Quick Tips

- Choose a knife that isn’t too small for anticipated tasks, but not too large to carry comfortably

- Buy inexpensive ($25 or less) knives if you don’t care that they get lost or broken

- Pay at least $75 for an average quality EDC

- Better performing knives start at $100

- Handle the knife before buying if possible

- Avoid gimmicks

- If you can’t figure out how to open it by looking at it, it’s not the right fit

Top 10 Things to Consider in Buying an EDC Knife

- Quality materials

- Top blade steel

- Maker/manufacturer and customer service

- Application or cutting tasks it will perform

- Price point

- Type of lock or mechanism

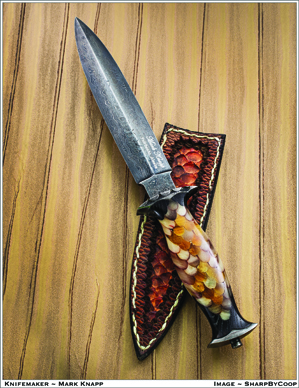

- Design

- Ergonomics

- Size and weight

- Ease of carry

The Best Everyday Carry Knives for the Money

How do you get the best everyday carry (EDC) knife for your money? Will a $25 knife from a big-box store suffice? Is there such a thing as a quality $25 knife, or will it be necessary to spend $100, $500 or $1,000 for a blade? BLADE went looking for answers.

Buying EDC Knives Is Like Buying Cars

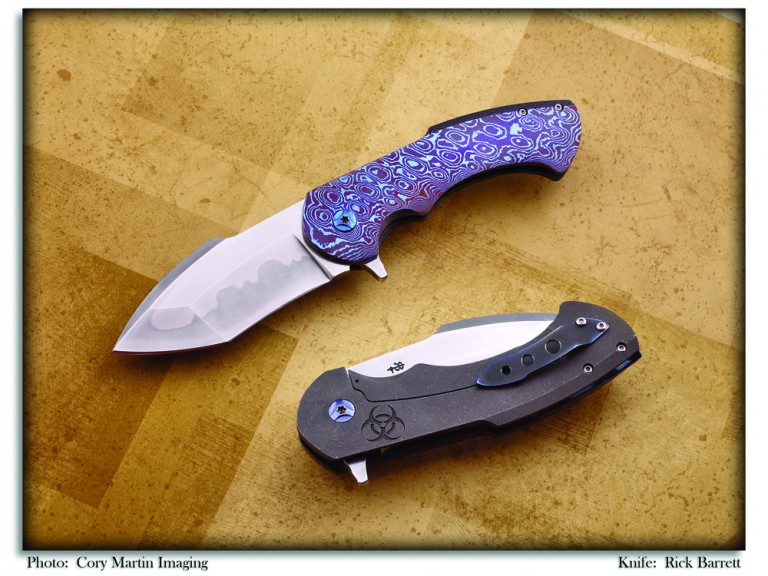

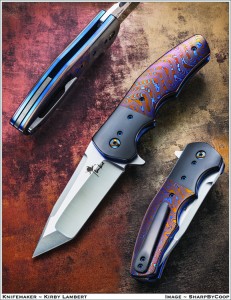

designs, thick frames, solid locks and easy-opening, high-end

steel blades.

“Directing a customer to an EDC knife is somewhat like pointing them toward an everyday car. Some think a base economy model suits them well, whereas others want a high-end luxury model,” says Mike Dye of New Graham Knives in Bluefield, Virginia.

