The knifemakers of Argentina and Brazil have revolutionized the world of cut.

The language of custom knifemaking and bladesmithing is universal, so, logically, the appeal of the industry would have global reach. Through the years, such has been proven in the work of gifted artisans around the world, and those from Latin America have gained increasing attention. The quality of their forged steel, the fine lines of their folders and fixed blades, and the attention to detail in their finished work have created a buzz.

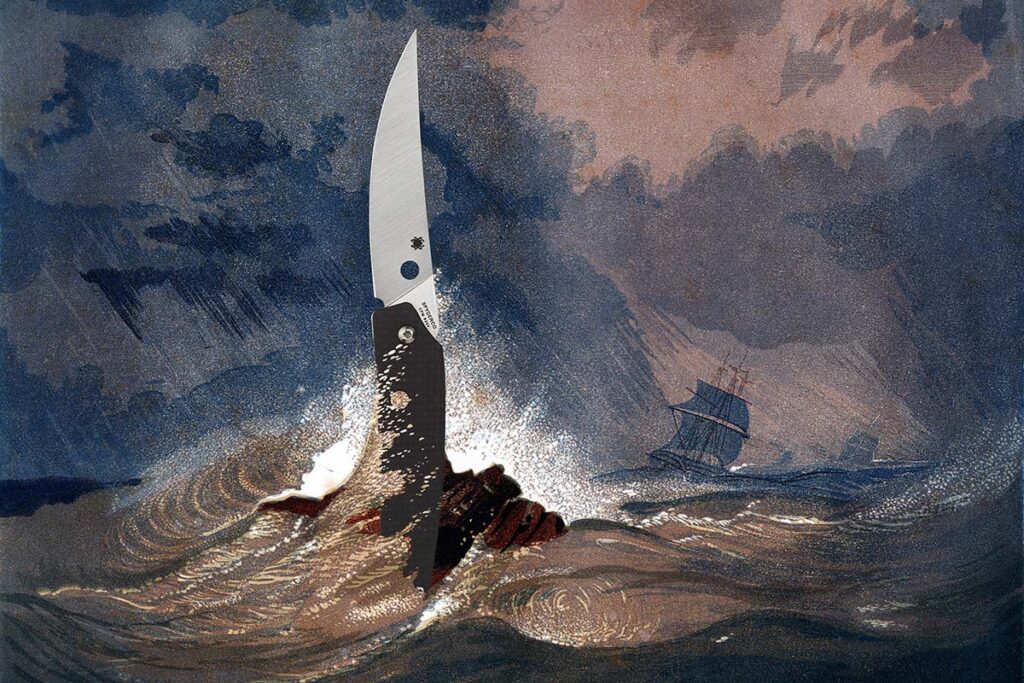

The impact of Brazil and Argentina especially has been noticeable at the BLADE Show and elsewhere in recent years. Argentine winners in the BLADE Show custom knife competition include Claudio, Ariel and Marcelo Sobral, Mauricio Daletzky and Javier Vogt, while Brazilian winners include Fabio Barros, Gustavo “Gus” Cecchini and Franco de Souza, the latter whom recently copped multiple knife judging awards at this year’s BLADE Show Texas. Cecchini, meanwhile, pulled a rare double at last year’s BLADE Show, winning for Most Innovative Design in the custom knife competition and the BLADE Magazine 2023 Knife Collaboration of the Year® with WE Knife for the Solid folder.

Like their European, Asian and North American counterparts, bladesmiths and knifemakers from Latin America are acknowledged by manufacturers, purveyors and the buying public as among the best in the world. Their stories validate their commitment and emerging success.

