Survival Knives Need To Be Versatile, Durable, And Strong. These 10 Blades Are Everything You Could Ask For When In A Sticky Situation

A survival knife is most often a heavy-duty fixed blade built to withstand hard use in multiple roles, generally in the wilderness. It must be able to whittle, carve, chop, slice, and maybe dig. It also holds down the regular duties of a knife and assists in all cutting chores. Additionally, if your back is up against a proverbial wall, it should have the chops to serve as a weapon.

Survival Knife Features

When looking for a quality survival knife there are four key things you need to look for: the quality of the steel, handle material, the robustness of the guard, and the caliber of the sheath.

Steel

As with all knives, it all starts with the blade steel. Carbon steel and stainless steel are both used with survival knives, both have their pros and cons.

Carbon steel requires a bit more diligence to maintain and keep from rusting but offers ease of in-field sharpening. Stainless steels are more resistant to the elements and, if you spend the money, the higher grades offer enhanced edge-holding capabilities.

Handle

Next, you want to look for a knife that has a comfortable handle. This is key, given you’ll use the knife for extended periods of time.

What you need to consider is:

- How is the handle contoured?

- Does it feel good in your hand?

- Is it made of synthetic or natural handle materials?

Personally, I would stay away from leather because of its nature to soak up moisture. I would look to some sort of synthetic like G-10, micarta, or reinforced thermoplastic. These synthetic materials are dimensionally stable and are not affected by changes in temperature, humidity, and exposure to UV.

Guard

The guard keeps your hand in place by preventing any forward movement while the knife is in use. You might be able to wrap a finger around the guard to further choke up on the handle for extra control during cutting or whittling.

Given survival knives are tasked with a number of rough-and-tumble duties, it’s wise to consider an ample guard—at least for the sake of safety.

Sheaths

Not as sexy, sheaths are equally as important as the knife itself. Essentially, the accessory helps protect the knife when not in use, as well as provides a means of portability. Most attach to a belt or MOLLY field, in the case of a backpack.

Materials such as Kydex provide the best options. Why? The thermoplastic is light, form-fitted to the knife blade, and impervious to the elements. What more could you ask for?

You might also notice some sheaths are made of ballistic nylon with a hard plastic liner inside to prevent the knife from destroying the sheath. These are also a good alternative and are more cost-effective along with being fairly weather resistant.

Leather and other natural materials on the other hand, generally ware out quickly with active use. Worse yet, they retain moisture, which can be hell on a blade—especially a carbon-steel blade.

What To Avoid When Buying A Survival Knife

Yes, survival knives come with a host of features but there are some that are useless or worse. These three features aren’t worth the price.

Spine Serrations

Ugh … serrations on the blade spine. Admittedly, some like having serrations as a cutting option for certain materials. However, generally blade spine serrations offer limited use at best and are more of a hazard because of how close they are to your hand.

Honestly, if you need serrations, bring along a serrated folding knife like a Spyderco Delica or Endura. Problem solved.

Blade Holes

Alright, these serve no function at all, except they make the knife look cool. That might be alright for a collection novelty, but not a wise course when in the wilds.

Worst of all, the holes in the blade do nothing but weaken it. Stay away from them.

Odd Blade Designs

Like blade holes, they may look cool but rarely do they enhance the function of a survival knife. We’re striving for utility here, not unique looks.

Stick with the traditional blade styles—spear point, clip point, and drop point. These are proven and do the job perfectly.

10 Best Survival Knives

There are countless makers producing dozens of different survival knives. These 10 stand out from the pack for either their features, their toughness, or their price.

Mora Garberg

Mora is the king of value when it comes to inexpensive survival knives. Most come in at less than $50, but you are hardly compromising in quality.

I personally favor the Garberg, which has a 4.3-inch carbon-steel blade with a Scandi grind and a full tang through the handle.

The blade spine is at 90-degree, designed specifically for use with a ferrocerium fire starting rod. The dual-molded handle is made from weather-resistant polyamide. Its unique Multi-Mount sheath is included and fastens the Garberg to an ATV or snowmobile, as well as a belt.

It’s a tough too, so you are getting a lot of knife for your money. It’s made in Sweden and sold worldwide.

MSRP: $111.99

Cold Steel 49LCK-DTBK SRK Survival Rescue Knife

A long time classic of the Cold Steel product line, this knife is a proven, solid performer in the outdoors. Its 6-inch clip point blade is made of SK-5 carbon steel and attached to a textured desert tan Kray-Ex rubber-like handle that is textured for a great all-weather grip.

The blade has a black, epoxy-coat for low visibility and high weather resistance. And its single lower handle guard indexes to the grip.

