits down in it securely but loose enough so it comes free smartly when needed.

It is a great all-around fixed-blade high-carbon steel knife. The blade and handle shapes are universal and work well in most scenarios. The drop point shape is also a great scraper, if needed. The fat handle cross section gives a reassuring grip, as opposed to shapes that might be comfortable but, due to being too thick, are not as secure in the hand. If you enjoy hunting, camping and hiking and use a fixed blade a lot, this is the knife you need. Country of origin: USA. MSRP: $178.

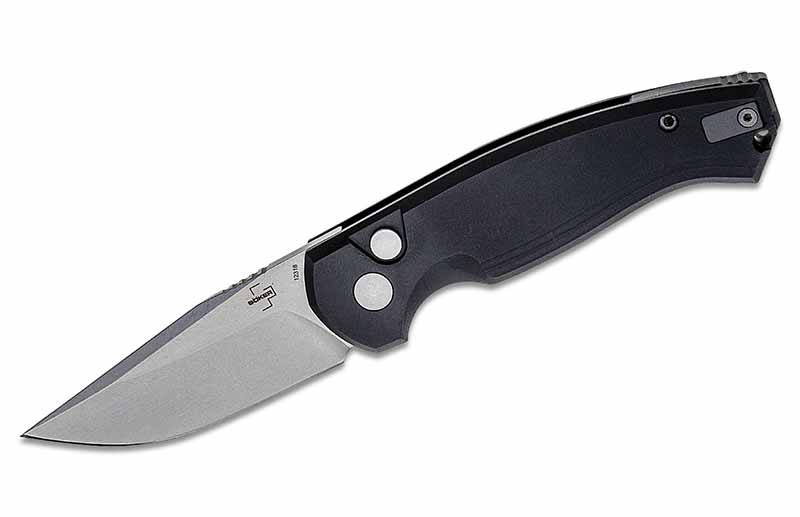

KA-BAR BK18 Harpoon

The BK18 Harpoon is Ethan Becker’s latest design for KA-BAR. The 4.5-inch drop-point blade offers plenty of length for food prep and outdoor tasks. The prominent harpoon-style swedge projects attitude. The ergonomic handle features multiple swells for comfort and a non-slip grip. A palm swell fills your hand and provides excellent stability and control. The harpoon blade forms an integral forward guard, and the slightly dropped handle butt helps capture your hand. There’s an oblong hole for a lanyard.

At 9.3 inches overall, it’s a great mid-sized sheath knife. The blade belly slices easily, while the handle provides the ultimate in control. Traction notches on the spine allow you to choke up. The sheath is a molded Celcon® polymer with a heavy duty nylon webbing belt loop. The knife fits/clicks in to avoid inadvertent loss. A nifty feature is the two molded-in vent channels that reduce moisture by allowing inside air flow. A secondary webbing button snap secures the handle in place, though the way the knife clicks tightly into the sheath, I cannot imagine it popping loose accidentally. The belt loop also can be re-mounted to set the knife up for left-hand carry.

One thing many remember about seeing their first Becker design is the chunky handle design. As awkward as it may look, it works. No matter the model, basically the same handle shape is used, a hallmark of Becker designs. The BK18 Harpoon has the same configuration but it’s slimmed down considerably. It’s comfortable for extended use and helps keep your hand in place with no awkward sliding in either direction. It also helps prevent the handle from rotating in your grip.

Speaking of handles, there is an optional upgrade. The tan Micarta kit, which replaces the stock molded grip, is $35. It’s worth it. The Micarta has a nice grab-you-back feel that holds well even with wet hands—a feature the stock handle somewhat lacks. MSRP is $120, also not bad for a USA-made fixed blade.

Also Read:

- Ballistic Knife: The Most Illegal Knife In America

- Spike Tomahawk Reviews: RMJ Tactical, Cold Steel, SOG, Browning

- A Quick History Of The Tomahawk In The United States

- 11 Tips For Starting A Knife Shop At Home