Ricardo Vilar

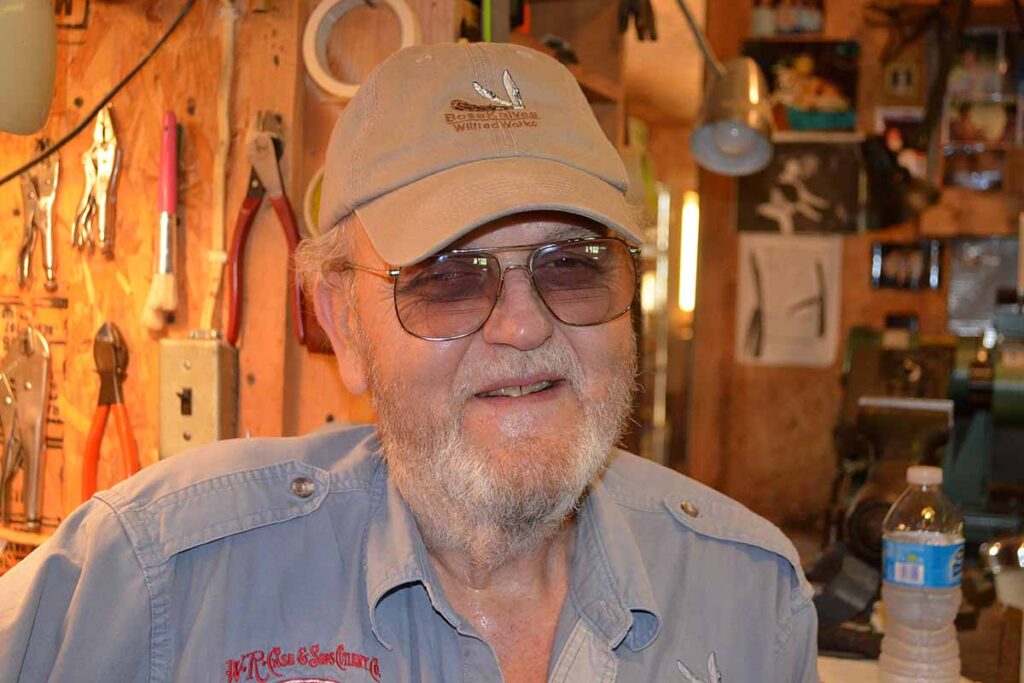

One catalyst for the growth and resulting excellence among Latin American artisans is ABS journeyman smith Ricardo Vilar, a native of Brazil who relocated with his family to Arkansas several years ago. Vilar wanted to be the best, and so he sought out the counsel and advice of the best. He was so thoroughly committed to bringing award-winning bladesmith Jerry Fisk to Brazil for some learning and instruction that he was willing to sell his car to make it happen.

“It was in 2000 that I started exchanging messages with Jerry because I had come to the BLADE Show with one of my friends and talked to him about doing a hammer-in in Brazil,” Ricardo remembered. “Jerry came to Brazil in 2001 and had a meeting with 14 knifemakers and bladesmiths at my shop. We had nine dates with Jerry at my shop, and then after that the knowledge began to spread.”

Vilar and Fisk developed a close friendship along the way, and Ricardo has made the most of his innate talent and the skills he has sharpened with help from Jerry. Living within an easy drive of one another, Ricardo and Jerry are regularly in touch. In 2020, Ricardo won first place on an episode of Forged in Fire as a television audience witnessed his prowess. He also became involved with a Latin American version of FIF titled A Challenge Under Fire. In 2021, the two also embarked on a joint venture called FAV (Fisk and Vilar) to produce a limited number of collaborative pieces, up to 25 annually, for the collector market.

“After Jerry came to Brazil, we started sharing information and that sharing is very important,” Ricardo added. “We have had guys from Argentina come to meetings as well, and we like to ‘walk together’ in getting better.”

When Fisk arrived in Brazil for the first time, he informed the gathering that they would be better served using a gas forge. When the attendees were skeptical, still using coal and charcoal, he told them to have open minds.

“Ricardo and I went down to a junkyard and got what we needed,” Jerry recalled. “We set up the forge and made damascus and opened up everybody’s eyes. I also found out that bladesmiths from the different states in Brazil did not really share information with one another. When they told me that, I started to pack my bag. When they asked what I was doing, I told them that if they didn’t share information I was going home. ‘If you won’t share with each other, then why should I share with you?’”