The SRK is suitable as a hunting knife, survival knife, or even a fixed blade for military use. It’s a very handy design that excels at camp utility and food prep.

MSRP: $61.95

Gerber Ultimate Survival

This is an all-business design from Gerber Gear.

The stainless-steel blade provides ample resistance to the elements and holds an edge well. Its drop point design has plenty of belly for slicing and the partial run of serrations adds a bit more utility to the knife.

The handle material is rubber for an excellent non-slip grip. The large finger recess indexes your grip and allows for maximum user comfort. The butt cap of the handle is steel and can be used as a light-duty hammer when needed.

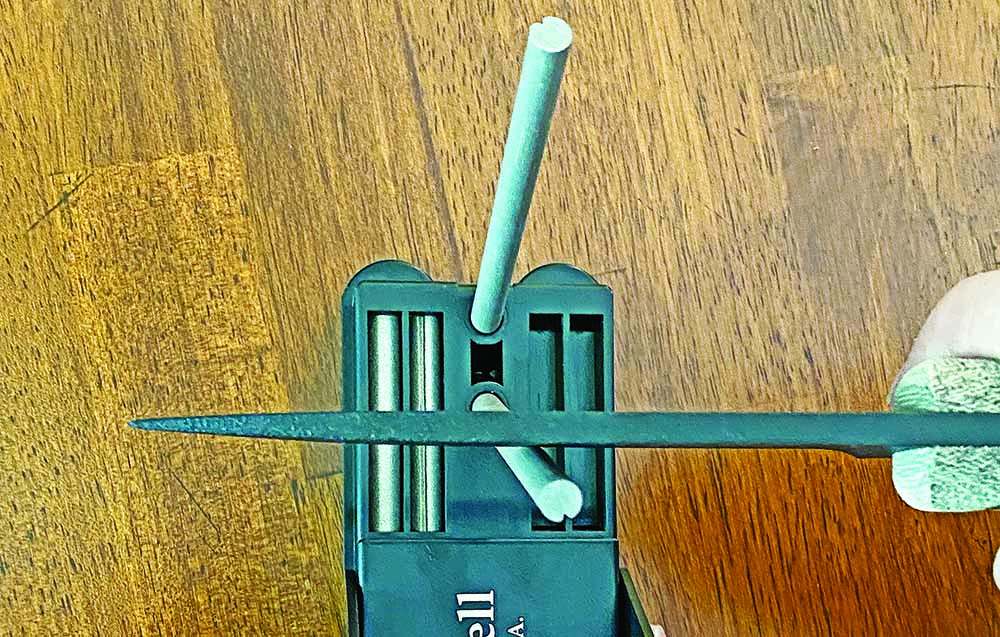

The hybrid nylon webbing and molded plastic sheath is durable and includes a fire starter and blade sharpener.

Superior handle ergonomics paired with a useful blade shape and partial serrations are what makes this one a winner.

MSRP: $62

Benchmade Anonimus 539GY

This is Benchmade‘s new high-end fixed blade, with some excellent features. First and foremost, high-end CPM CRUWEAR tool steel, which provides ultimate wear resistance and edge retention.

The flat ground, 5-inch long drop point blade offers plenty of belly for effective slicing and cutting. Notches on the blade spine provide a secure non-slip grip for your thumb or index finger, and the single, lower guard keeps your hand in place.

The Anonimus is secured by a molded Boltaron belt sheath very similar to Kydex. The G-10 handle sports machined-in texturing for a non-slip grip.

MSRP: $290

CRKT Catchall

Designed by custom knifemaker Russ Kommer, the Catchall by CRKT is on the heavy-duty side of things.

This broad chopper-style blade measures 5.5 inches in length and has a sheepsfoot-style blade. The blade is made from 8Cr13MoV stainless steel, which holds a decent edge and provides excellent corrosion resistance.

The ergonomic handle features finger grooves for a secure hold, and the handle material is rubberized glass-reinforced nylon. The Catchall might not be the type of knife for lighter cutting jobs but rather more intense tasks, such as chopping and baton work for splitting kindling for firewood.

