Recognition, catchiness and marketability are but three keys to knife names.

What’s in a name? A knife by any other name will still cut, hopefully. Many people don’t realize what hangs on a name. Is it good enough to be memorable, catchy as it were? A catchy name will make a knife more or less marketable.

If you’ve read my stories long enough, you’ve seen me comment on a knife’s name, especially if it is a long, drawn-out one. To me, it is important for the name to have a short form. For example, salespeople can’t sell a knife by word of mouth if they have to say the company name followed by Omega Kilroy Uber Cutter, Men In Black Forever Ever Sharp Cutting Commando, etc. When I was having knives licensed, the licensing companies would check to see if there were other knives on the market with the same name to avoid any copyright or other legal problems. They no doubt still do that.

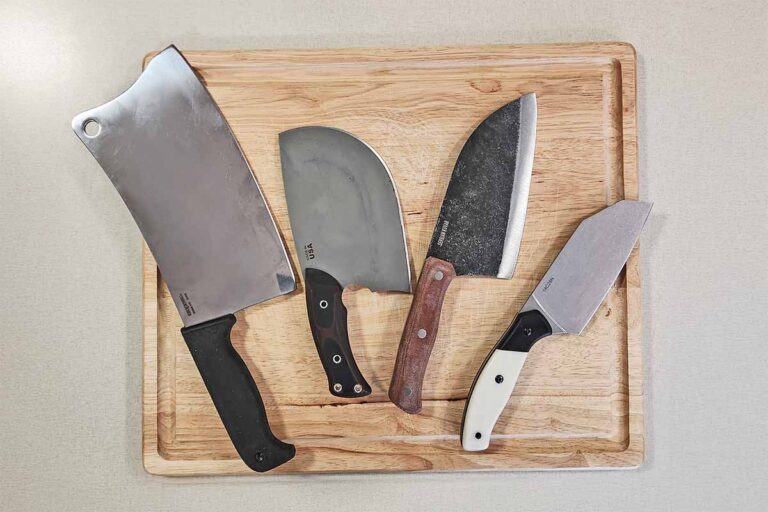

I think now more than ever naming a knife would be even more difficult than designing one. After all, you can have numerous drop points but when you go to name your knife you don’t want it drowning in a sea of cutlery. With so many new knife companies out there, knife production is at an all-time high. How on earth do they make their knives stand out from the rest? One way is with the name. Following are some lighthearted ones.

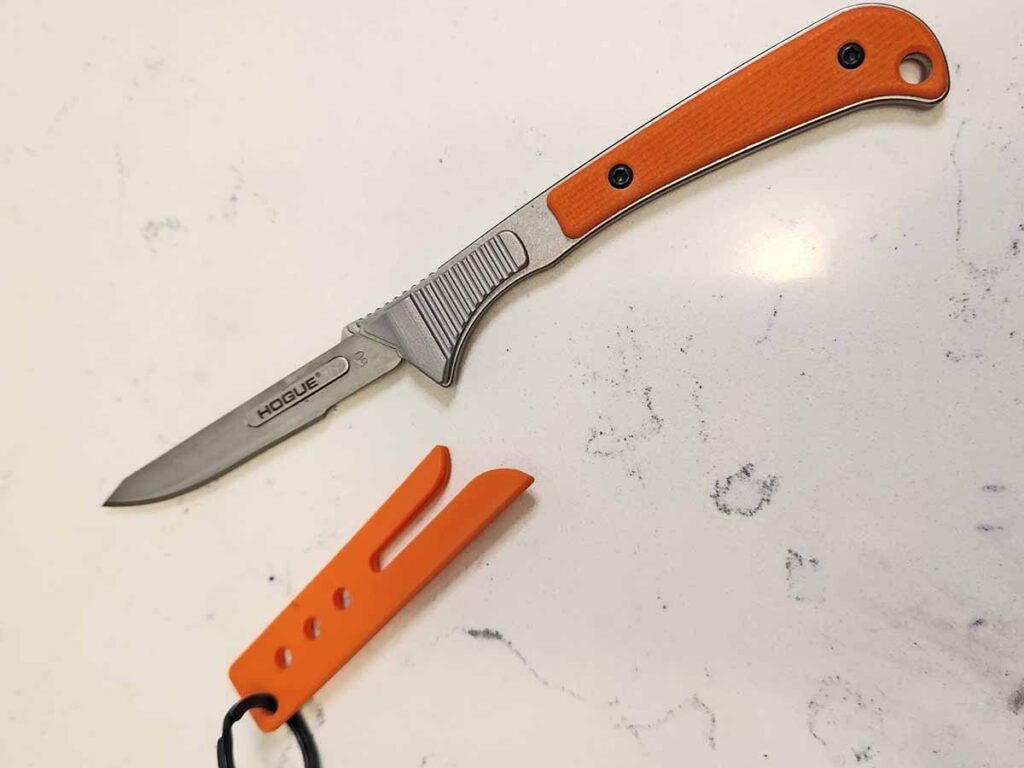

RMJ Tactical Stabby Guy

Stabby Guy Specs

Overall Length: 7.25″

Handle length: 3.5″

Blade Length: 3.75″

Blade Steel: CPM 3V carbon

Handle material: Black G-10, Dirty Olive Hyena Brown

Sheath: Kydex

MSRP: $240

Country Of Origin: U.S.A.