The message was heard loud and clear. From there, the Brazilian bladesmiths and knifemakers made steady, significant progress, right along with others from neighboring countries in Latin America. “The intent was to show the rest of the world what they were capable of doing,” Jerry said. “I went there for a few years to teach them and show them a few things, but then there has to be a line where you are no longer teaching but cheerleading. I would cheerlead with them when they asked a question and say, ‘Yes! Yes! You’re doing it the right way!’”

Ricardo looks back at the investment of time and money that really helped bladesmithing and custom knifemaking to take off in Latin America. “I was willing to sell my car to buy Jerry’s plane ticket,” he laughed, “and I started telling other knifemakers that he was coming to Brazil and that they should come to my shop to see him work. He is my mentor, and I am still inspired by his work.”

For Fisk, teaching and cheerleading come naturally and fulfill an obligation to help others.

“Some of them call me the father of modern knifemaking down there,” he commented, “but what it amounts to is that my first students have had students, and it has just multiplied, so in a way I have multiple grandchildren and great grandchildren in bladesmithing and knifemaking.

“I remember telling them that if they wanted to show their knives in the U.S., they had to go above and beyond what others might do. I said, ‘Others will assume that your work is not as good as what they have been seeing. So if their knives cut through two 2x4s, make yours cut through 10. Make your knives cut more ropes than theirs. Dig deeper and go further!’”