The Catchall would be great paired with a lighter duty survival knife dedicated to finer chores. The sheath is a glass-reinforced nylon variation with ballistic nylon webbing belt loops. A single webbing strap with button snap holds the knife inside the sheath securely

MSRP: $79.99

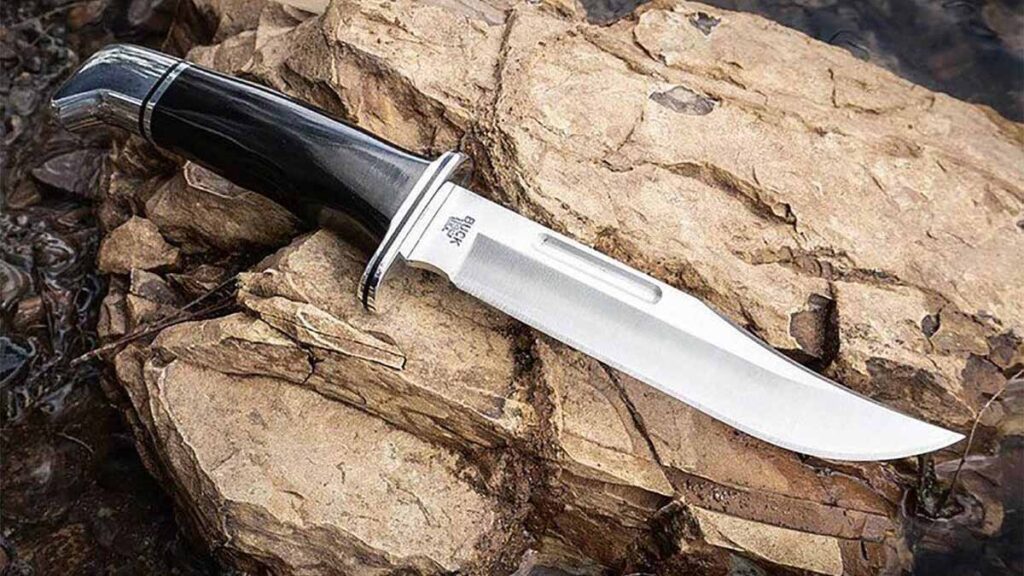

Buck Knives 119 Special

This is one of Buck‘s signature fixed blades. Sporting a 6-inch-long Bowie-style clip point blade made from 420HC stainless steel, the 119 Special has found its home in the outdoors with hunters and outdoorsmen alike.

The handle is a black phenolic resin, which is durable and highly weather resistant. And the knife comes with a black leather sheath. The handle butt cap and double guard are made from aluminum. The 119 Special is capable of handling both camp utility chores like whittling and baton work. The piece is also balanced enough to handle food prep.

MSRP: $96

Condor Knife and Tool Pack Golok

The Pack Golok from Condor Tool And Knife is a devastatingly effective chopping tool, with its 11-inch long, convex-ground 1075 carbon-steel blade attached to a rounded walnut wood handle that adds tons of user comfort and control.

The upswept blade profile adds forward weight to the balance, which is key to the performance of this knife. It can take down saplings with ease and slay its way through weedy growth like a machete. It also handles baton work like a champ.

The Pack Golok is much more than just a machete and more useful than one, and it comes with a leather sheath and swivel belt loop for portability.

MSRP: $101

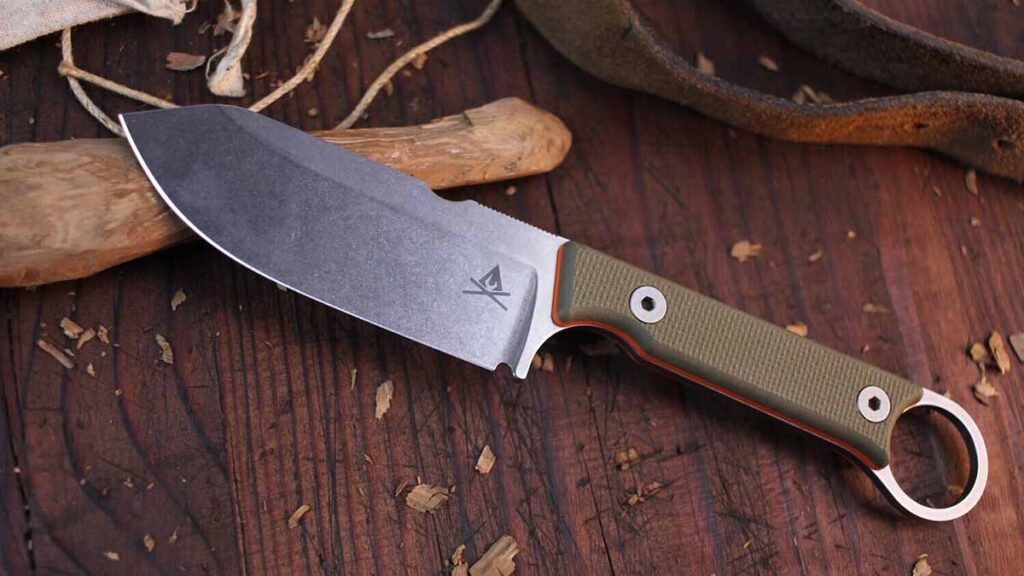

White River Knives’ Firecraft FC3.5 Pro

The Firecraft FC3.5 Pro from White River Knives has a 3.5-inch-long spear point blade ground from high end CPM S35VN stainless steel. The handle is coarse-textured G-10 and comes in a choice of orange, black, or OD green.