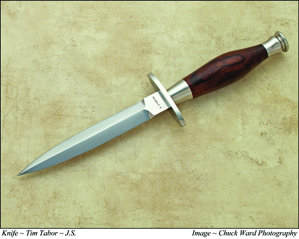

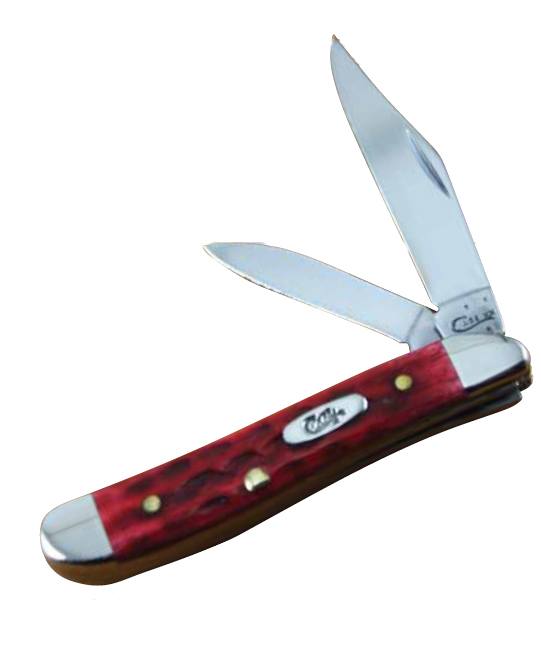

“Obviously, a good mid- or high-end blade steel is paramount. And the feel of the knife in the hand—it must ‘fit’ the user,” Dye explains. “Different handle materials can make a world of difference in the feel of the knife. Micarta, G-10, smooth or worked titanium, stainless steel, bone and stag—these choices are of a personal nature.”

Not Too Small, Not Too Large

Though Dye says everyone likes something different, there are keys to finding the right everyday carry knife. One tip, he notes, is to choose a knife that is neither too small for the tasks it might encounter on an average day, nor one too large to carry daily.

Matt Salazar, store manager for House of Blades, agrees and even has a suggestion as to blade length, saying a 3- to 3¾-inch blade is ideal for an EDC knife. He mentions modern blade steels such as CPM S35VN or M390, as those that are more than adequate for everyday cutting tasks.

“Stick with a good, quality brand that has a track record of great customer service,” Salazar recommends. “G-10 and aluminum are great options, as far as handle material goes, although titanium and carbon fiber are widely available if you want something a little more high-end.”

When Does $25 Cut It?

Dye says a $25 knife might be the perfect choice for a farmer, miner or auto mechanic who uses the knife for any task that comes up.

“If broken or lost,” he states, “it’s easier to repurchase a $25 knife than it is a more expensive piece. For others who are less likely to overwork or ask a knife to do chores it’s not designed to do, a higher-end model with ‘prestige’ might be in order.

“As for a quality $25 knife,” Dye continues, “yeah, they’re out there. Over 40 years ago, when I started selling pocketknives, the China-made knives were a joke. That is not the case today. Some factories in China are producing amazingly high-quality knives at popular prices.”

Dye says such companies as Kershaw and Spyderco (the latter specifically in its byrd line) market knives manufactured in China with great success.

“Ontario and ESEE have great EDCs at a reasonable price,” he notes, “and they offer support for warranty issues.”

Disadvantages of Budget Knives

Salazar poses the question, “How long do you want the knife to last?”

“In my opinion,” he says, “you are going to be really hard-pressed to find a quality knife for $25. I will say that Kershaw makes great knives in every price point, but I’d also say that $75 to $100 would get you an excellent EDC knife that should last you many years with proper use. You can certainly spend more, if your budget will allow.”

Many steels in lower-end knives will not retain a sharpened edge for as long as high-quality blade steels, which means more frequent sharpening and a shorter life expectancy for a knife.

“Steel quality, in general, would be the biggest drop-off in opting for a lower-end knife,” Salazar explains. “Inferior edge retention is likely the most significant downfall, when purchasing a budget knife. After all, it’s a cutting tool.”

Higher Quality Equals Better Performance

High-dollar production knives, such as those available from Chris Reeve Knives, Hinderer Knives and Zero Tolerance, exhibit quality craftsmanship, better steel options and stricter quality control.

“Look for solid lockup, if it’s a locking folder, smooth action and overall quality construction,” Salazar remarks.

“Generally, when the customer has tired of the off brands and low-end offerings at the big-box stores, they come to me asking for a quality knife,” Dye relates. “That said, most of our walk-in folks have a ceiling of around $50 to $100, and there are dozens of excellent choices in that range.”

Tangible advantages to higher-end knives include titanium versus pot-metal knife frames, and handle materials such as Micarta, carbon fiber and natural bone versus plastic grips.