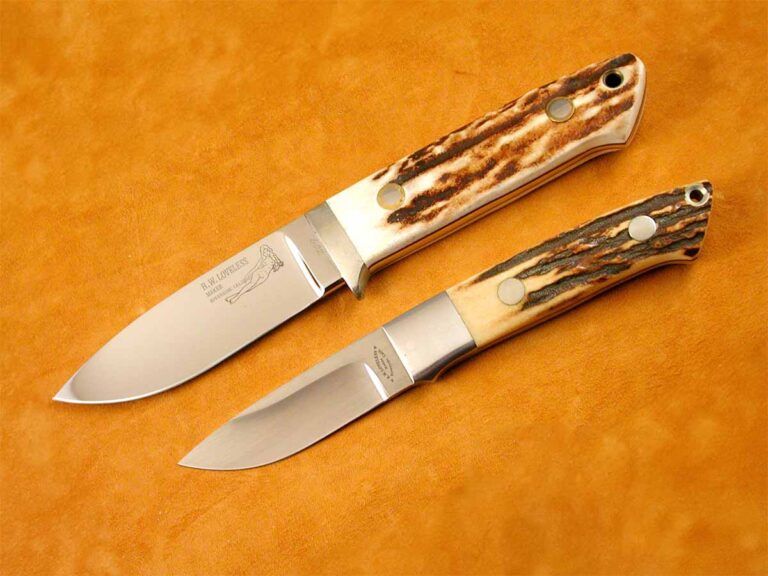

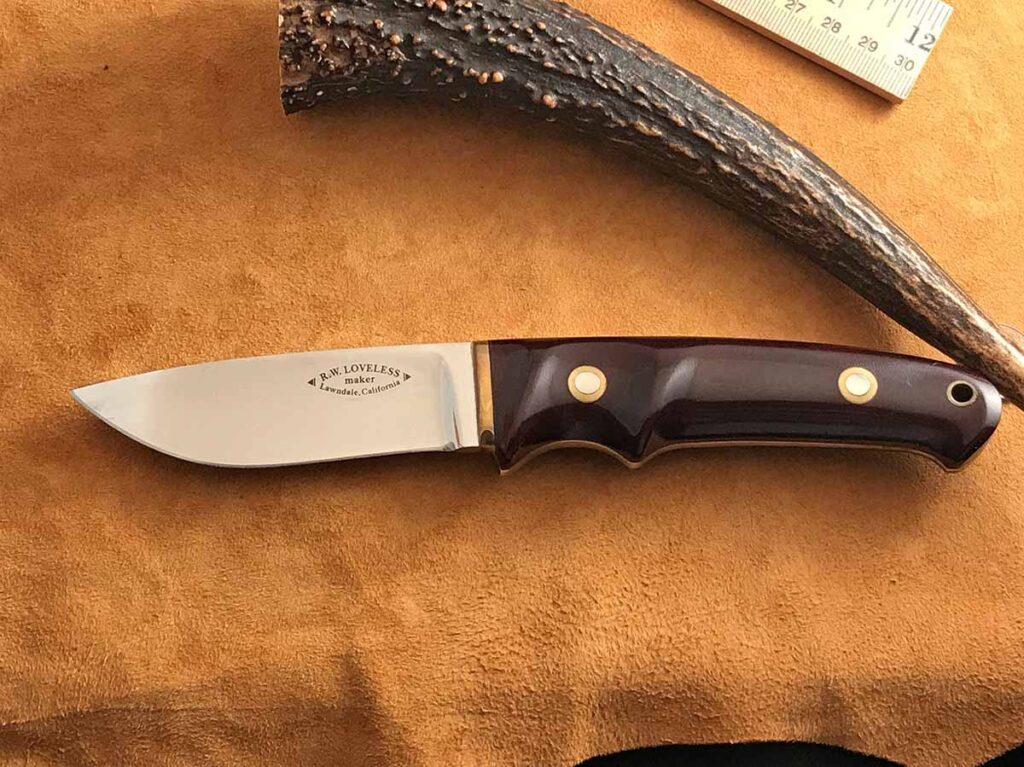

Jerry also singles out the work of ABS journeyman bladesmith Facundo Montenegro of Argentina and Brazilian Rodrigo Sfreddo, the latter the first Latin American accredited ABS master smith. Fisk sees an enthusiasm, a drive that helps set the Brazilians apart. “It’s their hustle,” he asserted.

“One of the reasons they hustle so hard goes back to the fact that you can’t get stuff quite as easily down there, and they have had to rely on innovation. When I first went to Brazil, Ricardo asked me what I needed, what kind of anvil or grinder, and I told him it didn’t matter. We would make knives with whatever they had. It’s not always what equipment is in the shop, but what is in the head, eye and hands.

“Still, years back if you wanted to buy an anvil, you had to buy it here in the United States and ship it there. That was true with grinders and other supplies, too. And you would pay heavy taxes as well. Now, we have businesses making supplies there in Brazil, and that has been encouraging.”