Regardless of which handle color you choose, you are getting a no-nonsense fixed blade able to handle a wide variety of tasks at the campsite or out in the wilderness.

The notch in the blade spine allows for easy use with a ferrocerium fire starter rod. The wide blade can handle food prep chores and camp utility tasks. The finger ring allows you to dangle the knife from the pinky finger, keeping it close at hand, while retaining the ability to use your hand to grab or hold items.

The S35VN steel holds an edge well and is able to power through tough cutting. Each knife comes with a molded Kydex belt sheath.

MSRP: $160

RMJ Tactical Combat Africa

The RMJ Tactical Combat Africa is one serious piece of bladeware that can serve as a survival or military knife. It’s 7-inch-long blade is made from 80CRV2 tool steel. The .25-inch thick stock means this knife can withstand some serious use and some prying as well.

The clip point shape allows for optimal penetration, with some belly for slicing applications. The 3D machined G-10 handle has diagonal flutes, adding hand traction and channeling water away for a comfortable grip.

Furthermore, the lower hand guard and blade spine thumb ramp help to keep your hand safe from sliding forward. The knife is capable of chopping, prying, batoning, and slicing.

The knife is a bit on the steep side when it come to price. But in return you receive the superior engineering and craftsmanship for which RMJ Tactical is known.

MSRP: $395

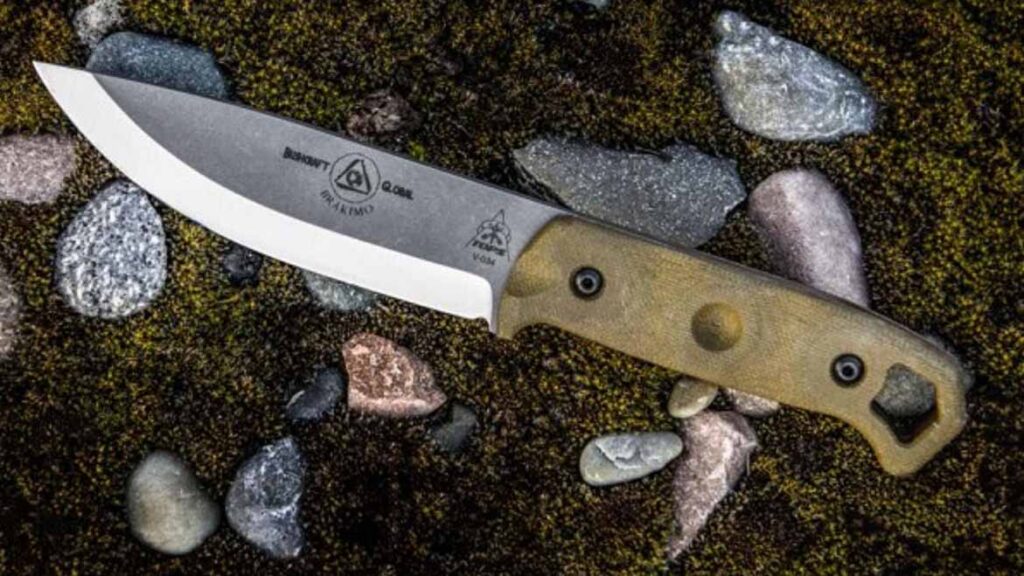

TOPS Brakimo

The TOPS Brakimo was designed by noted survival expert Joe Flowers, who owns and runs Bushcraft Global, a renowned survival school.

Flowers designed this knife to be a backup to a machete or a main camp knife. The 5.25-inch drop point blade is made from 1095 carbon steel. It is wide and sports a Scandi grind for optimal edge geometry for camp tasks. As a bonus, the carbon steel is easy to sharpen in the field.

The knife is rather weighty for its size at 9.4 ounces. The sculpted handle is made from OD green canvas micarta for a comfortable and nonslip grip. The handle’s downward turn at the butt allows you to choke up at the end of the handle during chopping. Each Brakimo comes with a molded Kydex belt sheath with large metal clip for easy belt attachment.

MSRP: $224.95

Read More

- 4 Excellent Bushcraft Knives

- Best Gut Hook Hunting Knives

- Best Skinning Knives