RMJ Tactical chose a name short and sweet for its Stabby Guy. I prefer—no, actually love—names like this. If you find yourself wandering off into multi-syllable diatribes for a name, you’ve lost me. Not only is Stabby Guy brief, it’s to the point, pun totally intended. It is what it says it is. I would call it a self-defense blade. It is slender in design and has an American-style-tanto tip. It is built solid, with the body of the knife having no primary edge.

A fuller runs full length on one side of the blade. The fuller allows the knife to keep its strength and still not weigh a ton. After all, this knife technically is equivalent to a tactical sewing needle. Save the fancy moves for Hollywood and put the machine on surge with the Stabby Guy. It has a simple, ergonomic, basically straight handle. A finger loop at the butt serves to anchor your grip and substitutes for the lack of a guard. A guard stops your hand from slipping forward while thrusting with the knife; the finger loop serves the same purpose.

Though there’s not a lot of edge, the knife need not be dead weight all day while you’re waiting for a prison riot to break out. The small but sharp edge can do a ton of minor chores. However, don’t expect to carve a chess set with it. It has a Kydex sheath equipped with a belt loop. I carried mine in my back pocket and forgot it was there. It’s a cool concept of a knife with a name that doesn’t leave you guessing.

Condor Tool & Knife Rude Boy Machete

Stabby Guy Specs

Overall Length: 7.25″

Handle length: 3.5″

Blade Length: 3.75″

Blade Steel: CPM 3V carbon

Handle material: Black G-10, Dirty Olive Hyena Brown

Sheath: Kydex

MSRP: $240

Country Of Origin: U.S.A.

Condor Tool & Knife’s aptly named Rude Boy Machete is made for light vegetation like that in a rain forest. Some machetes, on the other hand, are geared toward North American vegetation, such as hardwood or softer trees.

People often view a machete as a survival or bushcraft tool. Actually, it is more of a hiking tool with such primary uses as clearing walking trails through the jungle. For these endeavors the knives are often not razor sharp like many in North America believe. Maintaining a high level of sharpness would be next to impossible in such conditions and at best too time consuming. For that reason, a powerful swing with a thin, dull machete works well in dispatching vegetation. The Rude Boy is not only thin but lightweight, making it possible to swing for long periods. The well-constructed leather sheath has a pivoting belt loop to help avoid hanging up easily on vegetation.

The only thing I take issue with is the blade profile. The blade’s lengthy defined tip leaves the belly swell farther back from the end. My preference would be to have the widest part of the blade farthest out to get the most out of the swing. Don’t get me wrong, the Rude Boy worked well, but a long day of swinging makes you want to optimize a blade’s performance. Then again, you do want some variety in appearance.

The best feature is the handle. In profile it is pretty much the American military style, though there are some excellent ergonomics added to the design. The plastic handle is overmolded to create a hidden tang. Instead of being blocky the contours are smoothed out for a comfortable grip you can use for long periods. I like the Rude Boy and I can see me beating the snot out of it once yardwork season arrives.

Toor Knives Jank Shank S

Jank Shank S Specs

Overall Length: 7″

Handle length: 3″

Blade Length: 4″

Blade Steel: CPM M4 carbon

Handle material: G-10

Sheath: Kydex

MSRP: $250

Country Of Origin: U.S.A.

Out of the creatively named test models, I probably gave the Jank Shank S from Toor Knives the longest going over. I used it as an EDC but the bigger workout was when I took it to my sportsman’s club. Many in the tactical crowd promote rings in the handle butt for changing positions during combat, but I like them for the advantage they give while cleaning game. That’s right, cleaning game.

When cleaning animals I often find I want to free my hands to work with the carcass. Instead of putting the knife down, I let it dangle from my pinky. I do what needs to be done and then just move the knife into my grip. There’s no fiddling around; it’s quick, simple and no searching for where I put it down.

My club has an annual muskrat dinner, and depending on ticket sales we clean up to 400 muskrats. I cleaned 50 of the varmints with the Jank Shank S, including splitting open the chest and neckbone. Not once did I sharpen it. When done I cleaned it off, gave it a touch up and bam!—it was crazy sharp again. The textured G-10 scales made it easy to grip despite my hands being covered in blood. It worked so well the muskrats didn’t even complain. I liked it so much you won’t hear me grumble about the blade’s fur-catcher choil. Oh, and did those muskrats ever look good with fries and a side of deluxe baked beans! The sheath fits well with no break-in, period. I will add an UltiClip to the sheath and it will be an instant EDC. The Jank Shank S will make it into my game kit any time. Muskrats beware!

Name-Gamers

A name can add to the appeal of a knife by being entertaining. It is also important to have a good name to make the design stand out and be memorable. In the end you don’t want the name associated with a piece of junk, so it is always best to put the most effort into a great design. Our three name-gamers fill that bill.

Catchy Cutlery Call Signs

- Catchy Cutlery Call Signs

- Altered Beast (V Nives)

- American Lawman (Cold Steel)

- Bot (CRKT)

- Dreadeye (Tactile Knife Co.)

- Juma Blue Snake (Fallkniven)

- June Bug (Emerson Knives, Inc.)

- Laid Back Jack (Jack Wolf Knives)

- Little Bugger (TOPS Knives)

- Monkey Thumper (Fox)

- Separateur (Bastinelli)

- Smooth Criminal (Medford)

- Waning Moon Yataghan (APOC/CAS Iberia)

- Warhead Auto (BRS)

- Zilch Baltic Haze (Gerber)

Pocketknife Info:

- 5 Pocketknife Breakthroughs That Changed The Class Of Knife

- What Makes A Great Pocketknife? The Pros Weigh In

- What Makes The Perfect Pocketknife?

- How To Close A Pocketknife