Flavio Ikoma

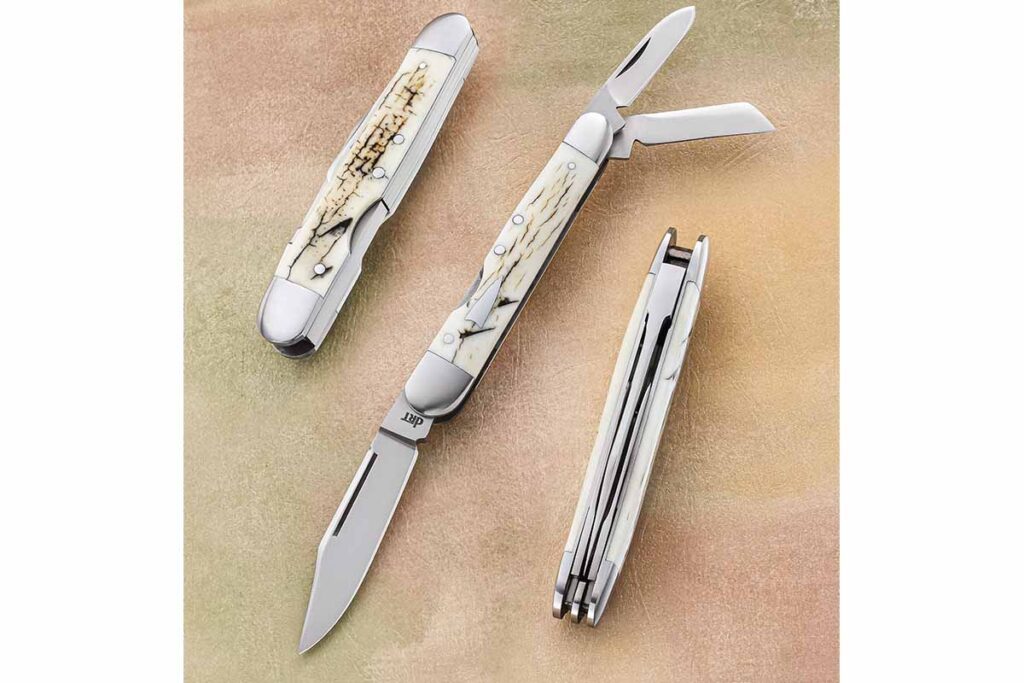

On the factory side, Brazilian Flavio Ikoma has developed a collaborative relationship with Columbia River Knife and Tool, while his apprentice, Pedro Buzetti (page 24), has also come into his own. The Ikoma Korth Bearing System (IKBS), which Flavio helped design along with Ricardo and Paulo Lala, and his Deadbolt locking system are major contributors to the popularity of his CRKT designs. The IKBS, in fact, has revolutionized both custom and factory folders alike.

“Every design of Flavio’s we have uses the IKBS,” remarked CRKT representative Doug Flagg. “His most famous model is the Fossil, and Walmart has sold it for the last seven or eight years. It is amazing because IKBS allows the knife to be opened super fast and the action is incredibly smooth. [Another Flavio] design, the Attaboy, incorporates IKBS. Fitting the bearings in along with Flavio’s patented Deadbolt lock took a herculean effort!”

Flagg and CRKT began their association with Flavio after a tip from BLADE Magazine Cutlery Hall-Of-Fame® member Ken Onion. When Onion mentioned Flavio’s use of bearings in the pivot, he encouraged Flagg to make a phone call to the Brazilian.

“All Flavio wanted was recognition that we would be using IKBS,” Doug commented, “so we agreed and started using IKBS on [the Ripple, another Onion design for CRKT]. IKBS worked great but was hard to mass produce. The original system was individual ball bearings in a milled-out track, and we eventually evolved to caged bearings. Flavio said he would have used caged bearings if they had been available in Brazil. CRKT and most of the industry credit Flavio with putting bearings in the pivot of knives. Also, the Deadbolt is super easy to use and really, really strong. It’s easy to clean out as well. Just unscrew the button and the Deadbolt comes out. Then use compressed air to blow out the crud and reassemble.”

Flavio’s contribution is further evidence of the innovation and skill present in knifemakers and designers from Brazil. “I think they are so good because they have to try harder to penetrate the USA custom knife market,” Flagg reasoned. “They don’t really have a market for high-end custom knives in Brazil, although it is starting to become a thing. Therefore, they have to work really hard and make incredible designs to catch the attention of foreign knife collectors.”

CRKT is working with Pedro to produce current and future offerings. “We have a couple of models in the works with Pedro for 2024,” related Flagg. “As Flavio’s apprentice, he has taken up his own love for knives, and Flavio is now helping him to make custom knives. I expect Pedro to be one of the top makers in the coming years. He is young and absorbing all the knowledge that took Flavio years to acquire. Rick Lala has great designs also. I typically look forward to seeing his knives at the custom knife shows.”

Sobral Brothers

Through Exquisite Knives, custom knife purveyor and retired ABS master smith Dave Ellis has put high-end custom knives in the hands of collectors for many years. He praises the work of the Sobral Brothers, Claudio, Ariel and Marcelo (CAS), of Buenos Aires, Argentina, for setting a standard in bladesmithing excellence.