“Fit and finish on higher-end knives are rightly expected to be superior,” Dye states. “A customer will have a good experience with a knife that sharpens easily, cuts well and retains an edge. With high-end EDCs, you start to get into quality frame materials, better steels with superior heat treating and locking mechanisms that hold greater tolerances.”

Handle the Knife Before You Purchase It

“If possible, handle the knife before purchasing it,” he suggests. “Look for lack of blade play on folders, both horizontally and vertically, and examine lockup. Look at fit and finish. Well-made knives at any price will show well in those areas.”

Dye says, “I tend to steer customers away from fancy opening mechanisms, unorthodox locking mechanisms and knives that have obvious marketing gimmicks associated with them.”

Materials to Consider

Stainless as opposed to high-carbon blade steel is a consideration for Julie Maguire and Ryan Thompson of Arizona Custom Knives.

“In order to be an EDC candidate, a knife should have a high-quality stainless blade. There are more stainless steels to choose from today than ever before. Do your research and choose the one that fits your cutting needs,” Maguire says.

“Finding a knife with durable handle materials is also important,” Thompson imparts. “Titanium, G-10, Micarta and carbon fiber are all great options that hold up well in various conditions.”

Conclusion

One thing is for certain. As knife designs, blade steels, materials and mechanisms improve, the perfect EDC will always be a moving target.

Keep Reading

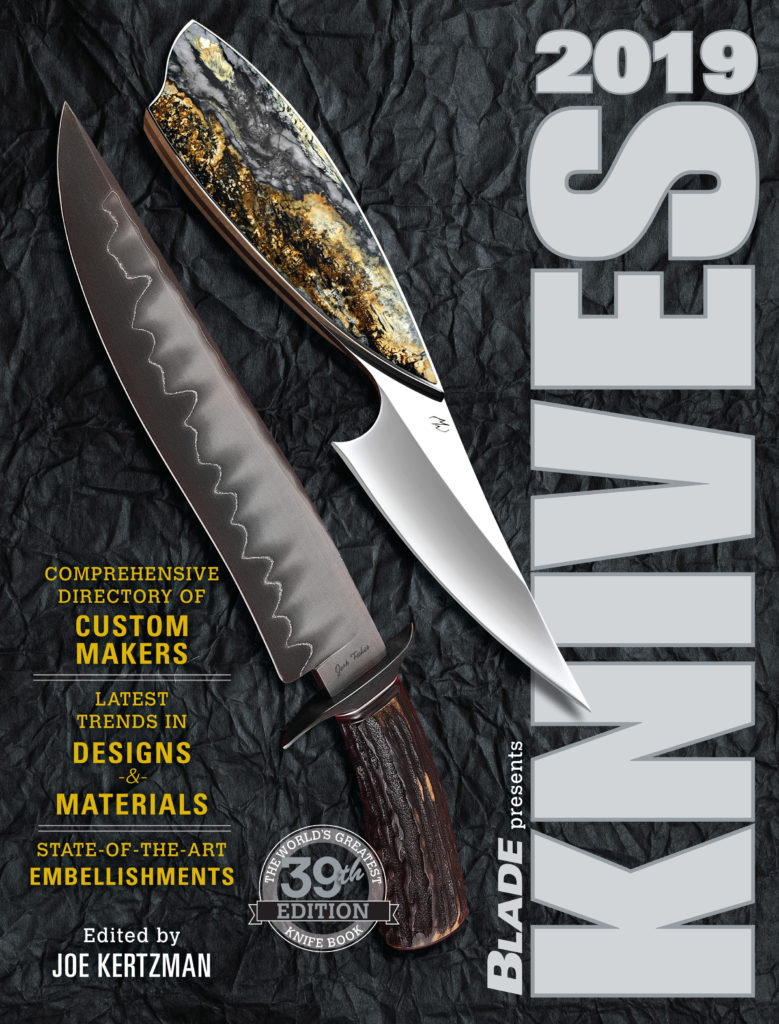

This article is excerpted from KNIVES 2019, the world’s greatest knife book. Pick up a copy of this essential knife collecting book here.