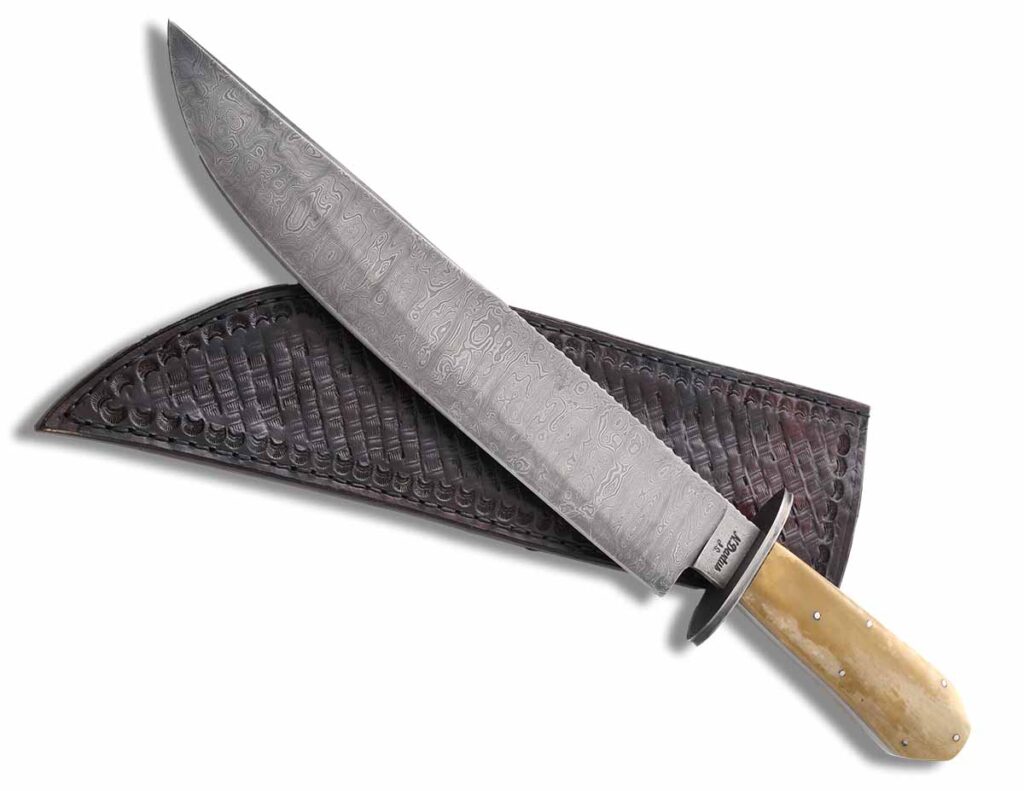

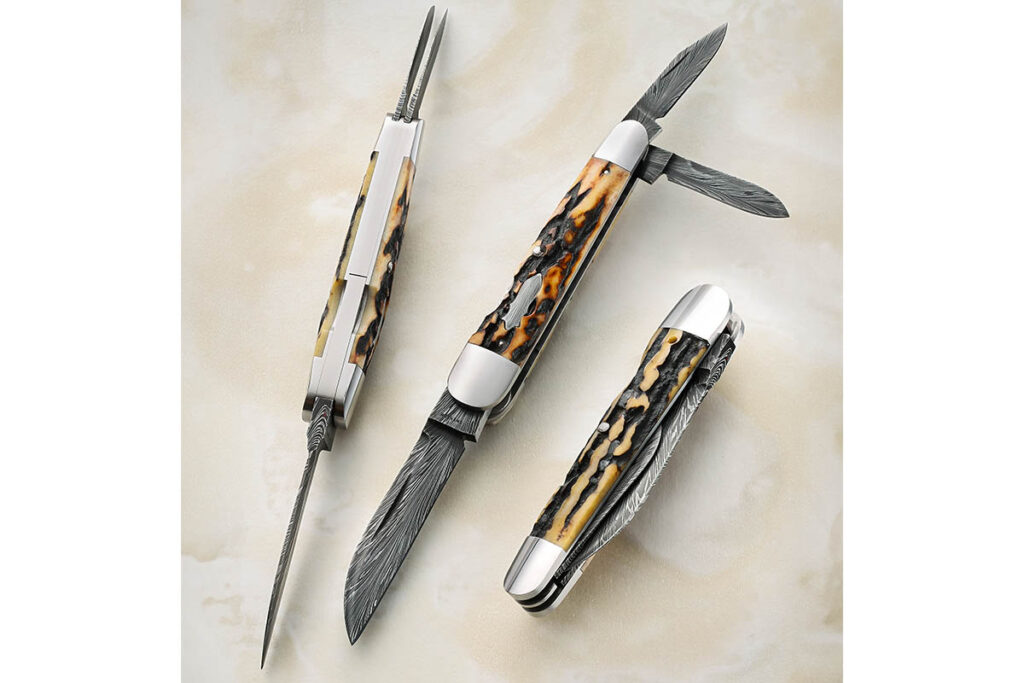

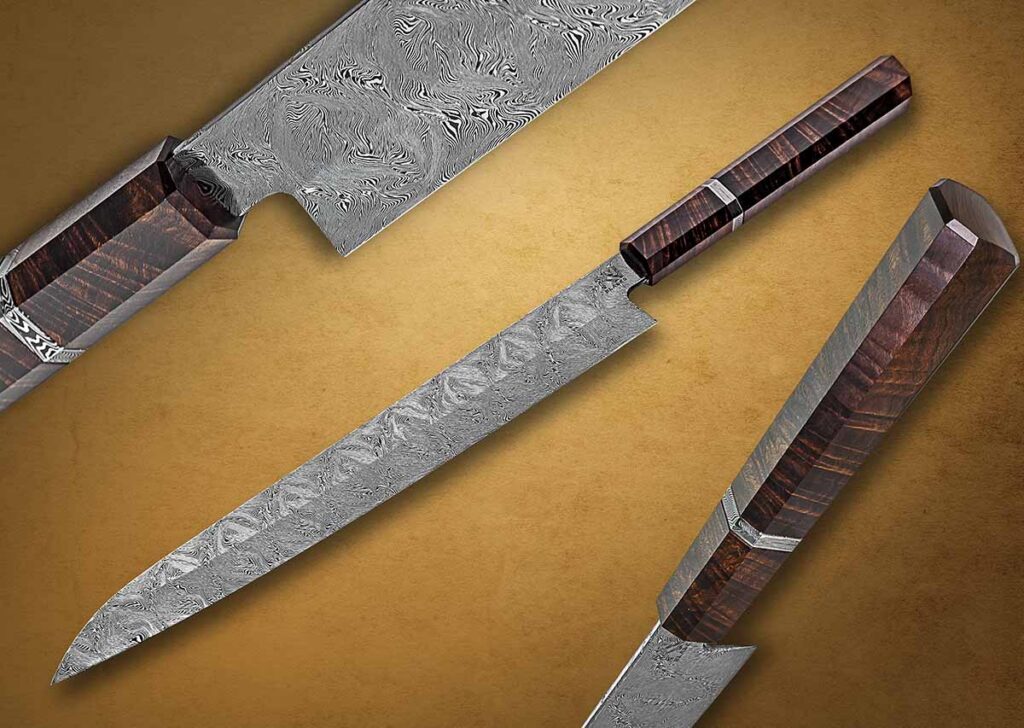

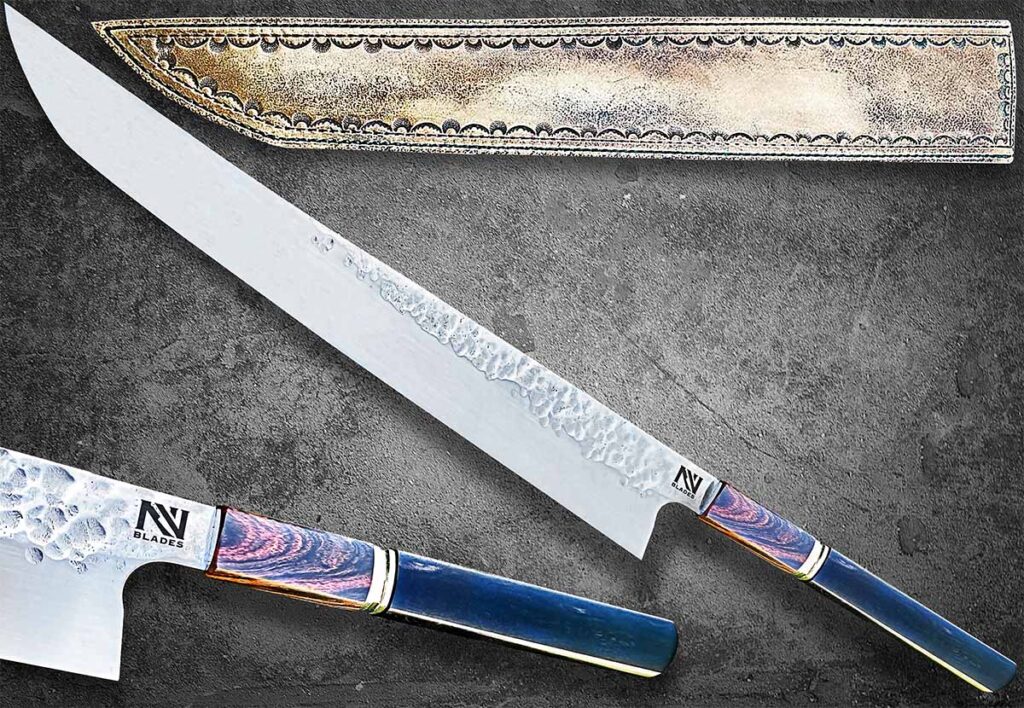

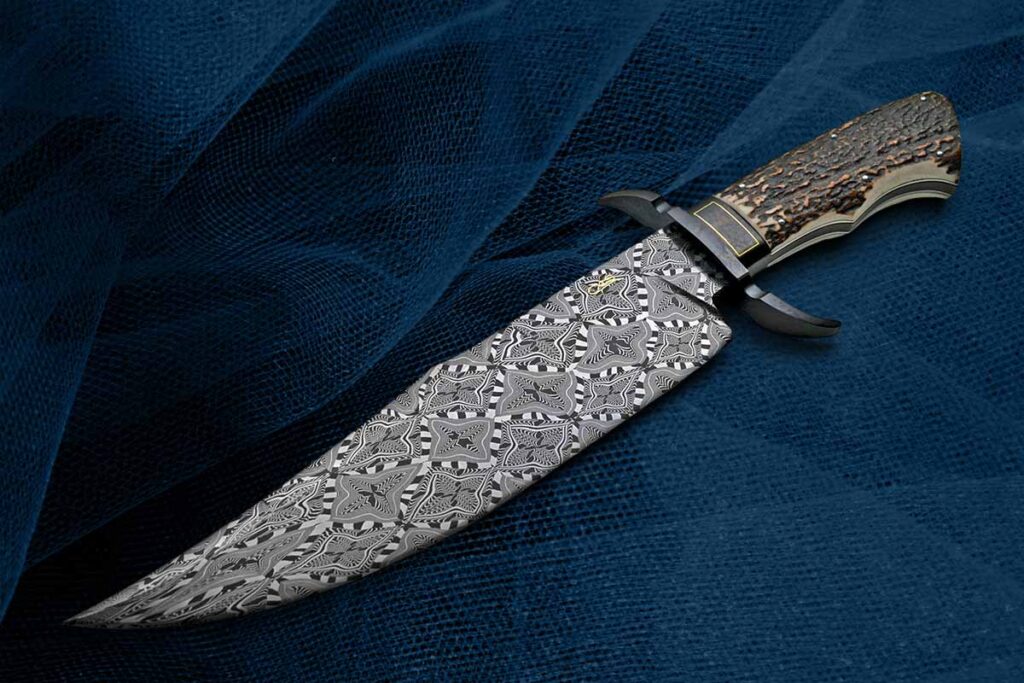

“At first it was their san-mai blades that seemed to attract my clientele,” Ellis explained. “Gradually, as their work progressed, their damascus steel, gun-blued fittings and their stunning designs really put them at the front of the pack. Organic materials are typically utilized for their handles, and Marcelo’s leatherwork has really become a complement to their amazing knives. Bold, dark damascus, as well as intricate mosaic damascus steel draws the eye, and once you hold a knife made by CAS it all comes together!

“They seem to work together seamlessly and produce singular works of art. With three of them working together you can sense the symbiosis that exists and once you meet them, their warmth and enthusiasm are refreshing as well as contagious.”

From wherever it emanates, quality work always speaks for itself. The Latin American bladesmiths and knifemakers have continually enhanced their quality work, and in turn to attract the attention of buyers around the globe.